Why Is a Lot Number Important?

As your small business grows, there is always more and more information you need to keep track of. Information tracking is important for your business itself, but it is also important for business relations, such as those with customers, investors and buyers. As you gain more popularity and a larger customer following, you’re likely going to see growth in sales and customer demand, which means your stock will expand as well.

As the stock is mainly kept in warehouses and storerooms, the more you have, the more spaces you’ll need to house company products. When you have a larger inventory, you need more warehouses, and when you have more than one warehouse, you need lot numbers. You may be asking yourself why a lot number is important — the answer always comes back to keeping track of your business, products, and information.

- The Importance of Lot Numbers

- What Is a Lot Number in Inventory?

- What is the Meaning of a Lot Number?

- What Exactly Is Lot Control, Then?

- Some Reasons Why a Lot Number Is Important

- Lot Numbers and Inventory Management

- How Finale Can Help

- Partner With Finale Inventory for Reliable Inventory Management

The Importance of Lot Numbers

Say your business sells and distributes food products like lettuce, canned soup or yogurt. Now, imagine that a certain batch of this food product has been released to the market and is subsequently making consumers sick. Maybe there was some sort of contaminant in the food or some issue during production and packaging.

Now that you know this product needs to be recalled, where do you even begin? How do you know which products are affected and which are not? How do you know where the contaminated products ended up? The answer to all of these questions is lot control, or more specifically, lot numbers.

What Is a Lot Number in Inventory?

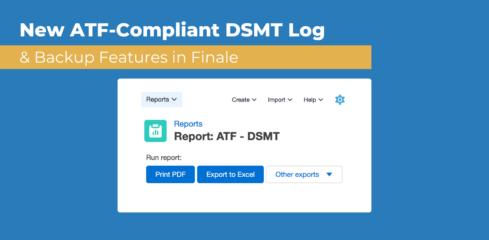

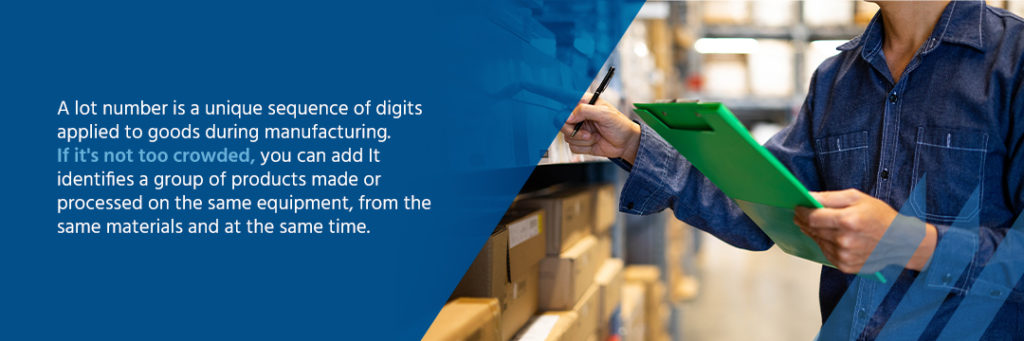

What is a lot number? A lot number is a unique sequence of digits applied to goods during manufacturing. It identifies a group of products made or processed on the same equipment, from the same materials and at the same time. It differs from a serial number in that although every unique product will have a unique serial number, every product in the same lot has the same lot number. The lot number on a single product can trace it back to that particular group.

What is the Meaning of a Lot Number?

On certain items like food products, medicines, perfumes and cosmetics, a lot number may contain an expiry date. The lot number expiration date indicates when the product may begin losing its quality.

Having a lot number in place for each of your warehouses and storerooms gives you some specification when it comes to your products, where they come from and where they have been distributed.

What Exactly Is Lot Control, Then?

Lot control refers to the concept that pieces of inventory can always be traced back to their warehouse and group of origin. The term “lot” simply means the batch or inventory group was manufactured under the same conditions. You can then use this grouping to keep track of your inventory so that if anything happens, like an issued recall, you know how to track and trace the items in question. Lots are most commonly controlled by being issued a certain number to help with tracking.

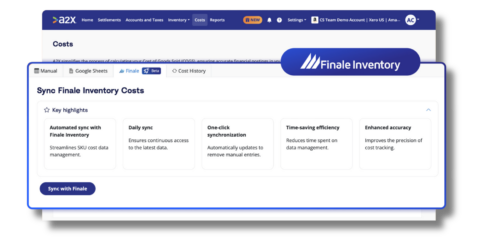

For instance, if your company stocked pet supplies, you could use Finale Inventory to track a batch of pet food with a specific expiration date. You’d merely need to use a barcode scanner to scan the lot number.

Once you recorded the number, you could track information like when you received the bags, who scanned them in, what warehouse you stored them in and when the bags shipped from your warehouse to consumers. You would also receive an alert and be able to pull the food once it was no longer fresh.

Of course, assigning a lot a number to keep track of it sounds simple enough, but things can get confusing the more lots and inventory your business is responsible for. This point brings us back to why a lot number is so important. With a larger inventory, wider distribution radius and higher demand, it becomes more important to have complete control over your products — from the moment they are delivered to the warehouse to when they reach the stores or specific customers.

Some Reasons Why a Lot Number Is Important

There are a lot of reasons why a lot number is important. Aside from helping avoid recall crises, lot numbers also help with inventory management. When you use a cloud-based inventory management system, you can control and manage both your inventory and multiple warehouses, giving you some advantage when you also use lot numbers for lot control. Inventory management is one of the most important parts of your business because it ensures you have the right amount of stock at all times.

There’s really nothing more frustrating to a customer than to find a product they want is out of stock. When this happens, they’re sure to move on to the next business to get what they need.

The meaning and purpose of lot inventory management is to make sure you never over-or under-order products so your warehouses are always stocked well and ready for customer demand. When you add lot numbers into the mix, you gain even more precision with ordering, shipping, reception, and restocking. Some other reasons to have a lot number include:

Recalls

Remember our scenario of the contaminated food products from the beginning of the article? The reality of a recall is more likely and common than you might think. If this ever happens to you, you want to ensure you are on top of the situation as quickly as possible. Whether people are experiencing illness or dealing with a faulty product, you don’t want such items to be on your site, in stores in customers’ hands, negatively affecting them.

If — and perhaps when — a recall needs to be issued, you’ll want to have lot numbers in place to help manage the problem. What’s more, when you use an automated system for inventory management, you can be alerted immediately to lot information, so you can have everything under control in record time.

Product Differentiation

If your business handles products with slight differentiations in color, feel, size, or other criteria, lot numbers for product differentiation are a must. They help you keep track of products that are the same but slightly different and ensure certain materials that don’t match or are dissimilar are not mixed up. Even if some products are incredibly similar, a lot number gives you extra differentiation so you can tell them apart and distribute the right items to the right places.

Expiration Dates

For businesses that sell food and drinks, this is especially important. You want to ensure food and drink products are shipped from the warehouse well before their expiration date approaches you’re sending out a safe and prime product. Thanks to lot numbers, you can also be alerted if an expired product stays in your warehouse for too long so you can dispose of it, order more, and keep your inventory fresh.

Waste Reduction

You may know some of your products are fresher than others because of their lot numbers and expiration dates. In this case, your business could strategize to sell the older — and still good — items first to avoid having to dispose of unsold, expired products.

Lot Numbers and Inventory Management

If you’re looking for a way to get a better hold on lot and inventory management, you will want to try an automated system. Scanning lot numbers instead of recording them manually enable you to ensure accurate records, and you can receive automatic alerts once products reach their lot number expiration date. You can also react swiftly to a recall and pull contaminated product batches to protect consumer health because you know what the lot number means on a product.

How Finale Can Help

Finale Inventory provides small and growing businesses with an excellent system that covers everything from order management to warehouse management across multiple channels. In short, it helps you keep track of your entire business from your computer or the palm of your hand, giving you incredible ease of access and control management. Your clientele will experience impeccable order accuracy and quick fulfillment, and you can build a brand reputation for speed, quality, and customer focus.

If you’re still wondering why a lot number is important, we hope these reasons and more will help you grasp the full scope of why a detailed management system is better than one that doesn’t account for everything. As a small business owner, you want your business to flourish and grow, and we can guarantee something as simple and necessary as using lot numbers can help you reach this goal.

Partner With Finale Inventory for Reliable Inventory Management

To see the benefits of automated, efficient inventory management in your business, contact Finale Inventory. Our cloud-based inventory management system gives you the easy-to-use technological tools you need to monitor what you have on your warehouse shelves, track its movement and replace whole batches if necessary.

We collaborate with thousands of customers, so we know every inventory management application is unique. Our experienced domain experts partner with you to craft a solution that meets your specific business needs, and we pride ourselves on exceeding your expectations with our personalized approach.

To get started with Finale, book a demo, check out pricing, or take a video tour to learn more about how this cloud-based system works for you and your business.