How to Calculate Safety Stock: A Step-by-Step Guide

- What Is Safety Stock?

- Why Your Business Needs Safety Stock

- How to Calculate Safety Stock

- Calculate Safety Stock Using Standard Deviation

- Safety Stock Formula Using Standard Deviation

- Risks Related to Safety Stock

- Learn More About Using Safety Stock With Finale Inventory

One of the first things to know about running a business is that your inventory is an important part of keeping your company alive and thriving. When your inventory is well-stocked and flowing, customers are happy, revenue is coming in and your business is growing. When inventory levels stay elevated, it can lead to significant benefits for your business.

Imagine if the supply chain gets a little tangled — customers may order items you don’t have and have to wait longer for their products or receive the wrong ones. When you have a safety stock, your customers can continue to order items and receive goods at a reasonable rate. You can build trust between your business and your customers with safety stock, driving up revenue and customer retention rates.

When you know how to calculate your safety stock, you can protect your business no matter what happens. Every business should have this safety net in place both as a cautionary business measure and as a way to ensure that your customers are never left hanging or unsatisfied.

Don’t have your safety stock calculated yet? Not to worry — this step-by-step guide will show you everything you need to know about safety stock and how to calculate it for your business’s unique inventory levels.

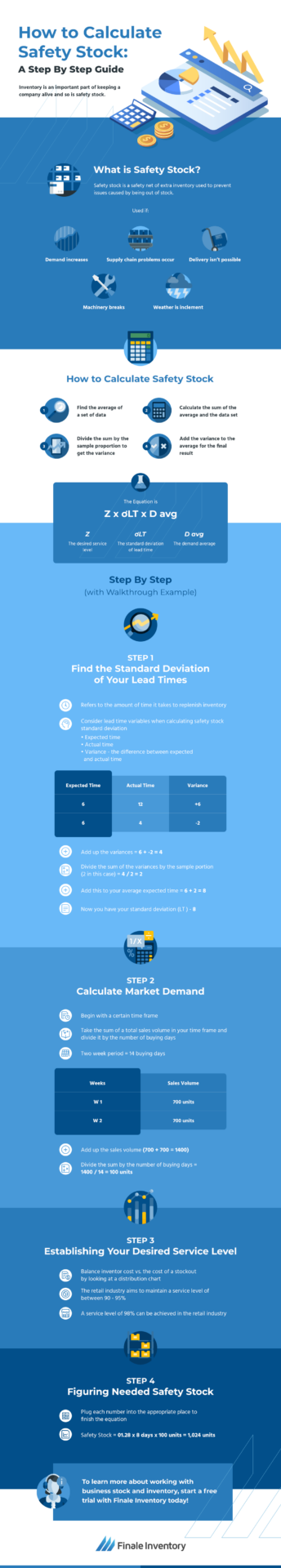

What Is Safety Stock?

The best way to think of safety stock is as a safety net for your inventory. Ideally, your business should never have to worry about running out of stock, but this is not a reality. Demand can increase, problems can arise in the supply chain, your supplier may be unable to deliver when and what you need them to, machinery may break or weather may hinder deliveries.

Any business can run out of stock, which is why you must take precautions now to keep your business running no matter what happens. This is where safety stock comes in.

Safety stock is just extra inventory that is ordered and stored beyond excepted demand. Businesses carry safety stock to prevent issues caused by stockouts, where customer demand is higher than what you expect for a particular product, or there is an incorrect supply and demand forecast or variability in lead times for raw materials.

The purpose of safety stock is to keep your business going no matter what happens, but calculating how much safety stock your particular business will need can be a little tricky. There are many variables involved, and the equation can get a little confusing. Luckily, there are a few ways to accurately calculate safety stock, as well as a comprehensive formula you can use to get perfect results every time.

Why Your Business Needs Safety Stock

Safety stock can help protect your business against unknowns. Owning and running a business comes with risks, but you can decrease stock-related ones by incorporating safety stock into your inventory. Overall, safety stock can help with:

- Accounting for changes in supply: Many factors can prevent changes or delays in your supplier’s production or delivery process, such as poor weather conditions. With safety stock, you can maintain regular business until your supplier is ready.

- Shifting demands: While demand rates change throughout the year due to customer needs, drastic increases in demand can be hard to account for. Safety stock lets you keep items available for customers during these high periods.

- Protecting against price changes: Factors like material scarcity, demand increases and the emergence of new competitors can force stock prices to increase. When you invest in safety stock, your business can function as is without having to buy too much more stock at higher prices.

- Maintaining product quality: When there are fewer products in stock than needed to meet demand, businesses work faster to put products out for customers. This can lead to overlooked damages or low-quality products, which can reduce customer satisfaction.

How to Calculate Safety Stock

You may think that just eyeballing your safety stock needs and making an educated guess on how much extra stock to keep would be enough to keep things on track, but this is one of the most dangerous things you can do. If you do not properly calculate safety stock, you can increase the risk of a stockout.

If your customers find that your business is not meeting demand, they’ll find another establishment that can. With this in mind, you should take calculating safety stock very seriously to avoid problems that could take a long time to fix. When you do calculate safety stock, you can look forward to increased revenue and a much higher service level.

Service level refers to the likelihood that the amount of stock you have on hand during lead time will be enough to meet your expected demand. In other words, a high service level means that a stockout won’t easily occur. So, how do you calculate safety stock? Let’s break it down.

Calculate Safety Stock Using Standard Deviation

To calculate safety stock, you must do the following:

- Find the average of a set of data

- Calculate the sum of the average and the data set

- Divide the sum by the sample proportion to get the variance

- Add the variance to the average for the final result

Safety Stock Formula Using Standard Deviation

The safety stock equation looks like the following: Z × σLT × D avg

To break this down further: Z represents the desired service level, while σLT is the standard deviation of lead time, and D avg is the demand average. It may sound a little complicated, but you can do it fairly easily with a little help. Let’s get started.

Step by Step

Follow these steps for your safety stock calculation:

1. Calculating Lead Time

Lead time refers to the time between the initiation and completion of a production process — the amount of time it takes to replenish your inventory. In short, you have to think about the total amount of time it takes to submit a purchase requisition, have that requisition approved, email vendors, deliver products from vendors, inspect products, put the product on shelves or update online stock levels.

To calculate the lead time for safety stock, however, you have to think about lead time variables. This means that lead times usually won’t be the same from cycle to cycle. To keep track of all this, create a table with the following three categories:

- Expected time or the expected lead time of a certain product.

- Actual time or the actual, real-time it took to replenish the order of a certain product.

- Variance or the difference between the actual time and the expected time.

If you have positive numbers in your variance category, they represent the number of days over the expected times. If you have negative numbers in the category, then the delivery arrived earlier than the expected time. With these numbers and meanings in tow, you can then find the standard deviation for your lead times.

To do this, add up all the variances. Then, take the sum of the variances and divide them by your portion numbers, meaning the lead times of the past few shipments — if you have five past shipments in your portion, you will divide the sum by five. Next, add this result to the average expected time. Now, you have the standard deviation for the lead time.

2. Calculating Market Demand

To calculate the demand average, you must begin with a certain time frame. This can be a week or two, or a month and longer. The best time frame to work with is how quickly you can reorder a product. To calculate demand average, you need to take the sum of a total sales volume in your time frame and divide it by the number of buying days. In a two-week period, the number of buying days would be 14.

3. Establish Your Desired Service level

Before you can finally determine safety stock, you must consider Z or the service level. To do this correctly, you have to balance inventory cost versus the cost of a stockout.

4. Figuring Needed Safety Stock

Now that you have your lead time and average demand time calculated and your desired service levels established, you can complete the equation and calculate your safety stock. Remember that Z represents service level, σLT represents the standard deviation of lead time, and D avg represents demand average.

When you have all the accurate variables, you can plug them into the calculation, and learn exactly what your safety stock should be for your unique business. Before we move on to our example, let’s recap each of piece of our equation:

Z: In the retail industry, the typical desired service level is 90%. In some cases, higher priority products may reach a service level of 95%. To get a decimal number of your desired service level, refer to a distribution chart. A normal distribution chart will show at 90% service level converts to a service factor of 01.28 – this number will represent Z in the equation.

Z = 01.28

σLT: To calculate demand average, you must begin with a certain time frame. This can be a week or two, a month or beyond. The best time frame to work with is how quickly a product is reordered. To calculate demand average, you have to take the sum of a total sales volume in your time frame and divide it by the number of buying days. In a one-week period, for example, the number of buying days would be seven.

σLT = 7

D avg: Say in a one-week period, you have a sales volume of 500 units with volume increasing by 100 units each week. This means that week 1 would be 500 units, week 2 would be 600 units, week 3 would be 700 units, and week 4 would be 800 units. You would then calculate the total number of sales volume for the whole month, or 500+600+700+800=2600.

You would then divide the sales volume by the number of buying days, which is 30.

2600 ÷ 30 = 86.7 units

D avg = 86.7 units

As we move forward, you would plug each number into the appropriate place, and the final equation will look like the following:

Safety Stock = Z x σLT x D avg

Safety Stock = 01.28 x 7 days x 86.7 = 776.8 units

Why You Should Use the Safety Stock Formula

Using a safety stock formula can help you tailor your inventory needs to best fit your business. By incorporating factors from your industry and allowing for changes in the market, your company will maintain business during times of change.

When using a safety stock inventory formula, curating a formula that best fits your industry and the different factors involved is essential. While a standard formula is great in demonstrating examples, using a procedure specific to your industry can help account for adjustments in factors likes upstream failure, order period and order quality requirements.

Your business can significantly benefit from a specific, well-tailored safety stock formula when used correctly. You can see increases in many different areas, including higher revenue, customer retention rates and efficiency. Additionally, safety stock can help ease tensions and better relationships with your suppliers and customers.

Risks Related to Safety Stock

Safety stock can greatly benefit your business and overall performance. However, there are some common mistakes you will want to avoid to best utilize safety stock:

- Eliminating stockouts: Many companies use safety stock to completely eliminate the possibility of a stockout when safety stock instead helps prevent their impacts. Try focusing on balancing your costs and service levels instead to best prepare for stockouts.

- Reflecting changes in supplier lead time: While safety stock can help in instances of changes in lead time, you should not determine safety stock levels on current changes in lead time. Instead, use a standard deviation time when calculating your safety stock to best accommodate possible fluctuations in lead time.

- Incorporating no safety stock: While some businesses try to cut safety stock levels to reduce inventory levels and extra inventory costs, this will ultimately leave them unprepared for other situations, leading to increased costs and decreased customer satisfaction.

Learn More About Using Safety Stock With Finale Inventory

With careful planning and preparation, you can calculate safety stock accurately every time and see the benefits that safety stock inventory can bring to your business. At Finale Inventory, we can help you understand your inventory needs for your business. Start a free trial with Finale Inventory today to learn more about working with business stock and inventory.