Lot ID Tracking System

Finale Inventory allows you to create and track your products via lot id tracking. Finale ensures clear traceability of your products and makes it easy to track the lot from the time you receive products into your inventory to the time you sell/ship the specific product. Lot tracking is a critical aspect of product management, particularly for industries that produce perishable goods or goods subject to safety and regulatory requirements. By tracking lots, businesses can quickly and easily identify and isolate products that may have been contaminated, expired, or otherwise compromised, reducing the risk of product recalls and other costly and damaging incidents.

Lot tracking is important because it helps to identify and trace specific batches or groups of products throughout the production, distribution and supply chain process. This information is essential for quality control, regulatory compliance, and in the event of a product recall. Lot tracking software also helps to ensure that products are properly rotated in inventory and that older products are used first, reducing waste and ensuring freshness. Additionally, lot tracking can provide valuable data for forecasting and inventory management.

One of the key benefits of lot tracking is the ability to trace products back to their point of origin. This is particularly important in the event of a recall, where businesses need to quickly identify the source of a problem and take action to remove affected products from the market. Lot tracking also helps businesses comply with regulations that require manufacturers to maintain detailed records of their products and processes.

Create, Track, and Manage Lot IDs with Finale Inventory

Our integrated mobile barcode inventory solution eliminates error and speeds up operations with advanced features like automatic barcode learning and product lookup tables. Picking products with lot ids is a snap with Finale and a mobile barcode scanner.

The inventory complexity compounds when you need to keep track of lot numbers. FInale makes it easy to keep track per-stock-unit information from the start (receiving or manufacturing) to finish (shipping the products). This information is permanently recorded in the system, allowing the company to access the lot id tracking archives later.

Try Finale Inventory Today

If you are in a business where mandates require you to maintain accurate records for each unique lot ids purchase and sales (i.e. medical supplies, fireworks, chemical supplies, pharmaceuticals, etc.), then Finale Inventory is all you need for regulatory compliance documentation. Finale Inventory generates a comprehensive audit trail of stock changes and will accurately track each individual lot sold, received or returned.

Traceability with Lot Tracking

Once a product is assigned a lot, it can be monitored as it moves through your inventory system. A printed or displayed report allows you to search by part number or lot id.

If you manufacture or assemble a finished product requiring lot id tracking, Finale will maintain a log of the component lot id for the full traceability using the unique build operation.

The lot id will be provided on the sales order and manifest for tracking documentation for the customers, as well as (optionally) using barcodes to label the products.

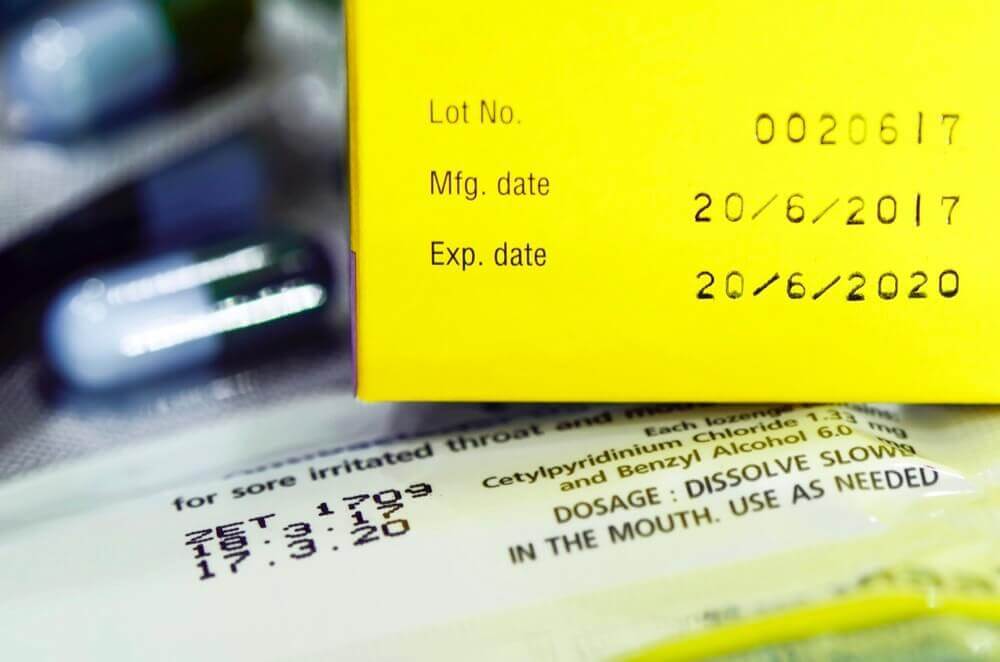

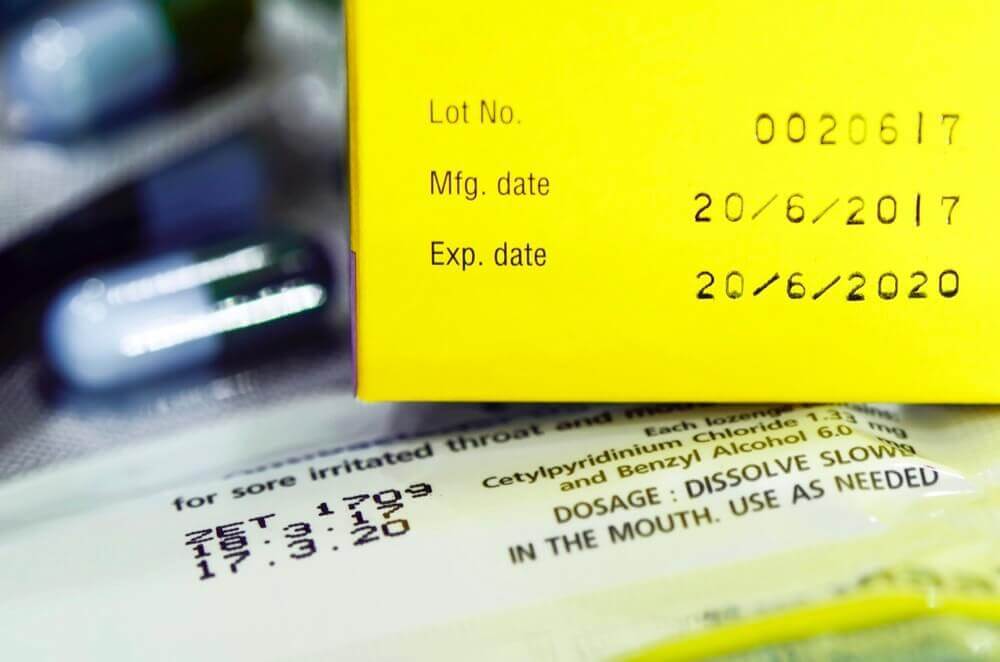

Flexibility with Lot ID Numbering Schemes

Lot IDs are used in a variety of ways, and Finale Inventory is designed to be very flexible and will accommodate a wide range of lot id numbering schemes.

For example, when a product is received with a supplier’s lot id number already on it, the lot id number can be used in one of three ways: it can be assigned as the external lot id number, it can be used as the internal lot id number, or a completely new lot id number can be created.

If a supplier does not provide a lot number, then the user needs to assign one internally. The internal lot number can be assigned through auto-generation or by a user-assigned numbering system. Another common user-assigned practice is using expiry dates for lot ids so the first items can be picked from your available stock first (FIFO).

The choice is yours; Finale supports either scenario for a comprehensive lot ID tracking system.

Straight-forward Lot ID Implementation

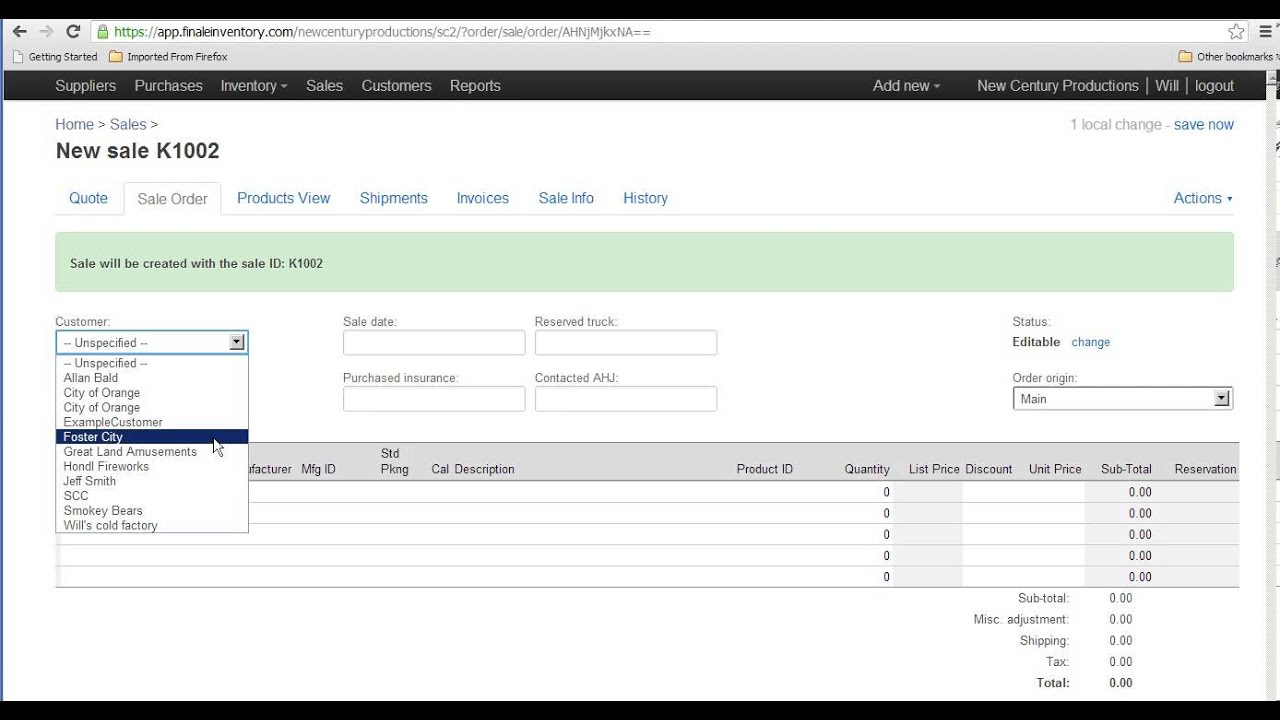

Assigning lot IDs to the products is typically completed when the products are received into the warehouse. Finale makes it easy to assign lots id by offering several options for lots id information to be entered the system.

- Manual Entry: When inbound products are received, simply enter the lot id and assign it to the product.

- Bulk Entry: If you have many lot ids for assignment, importing the data by copying and pasting from Excel.

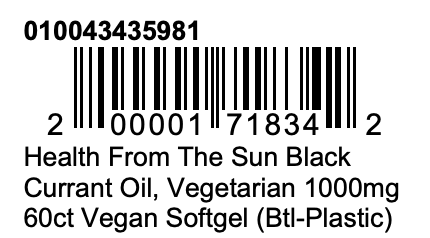

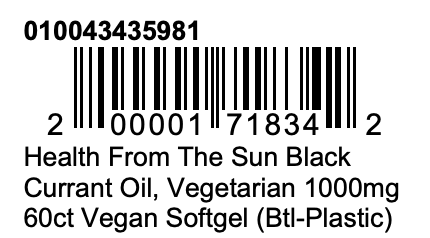

- Mobile Barcode Scanner: The turnkey mobile barcode scanner solution will improve your processing time of inbound shipments while eliminating data entry errors. Recording lot ids is a snap with the barcode scanners. If the lot ids are contained in the barcode on the product, simply scan the barcode. When the lot ids are not given, create and print out barcode labels beforehand. Simply place the labels onto the box and scan the product when the product is received.

To learn more about Lot ID Tracking, check out our following resources:

Examples from Finale's lot tracking software capabilities

To learn more about the lot tracking capabilities of the cloud inventory management, please check out the capabilities and video tour to get more insight to learn if Finale may be a good fit for your application.

Here are videos of using Finale Inventory to keep track of stock items and assets with specific lots.

Stock items with lots/batches

Leveraging the barcode scanner to track the lot id

Difference Between Lots and Serial Numbers