Inventory Management for Manufacturing

Inventory management is critical for any manufacturing company. It's best if you have constant knowledge of the number of components that create your products as well as how many products you have on hand and can produce. Without proper tracking, you won't know when to order more, how many products you need to ship or how many products you can sell.

Having a proper inventory management system in place can save you a lot of time and hassle. You won't have to spend time manually tracking and counting all your stock. Automated and computerized systems help keep your manufacturing on track, up-to-date and accessible to everyone.

Inventory Management for Manufacturing Companies

When it comes to the different types of manufacturing companies, such as discrete manufacturing and process manufacturing, the process for implementing an inventory management system is generally the same. You'll want a program that keeps constant track of the parts or ingredients that come in as well as the finished products that leave.

If your manufacturing company has multiple locations and differing inventories, you'll want a system that can help you manage the inventory in each location as well as a combined inventory. You need to be able to track components and products that transfer from one location to another and even to a distributor facility.

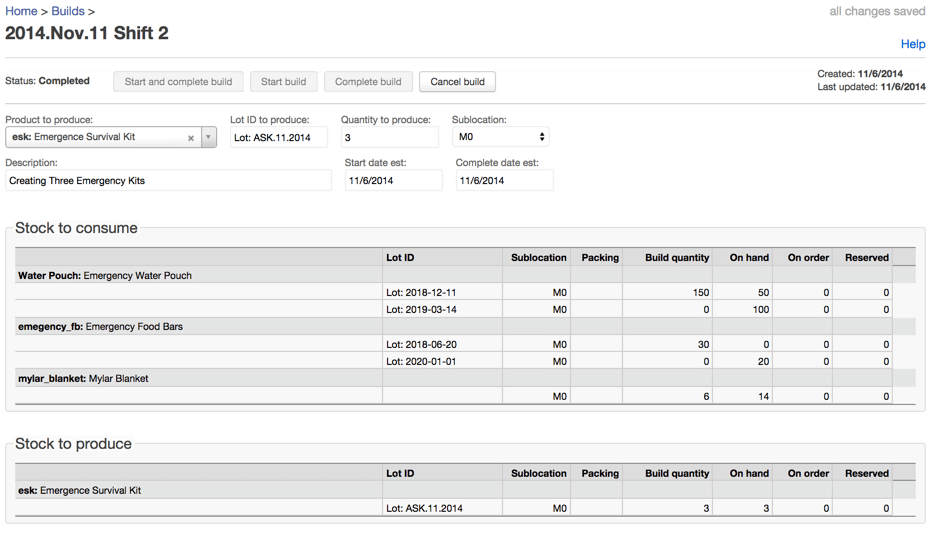

Finale makes it quick and simple to create finished products while tracking the usage of the components and raw materials by using the Builds for Light Assembly or Manufacturing feature. Finale Inventory’s Build module extends the end-to-end processes with specialized capabilities for manufacturers, wholesale distributors and others that need to assemble products or perform basic manufacturing activities to fulfill orders.

The system works from end to end, telling you whether you have the required parts for manufacturing, alerting you when to reorder them and deducting them from your inventory as you use them. This feature is a convenient and efficient way for a company to manage finished goods without a separate, full-scale enterprise resource planning (ERP) system.

Whether your company is large or small, and no matter what you manufacture, you can rely on Finale Inventory to provide you with the best solution for manufacturing inventory management. With Finale, you can easily track every necessary component, ingredient, part and product your business currently has. You'll always have an accurate tally of everything you need when you need it the most and an understanding of what you'll need in the future and when you should place an order.

Creating a Build with Finale Inventory - Video Tutorial

Benefits of Manufacturing Inventory Management With Finale Inventory

When you use Finale's inventory management software, you'll have access to many useful tools that will improve the item management and tracking aspect of your business and can increase employee productivity.

Builds Module and Bills of Materials Software

Sometimes, fulfilling orders involves assembling finished products from various inventory items. To ensure you always have enough parts, use Finale's Builds capabilities to help you track the inventory you use.

When you receive a custom order, our manufacturing inventory software lets you generate a bill of materials showing all the raw materials you need to manufacture the product. If the material is unavailable, you'll receive an alert telling you to order it or when you can expect to receive it. As you manufacture the item, the system automatically deducts the resources from your inventory, allowing you to monitor all the materials you have on hand.

You'll start with making a bill of materials (BOM) in Finale for the items you're assembling. A bill of materials in manufacturing is a detailed list of all the raw materials you'll need to produce or assemble your product. Our manufacturing inventory management system will tell you if you have these components on hand or whether you need to order them separately for a specific job.

Beyond keeping track of your purchases, Builds lets you trace your finished product and all of its components with unique serial numbers. If customers alert you about product malfunctions, you can easily look up the exact items they purchased to determine your next steps for addressing the issue.

Finale's software can support all your build needs, whether you're building in response to customer orders or filling up your warehouse by assembling products in advance.

Full Traceability

One of the most beneficial features of the Builds module is its quick and accurate traceability. When you use a specific lot ID or serial number for your products, the system securely stores each build and allows you to access it whenever you need it. This feature is especially beneficial if a customer contacts you about a potential defect.

The system shows you the exact raw material components used to manufacture each item. Once you pinpoint the source, you can contact your supplier to alert them to the issue and request replacement materials.

Tailored to Fit Your Manufacturing Needs

The Build module works well for all manufacturing companies, whether you build all your inventory as stock items, manufacture your products contingent upon the orders you receive or operate using a combination of both. A build-to-stock system means that you manufacture items based on your inventory levels regardless of customer demand. When you use a build-to-order system, you manufacture an order based on your customer's specific needs.

Build-to-order systems are similar to just-in-time (JIT) programs, operating on lean manufacturing principles to minimize wasted time and maximize material usage. Companies develop JIT programs based on their customers' exact product and volume requirements.

How Finale Inventory Can Help With Manufacturing Inventory Control

Finale Inventory is your one-stop solution for managing your manufacturing inventory. Finale Inventory handles all the small details and lets you focus on other aspects of your manufacturing business. Don't let yourself fall behind with your inventory management. With proper inventory management software, you can keep your company above the rest and maintain quality assurance for you, your employees and your customers.

At Finale Inventory, we know how important inventory management is for any business. Our inventory management solutions integrate all inventory components of your business — plant management, sales, finance, inventory and raw materials procurement.

Schedule a live demo today to learn more about how Finale can help your manufacturing business!

Would You Like to See Finale in Action?

Get started today with a free real-time demo to learn more about Finale Inventory.