Multi-Warehouse Inventory Management

Simplify Your Business - Inventory Systems for Warehouses With Multiple Locations

Get visibility of all your stock with Finale Inventory, no matter where it is. This solution is made for businesses juggling inventory across multiple warehouses, retail locations, and fulfillment centers.

Complex Warehouse Management Made Easy

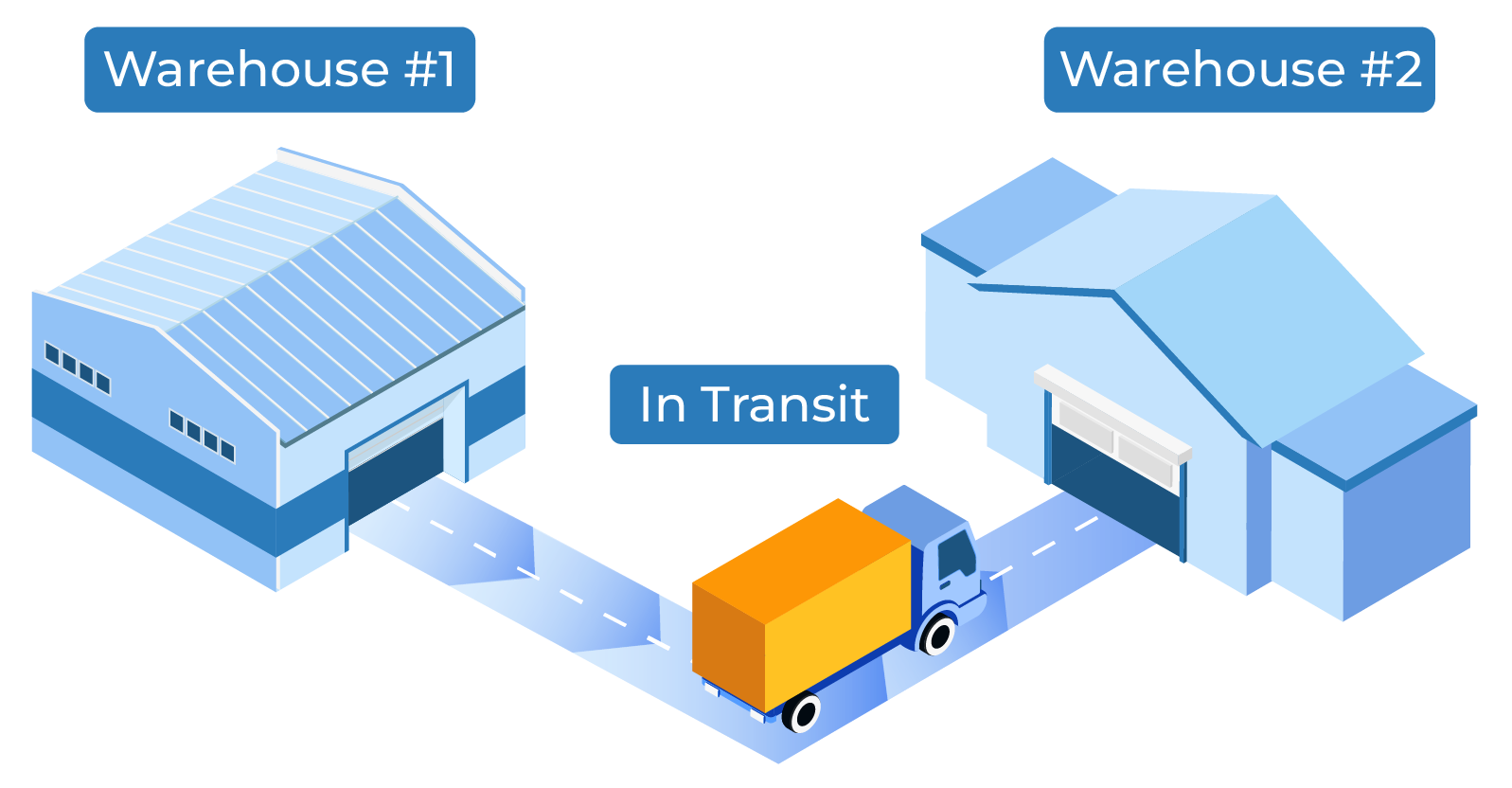

Multi-Warehouse Inventory Valuation & Visibility

Finale provides real-time visibility into your inventory’s value and quantity across multiple warehouses or brick-and-mortar stores, ensuring you always know where your stock is, what it’s worth, and how quickly it’s turning over.

Even as shipments move between locations, Finale tracks both the number of units and their total dollar value in transit, giving you a complete picture of your inventory at every stage.

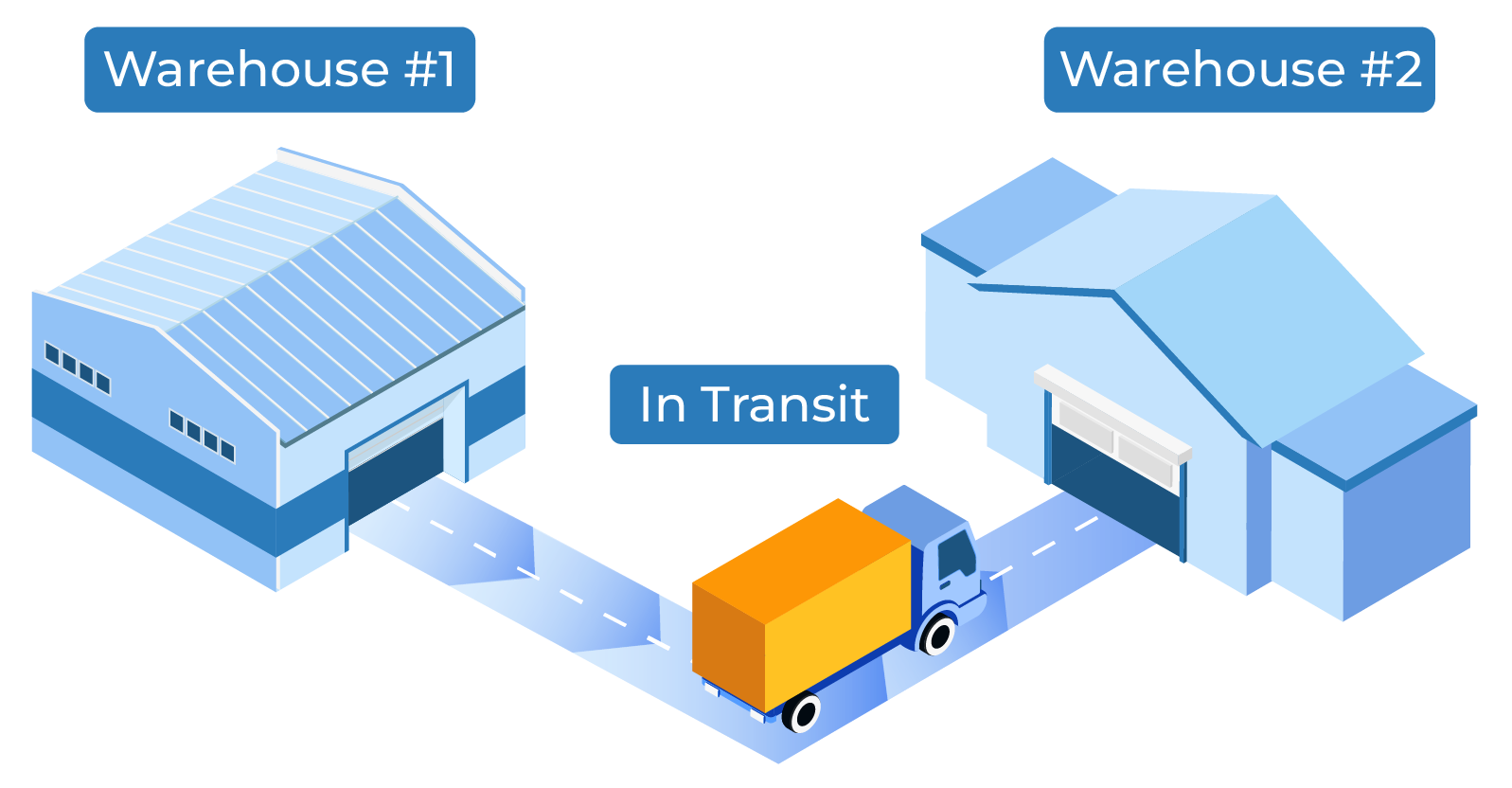

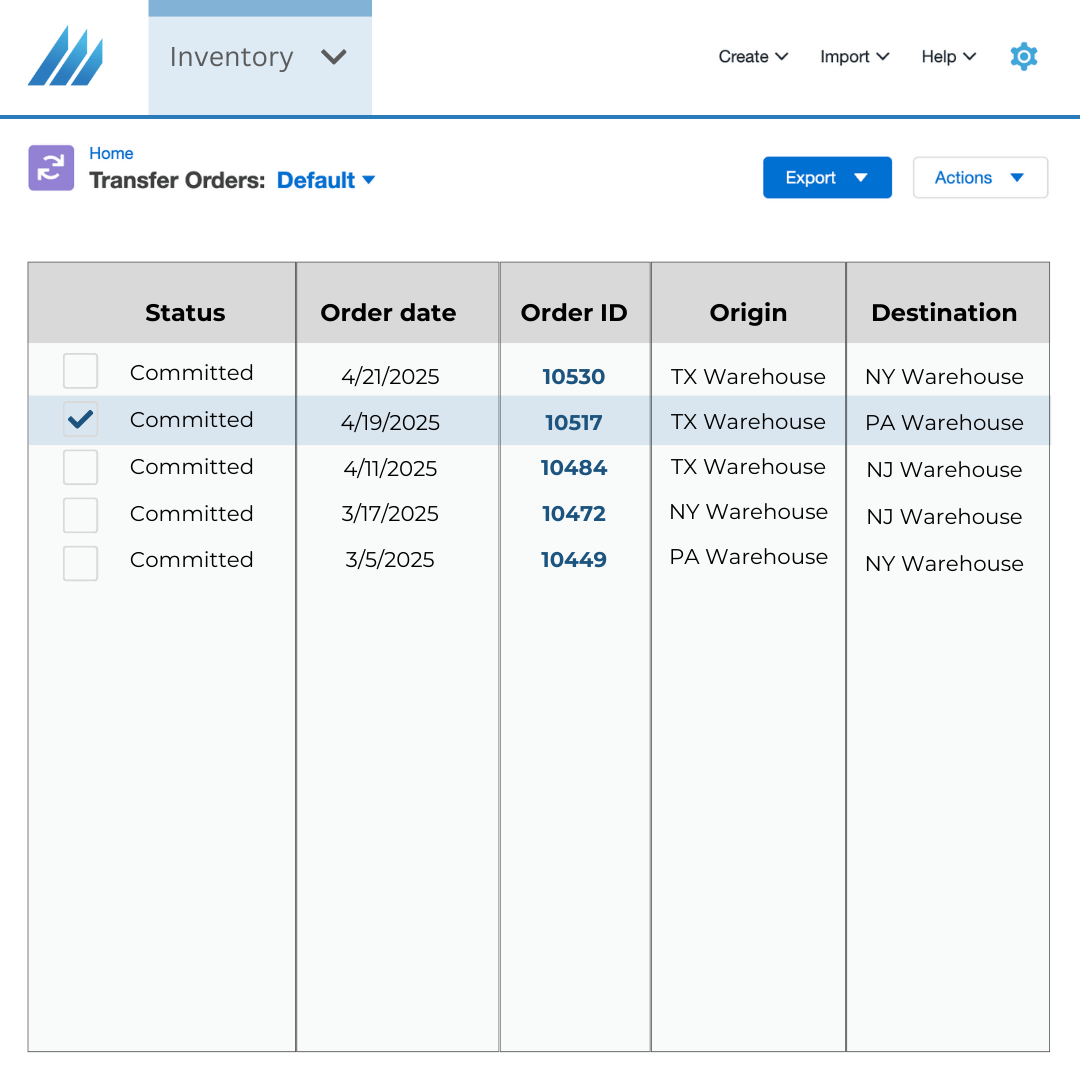

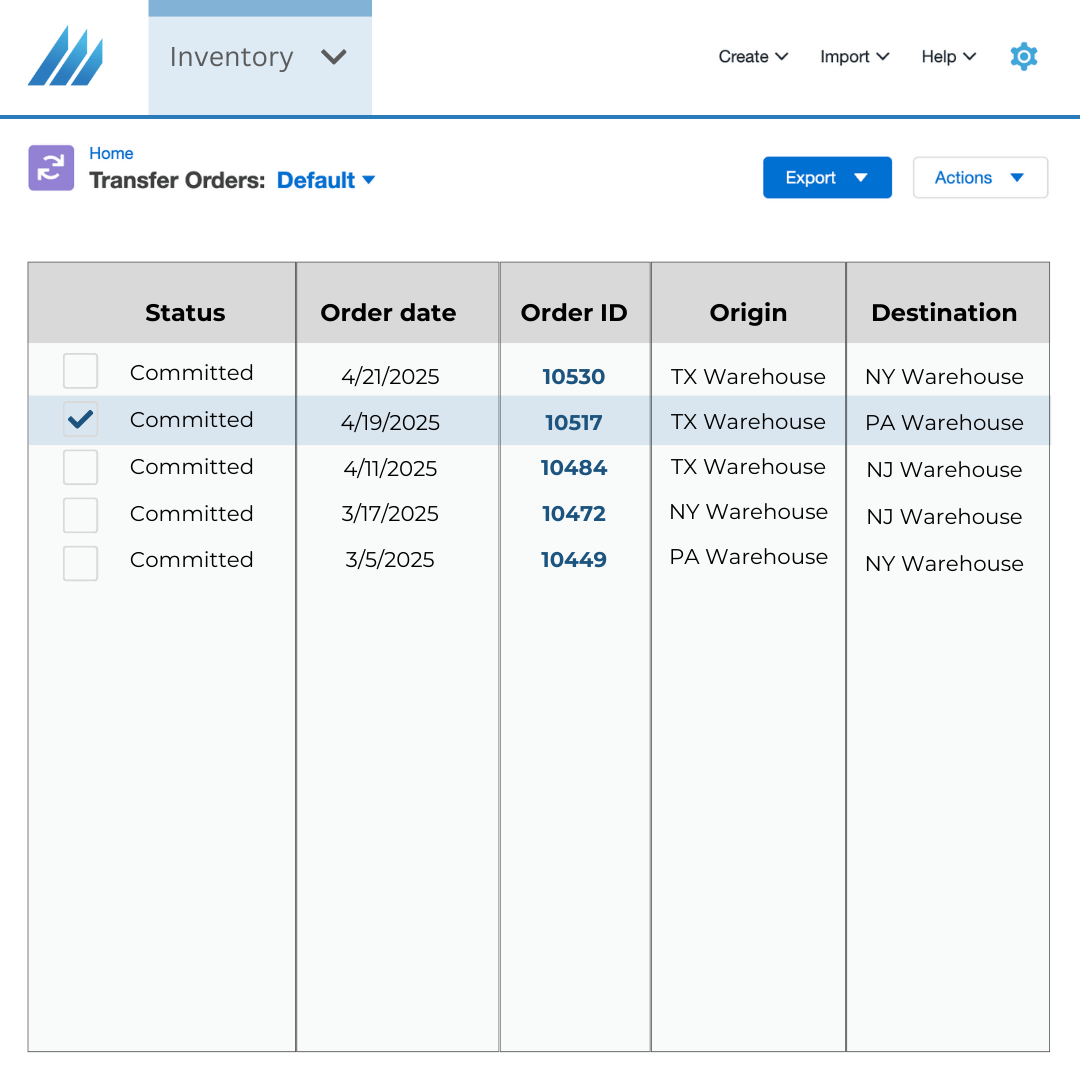

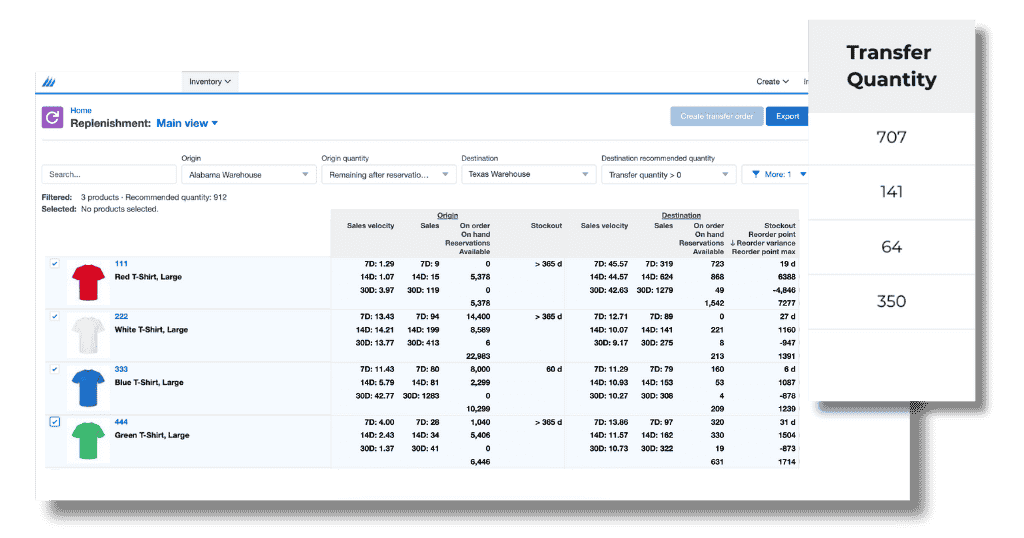

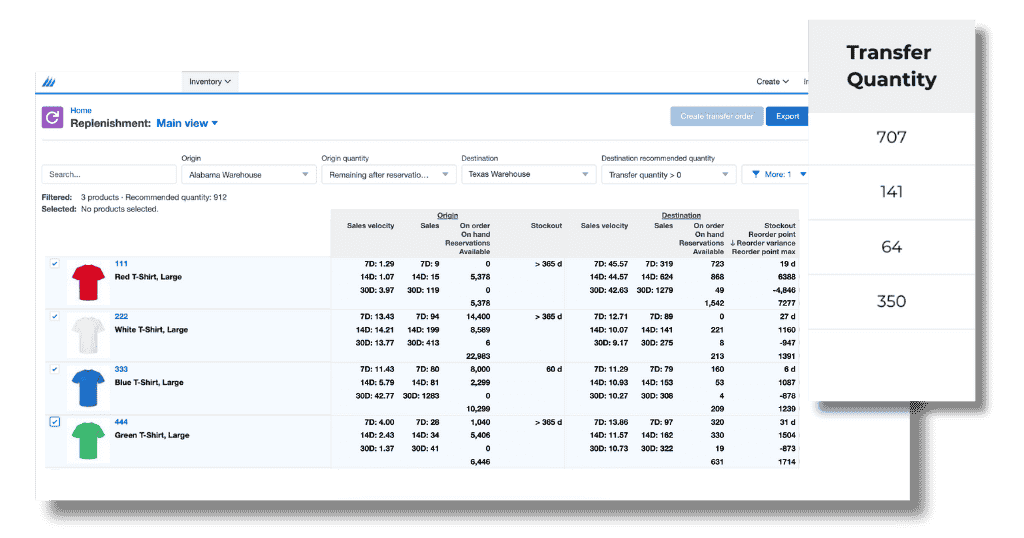

Seamless Multi-Warehouse Transfers & Inventory Tracking

Finale Inventory streamlines multi-warehouse management by providing a single, centralized platform for seamless inventory tracking and transfers across multiple locations. With transfer orders, businesses eliminate manual data entry, minimize errors, and ensure real-time accuracy as inventory updates automatically at both sending and receiving locations.

Bulk imports enable swift processing of large transfers, saving time and reducing overhead. Additionally, mobile barcode scanning simplifies and accelerates stock transfers between warehouses, retail stores, or fulfillment centers, further boosting efficiency and enhancing traceability.

Finale Inventory. The Ultimate Multi-Warehouse Inventory System.

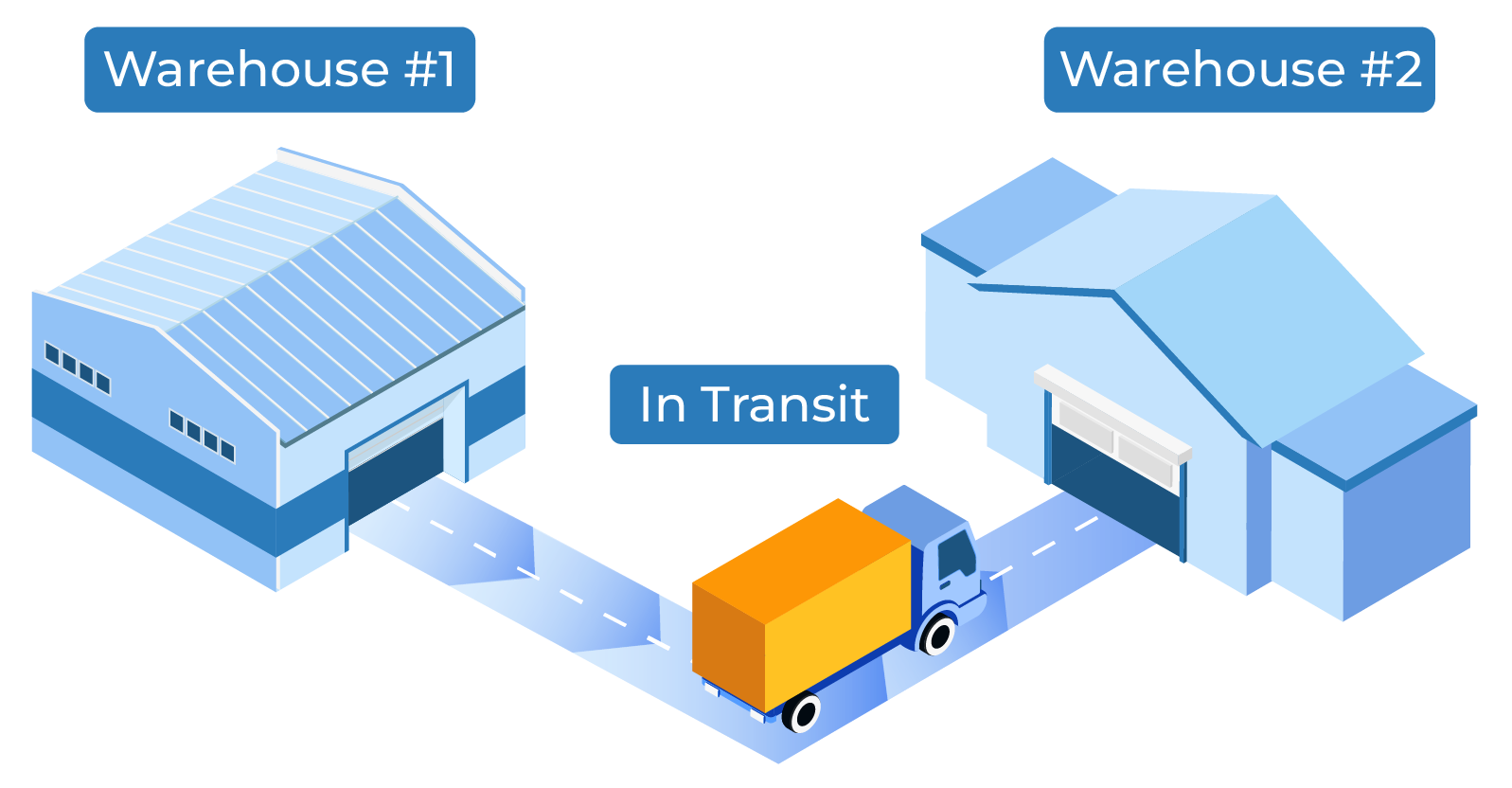

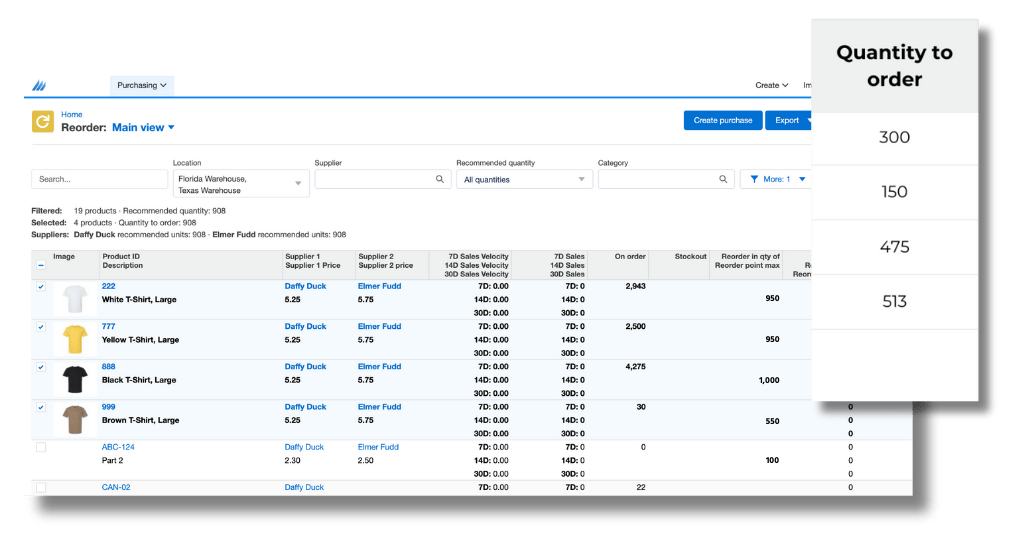

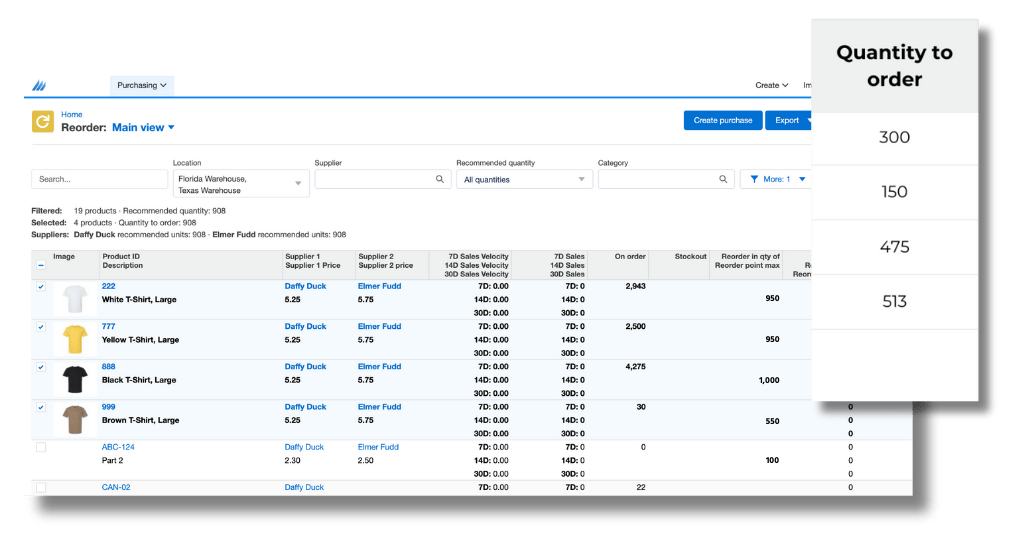

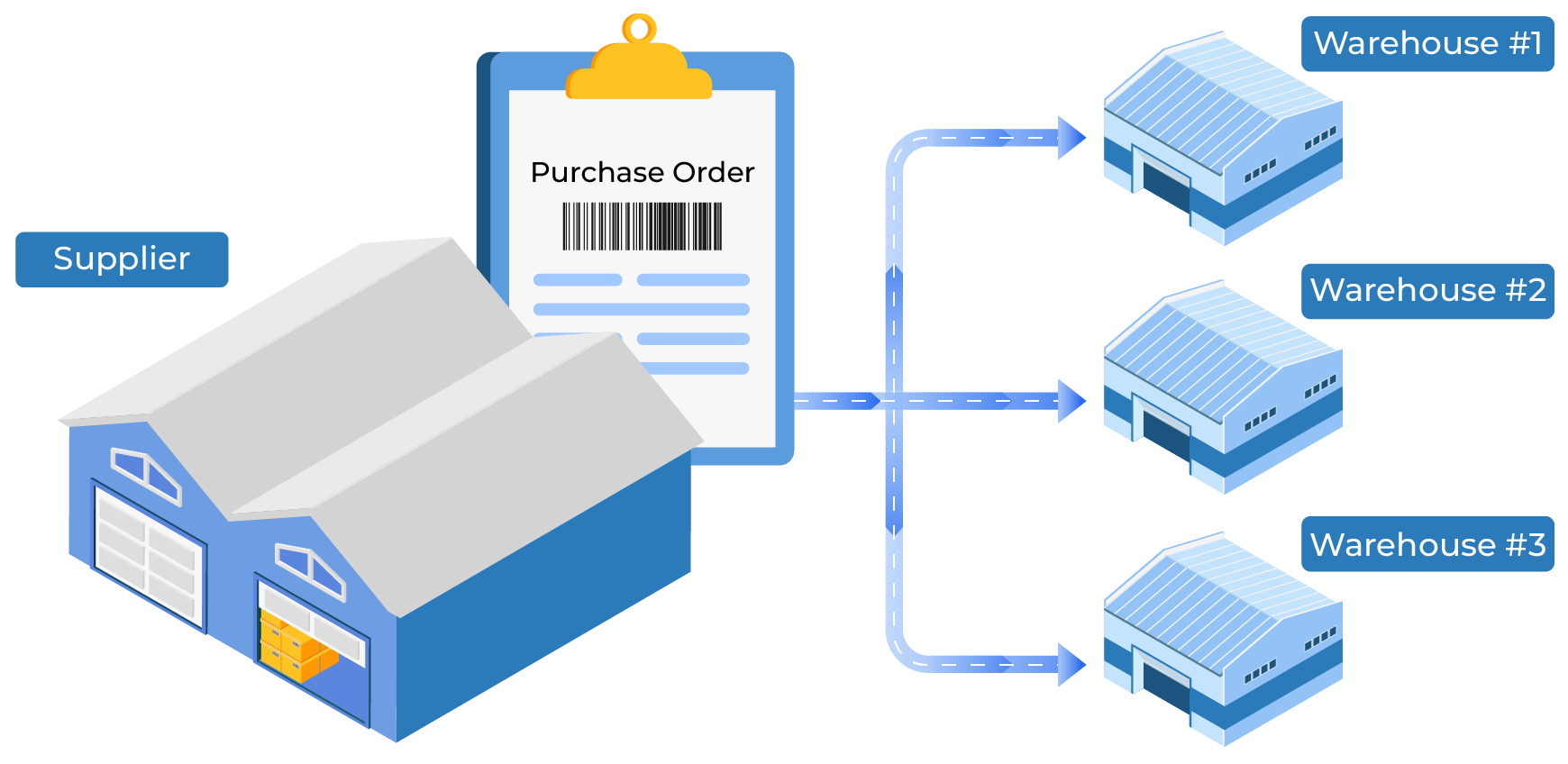

Automated Reordering & Replenishment Recommendations

Streamline reordering, replenishment, and sales tracking in one place: If you’re running multiple warehouses or brick-and-mortar stores, Finale makes it simple to reorder inventory with purchase orders and replenish stock by transferring items between locations, all from a single platform. Plus, it consolidates sales data across all locations, giving you a complete view of your inventory and performance.

The Finale reordering tools are location-specific so you can have separate reorder points per location to account for sales velocity per location or the preset minimum thresholds if using manual reorder points.

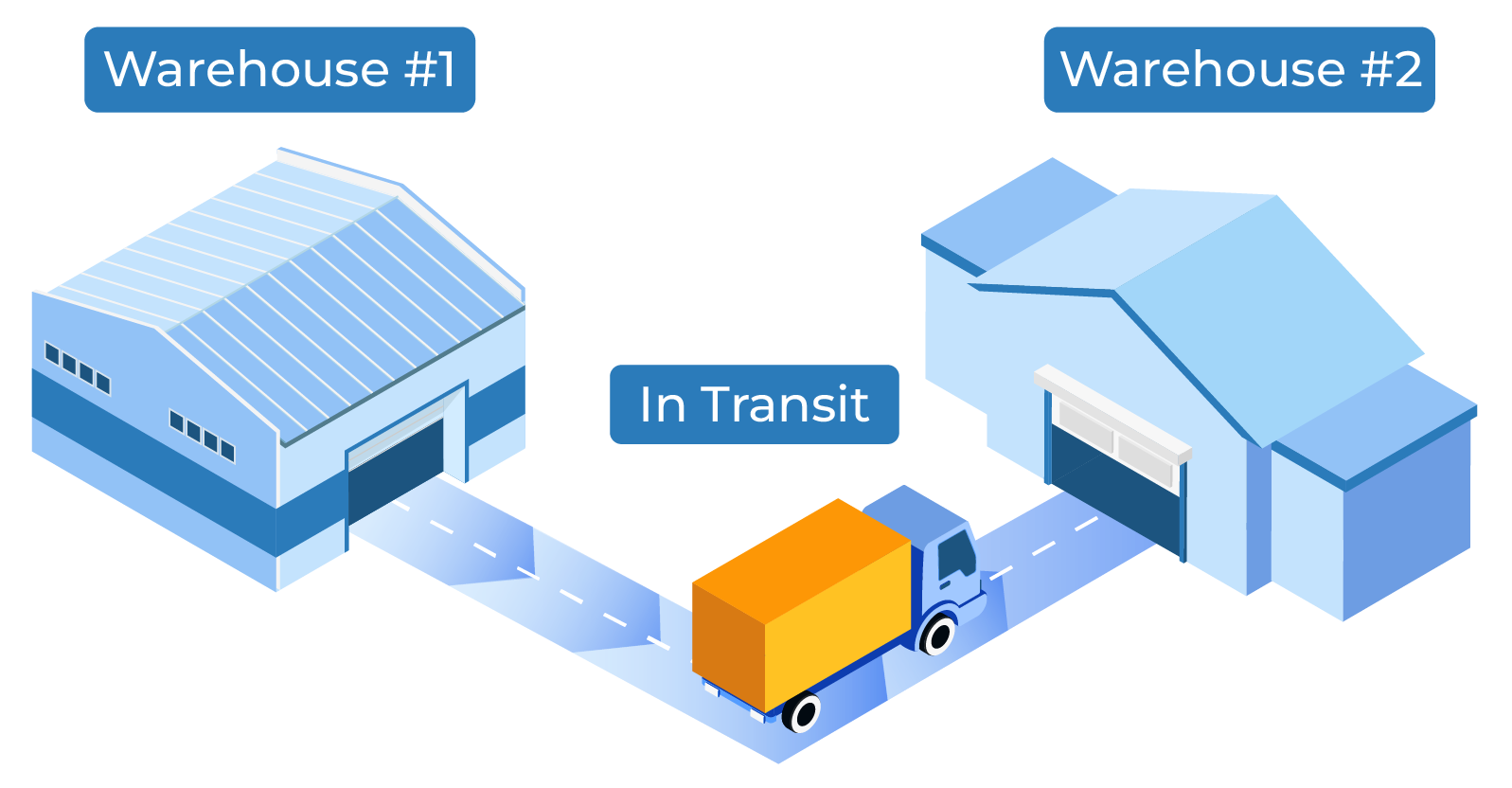

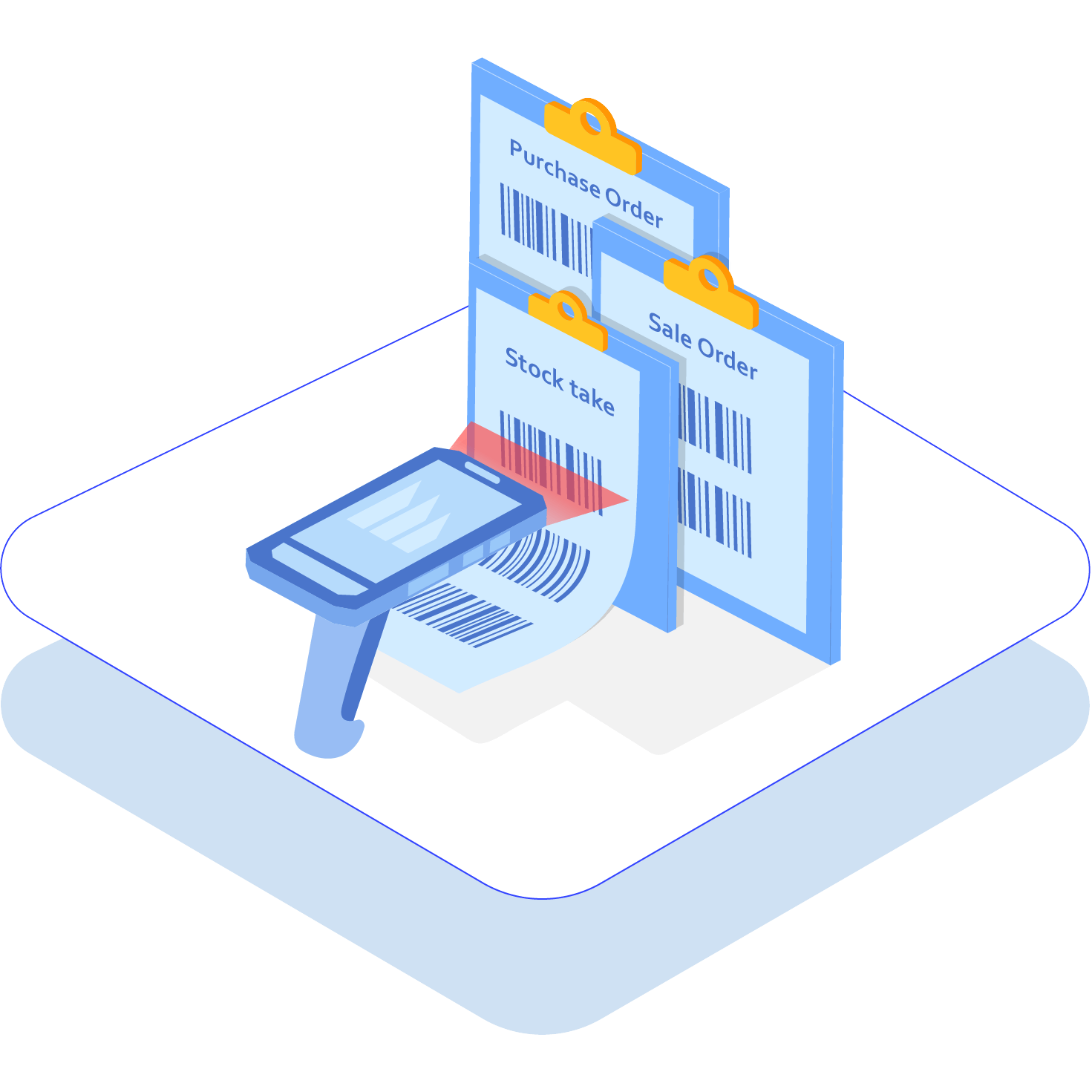

Eliminate Manual Errors with Automated Barcode Tracking

Finale's barcode scanning updates stock movements in real time, eliminating manual entry and reducing errors. Quickly track items across warehouses, stores, or fulfillment centers for accurate inventory counts and better visibility. With barcode scanning, you can instantly track items as they are received, sold, or transferred between locations.

One Hub for Ecommerce Sellers Using Multiple Fulfillment Centers

Finale Inventory is designed to track ecommerce stock across multiple fulfillment centers, perfect for sellers like on FBA.

Finale integrates with major ecommerce platforms and marketplaces, like Shopify, eBay, and Etsy, syncing inventory data in real-time. This ensures that stock levels are accurate across all fulfillment centers, preventing overstocking and stockouts. Finale lets you streamline replenishment between fulfillment centers—all from one centralized system. We keep your ecommerce operations running smoothly, no matter how many locations you're managing.

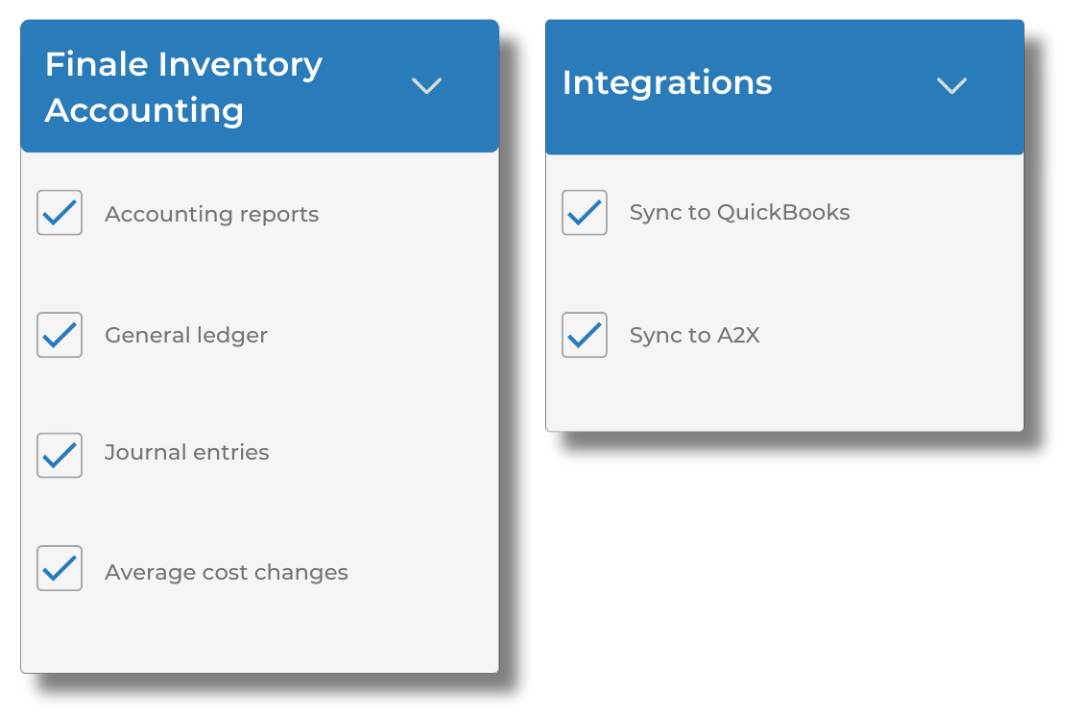

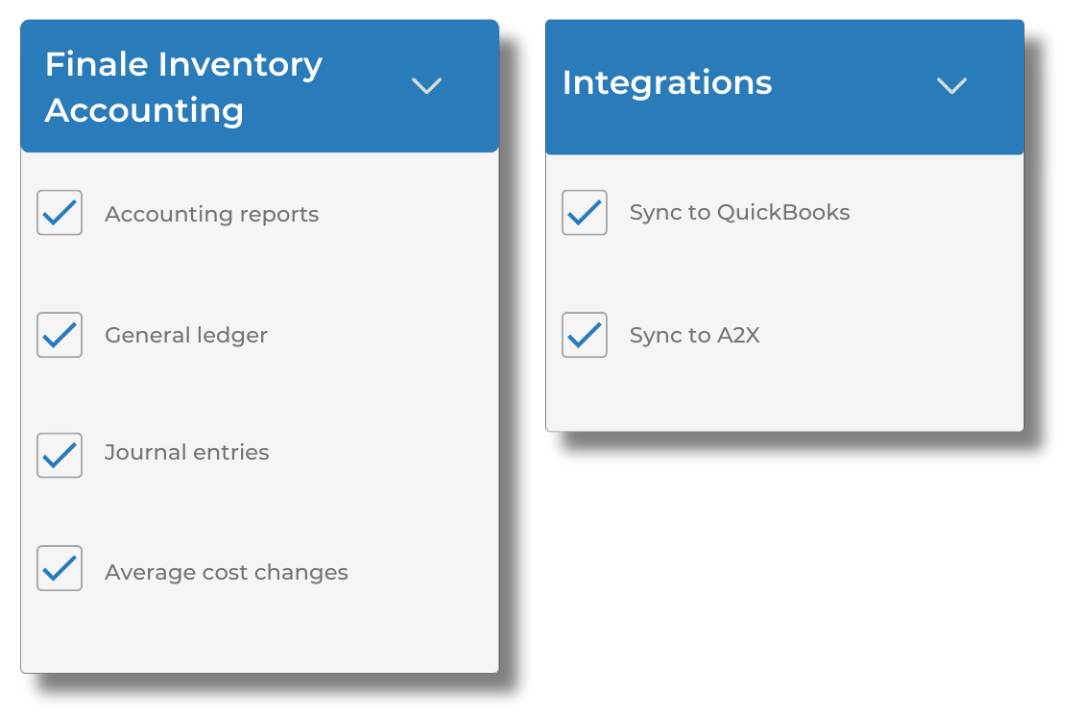

Easier Accounting For Multiple Warehouses

Finale Inventory simplifies inventory valuation for businesses with multiple warehouses. It centralizes purchase orders, sales orders, and stock movements, reducing manual bookkeeping and financial discrepancies. Gain real-time tracking, accurate COGS calculations, and better tax compliance. Easily integrate with QuickBooks Online or A2X for seamless financial management.

"The past few years we have expanded our warehouse and business to multiple locations... Finale staff was great to help us through all the steps of switching over... Even after we were set up and running, they maintain their relationship helping us use Finale to its full capacity, and always been there to answer questions."

Finale users can quickly create a transfer order to reserve inventory before any transfer fulfillment operations take place. This is especially important to ensure that you do not oversell your stock as you are putting together a shipment that needs to move between facilities.

By using transfer shipments, you can ensure that the stock is accurately tracked as it moves through the various states in Amazon.

Learn more about FBA transfers

Finale's reordering tool can be used for your FBA locations. Be sure to filter which FBA location you want the order to go to.

No! You have an unlimited number of locations and sublocations (bin names). This is even useful if you have a temporary storage unit, stock in containers, or pop-up shops. Create as many bin names as you need, no matter the naming convention.