Stock Take Software

Accurate Counts With a Powerful Stock Take Software

Get accurate inventory counts without the hassle of spreadsheets. Finale’s stock take software makes it easy to track quantities, prevent overselling, and improve your bottom line.

Easier Cycle Counts - No More Discrepancies

Stock Take Software Built for Ecommerce Sellers

Multichannel ecommerce sellers often rely on spreadsheets or basic tools like Shopify and QuickBooks to manage inventory counts. These methods don’t update in real time and quickly become a liability when selling across multiple platforms. Without regular stock takes, inventory records naturally drift due to mispicks, shrinkage, returns, or human error. That drift leads to overselling, canceled orders, poor customer reviews, and even penalties on marketplaces like Amazon.

Finale connects your selling channels—Shopify, eBay, Amazon, and more—into one centralized system where stock counts are automatically recorded and synced. Whether you're counting manually or using barcode scanners, Finale supports frequent cycle counts to keep your inventory accurate across all locations. By helping teams catch mismatches early and update inventory everywhere at once, Finale prevents overselling, improves customer satisfaction, and reduces the manual work of keeping multiple systems in sync.

Order Fulfillment Accuracy

Accurate inventory data means better order fulfillment. When your system reflects actual stock levels, you reduce stockouts and backorders, leading to fewer customer complaints and increased trust in your brand.

Regular stock takes help ensure this accuracy by identifying discrepancies between recorded and physical inventory. This lets you correct errors before they impact orders, improving pick accuracy and fulfillment speed.

Finale Inventory. The Ultimate Stock Take Software.

Discrepancy Tracking & Shrink Reduction

When inventory counts don’t match what's expected, it’s often unclear whether the issue is due to theft, damage, returns, or administrative error. Without visibility into stock history, loss patterns go undetected and continue to affect profitability.

Finale provides a complete audit trail for every inventory movement, helping teams pinpoint the source of discrepancies. With this visibility, you can address root causes, improve accountability, and reduce future shrinkage.

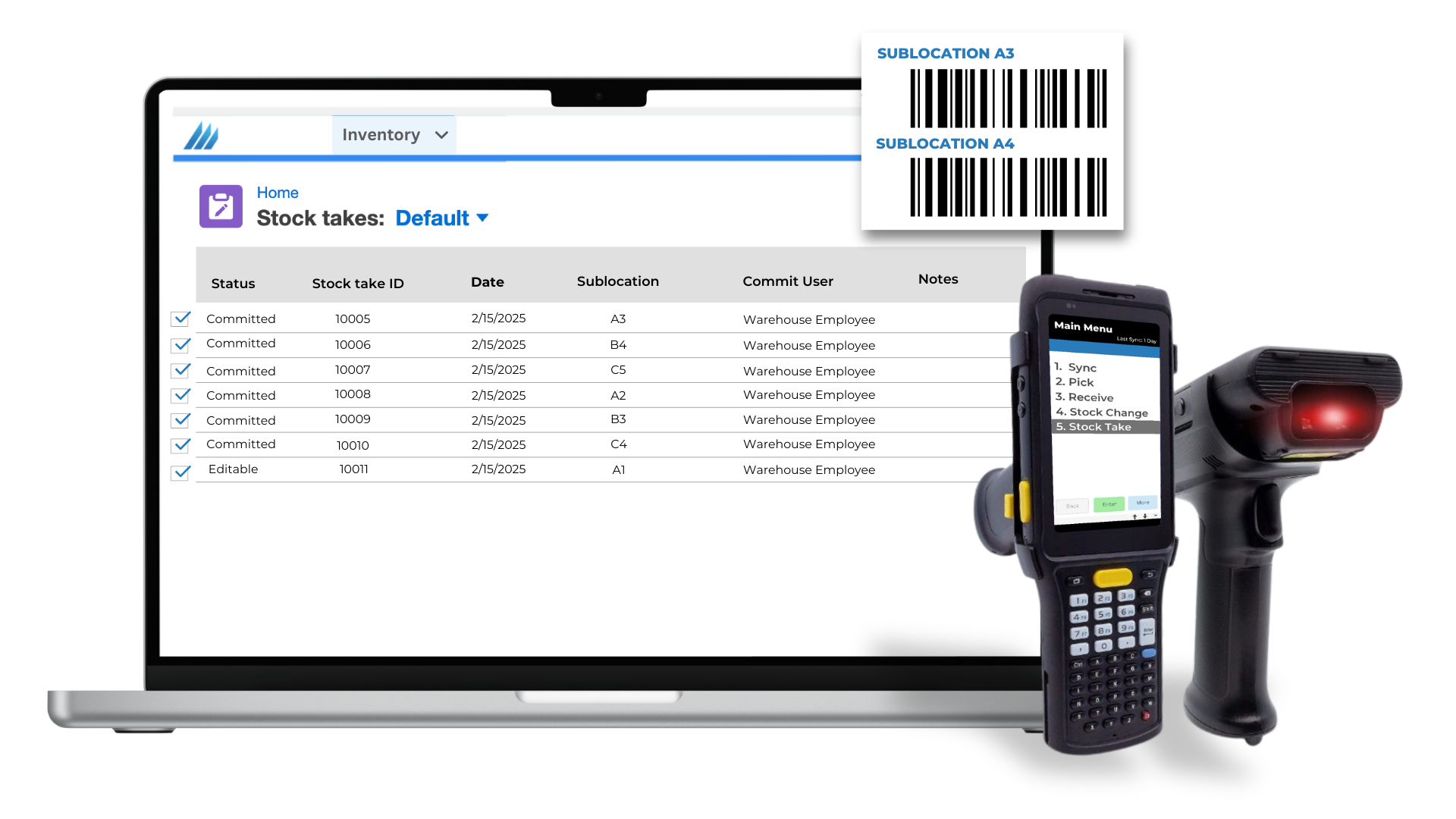

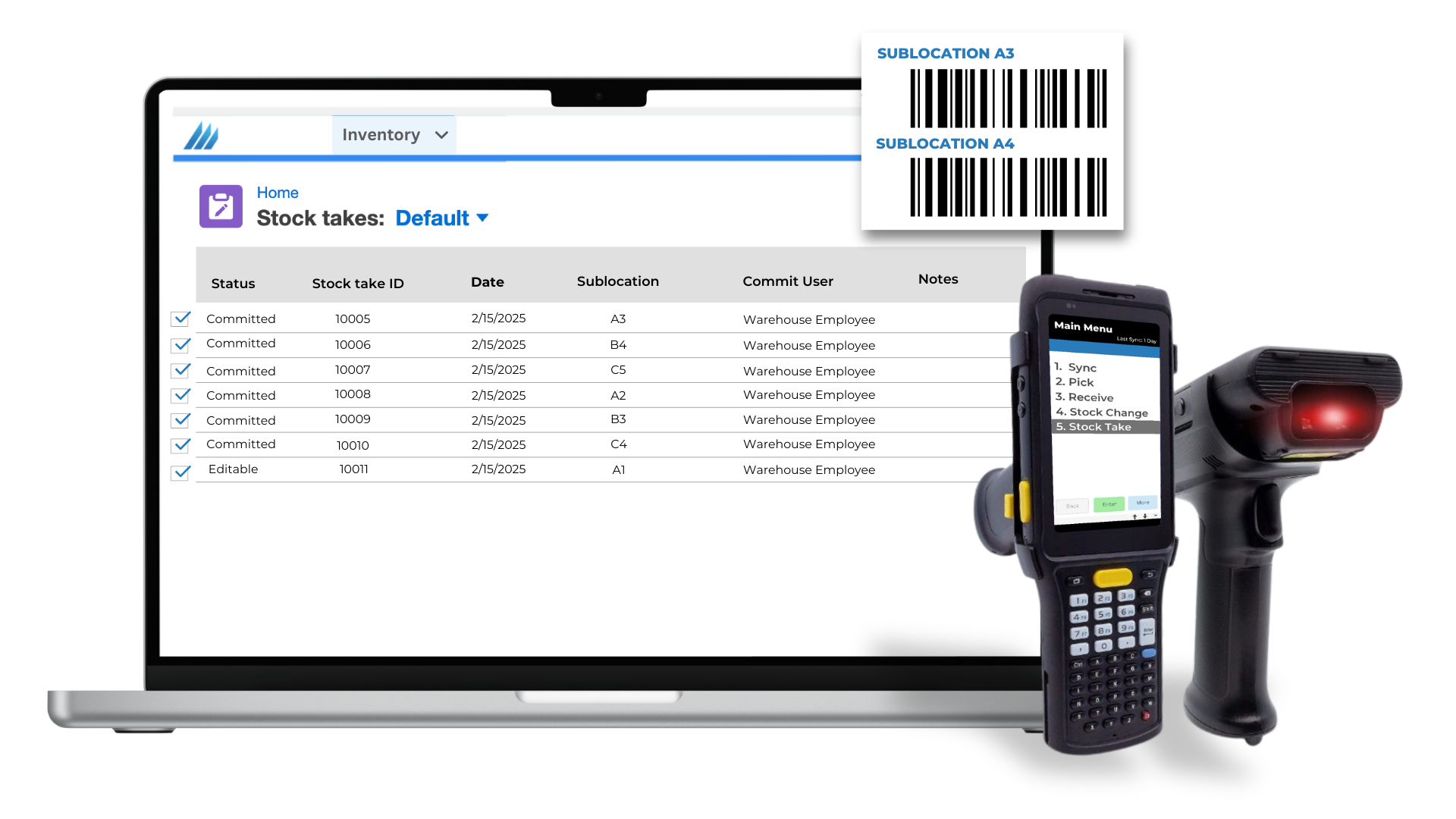

Cycle Counts & Stock Takes With Barcode Scanning

Manually walking through the warehouse with spreadsheets to perform counts is time-intensive and disruptive to daily operations. This is especially true for large product catalogs.

Finale’s built-in tools are also made for efficiency. Users can upload and reconcile stock counts, conduct checks, and track variances faster than spreadsheets alone. Supercharge your warehouse operations with Finale’s mobile barcode scanner, which boosts cycle count speed and accuracy.

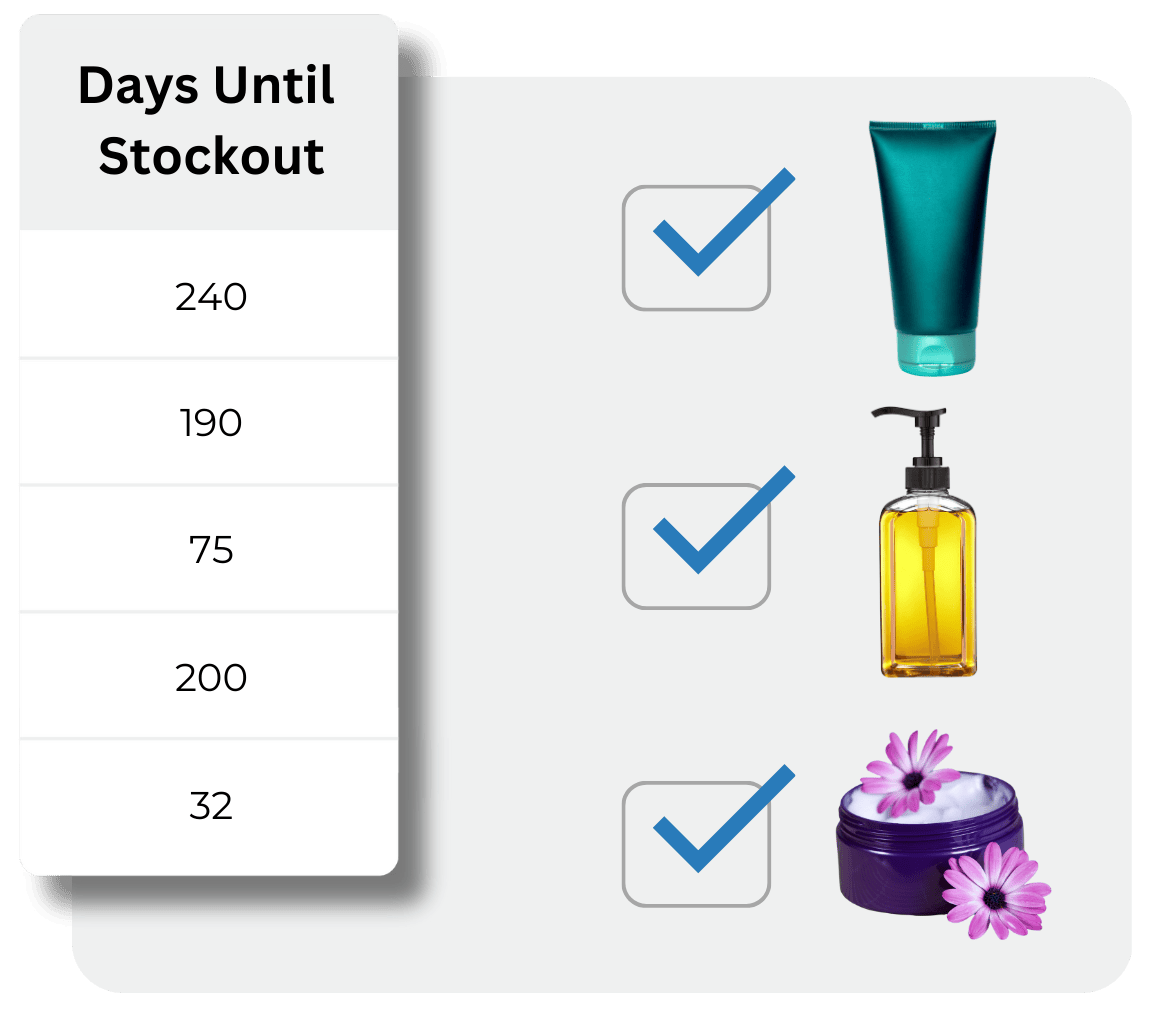

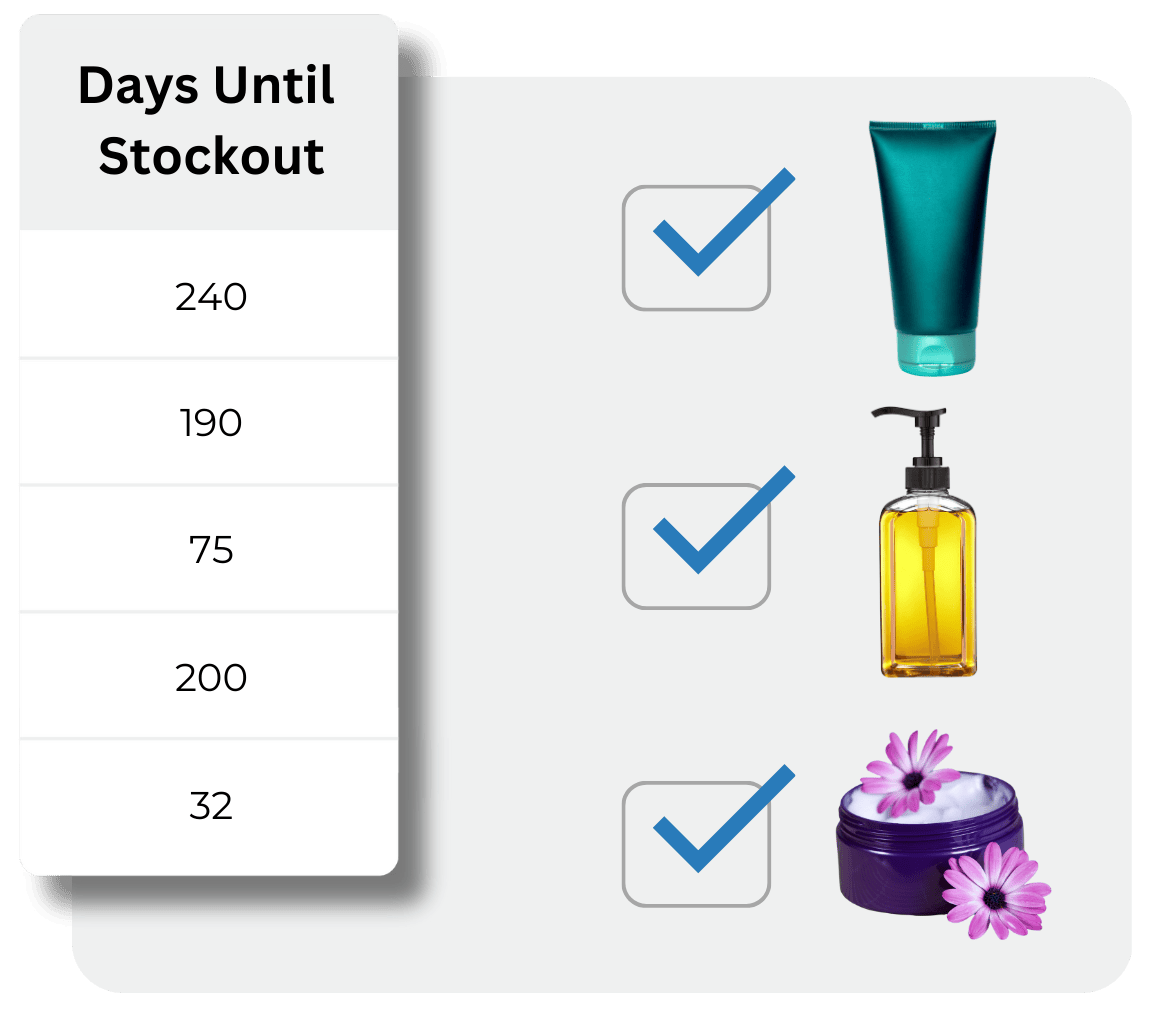

Purchasing & Reorder Recommendations

Without an accurate count, you risk overstocking slow-moving items or understocking bestsellers. Stock takes give purchasing teams a reliable foundation from which to reorder. Physical counts help ensure your replenishment decisions are based on facts, not assumptions.

They also surface trends in inventory shrinkage, miscounts, or procedural gaps that might otherwise go unnoticed. By regularly validating stock levels, you can fine-tune purchasing strategies and avoid tying up capital in the wrong products.

Inventory Financial Reporting

When inventory values are inaccurate, key financial metrics like COGS and gross margin become unreliable. Without regular stock takes, what's on the books may not match what's on the shelves—making audits difficult and financial statements less accurate.

Finale’s stock take software provides a centralized place to record counts and automatically reconcile them. These updates flow directly into your financial data, improving the accuracy of metrics like COGS and gross margin and supporting audit-ready financial reporting.

"I used to do stock takes with pen and paper. Using Finale and a mobile barcode scanner, I get it done in half the time...I never would have finished doing stock takes for my 60 sublocations without the scanner and Finale. A must-have for any small business looking to save time with inventory management."

A stock take, or physical inventory count, is the process of verifying the actual quantity of items in your warehouse and comparing it to the quantities recorded in your system. Without stock take software, this process is often done manually using clipboards or spreadsheets, which can be time-consuming and prone to errors, especially with multiple warehouses. For example, a business might have staff walk through aisles writing down quantities and manually enter those numbers into a spreadsheet for later reconciliation. Finale Inventory can record stock takes using barcode scanners or mobile devices. Users can scan items directly into the system, enter counts, and instantly see variances between recorded and actual quantities. Finale supports shelf or zone cycle counting, allowing you to check small inventory sections regularly without shutting down operations. Many sellers like to do cycle counts for high-volume or high-margin items to make sure they are always stocked.

This ensures orders can be fulfilled correctly and on time, inventory valuation remains accurate, and purchasing decisions are based on reliable data. In this way, stock take software doesn't just improve the counting process—it enhances the accuracy and efficiency of your entire business operation.

Watch this video about stock takes and cycle counts in Finale Inventory.

Once all your SKUs are mapped in Finale Inventory, you can use a mobile barcode scanner to log the quantity. You can do individual scans for large items or you can scan the barcode once and type in the quantity on the scanner.

Learn more about stock takes, stock counts, and cycle counts with the barcode scanner.

Yes! If you conduct a stock take or cycle count and you find you are low, Finale Inventory has a built-in reordering tool. Depending on your business, restocking or reordering can be configured in different ways.

Yes! We have built-in stock valuation since Finale tracks your cost of goods sold (COGS), purchase orders, landed costs, average cost, and stock levels. This gives you clear visibility over the true value of your inventory.

Learn more about stock valuation, inventory accounting, and financial reporting.