If you are looking to implement multi-warehouse inventory management, you can use many strategies and tools to handle the logistics involved and save on expenses. One of the most essential tools you need is cloud-based multiple warehouse inventory control software like Finale Inventory.

Here are some of the most important things you need to know when managing inventory in multiple warehouses.

What Is Multiple Warehouse Inventory Software?

A multi-warehouse inventory management software system enables you to track inventory levels in different warehouses in real time. You’ll be able to manage orders for each of your warehouses from the same location.

The core capability of inventory software for multi-warehouse management is labeling stock in more than one location and sublocation within the app. You can view inventory levels at your New York warehouse and your California warehouse in one simple interface and decide whether to reorder from a supplier or transfer stock between locations. With sublocation capabilities, you can view quantities of a particular SKU within separate shelves, aisles or bins at each warehouse.

It also helps monitor the delivery of new stock to specific locations and optimize inventory and order fulfillment across your warehouse network. The system automatically chooses the closest warehouse to fulfill orders, so you can save the cost of shipping and meet customer demands quickly. When inventory at one location starts to dwindle, you can schedule a stock transfer from another warehouse so your quantities at both locations will be enough to meet local demand while you await a restock.

Some helpful features of multiple location inventory management software include:

- Barcoding capabilities: Once your inventory and team grow large enough to justify more than one warehouse facility, you’ll likely benefit from barcode inventory management, too. Barcode scanning speeds up operations by guiding workers through key warehouse operations such as receiving shipments and picking orders. Whenever a stock operation occurs, the barcode reader instantly logs it in your software so it’s immediately traceable and accessible.

- Intuitive stock transfers: With or without barcode scanning capabilities, multi-location warehouse management software should allow you to trace inventory that you move between warehouses. Workers at both locations should see that a transfer is scheduled or in progress and prepare appropriately.

- Inventory forecasting: Once your inventory becomes complex enough to require many warehouses, demand forecasting becomes even more useful. The right software will use a dynamic calculation based on your current sales, desired level of buffer stock and supplier lead times to recommend an exact reorder-by date for every item.

Benefits of Multi-Warehouse Inventory Management Software

With an efficient inventory management system, you can enjoy the full benefits of a distributed warehousing system and keep scaling up your operations as your business grows. Some of the advantages of a multi-warehouse inventory system include:

- Low labor and transport costs: With adequate stock levels of products in warehouses throughout your service area, you’ll be able to ship orders to the customer within the shortest time frame over the shortest distance. This reduces the cost of shipping and the labor required to move the goods to the customer.

- Backup for any unfortunate event: Sometimes a warehouse runs out of stock due to a natural disaster or logistics issue. Having multiple warehouses makes it easy to ship the product from another location without keeping your customers waiting.

- Exceptional customer service: When you run more than one warehouse, you can fulfill orders faster than your competitors who have just one. Customers will be more likely to spread the word about your excellent service and prompt delivery — which can increase sales.

- Faster delivery options: As soon as you have a delivery system that can fulfill orders rapidly, you can offer discounts and incentives to customers who want same-day or two-day delivery. This will encourage more customers to buy since they’ll enjoy the satisfaction of quick delivery.

- Centralized inventory management and better communication: By tracking stock across all your warehouses in one platform, you gain visibility over your operations. Workers at any location can view stock levels at other sites, and you can manage inventory with a bird’s eye view. If one location runs low while another is overstocked, you can schedule a transfer instead of reordering from a supplier. This measure prevents further overstocking and helps you redistribute your excess merchandise more effectively.

How to Manage Multiple Warehouse’s Inventory

To manage your inventory in different warehouses, you’ll need to do the following:

1. Choose the Right Locations

Select warehouse sites that help you reduce costs and fulfill orders faster. Warehouses in strategic areas close to your customer base help you save time and transportation costs. However, you might also factor in the local real estate market and location-specific costs like taxes and electricity to find the best location.

2. Use an Efficient Warehouse Layout

Arrange the shelves, pallets and pathways so that inventory is logically organized and can be easily moved into and out of the warehouse.

3. Use the Best Tools to Keep Inventory Synchronized Across Warehouses

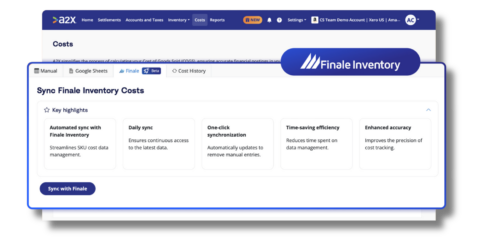

Use stock management software like Finale Inventory. This cloud-based solution automates and speeds up inventory management processes, including:

- Monitoring stock levels in real time by location.

- Moving products between warehouses.

- Connecting your accounting and e-commerce website to your inventory data.

- Creating and tracking purchase orders.

- Providing robust analytics and reports.

- Forecasting and calculating order quantities for each product.

Discover if Finale Inventory Is the Right Fit for Your Multiple Warehouse Management

Finale Inventory is a proven multiple warehouse management system with many high ratings and positive reviews online.

Our tools combine multiple warehouse management software with sophisticated inventory tracking to give you a complete system to stay organized and grow your business. With the ability to manage stock audits, lot and serial numbers, invoices and shipping documents across multiple locations, it’s the solution you need for multi-site inventory management. Our flexible, scalable architecture supports up to 300 users, 1.5 million products and 1.5 million SKUs, so it can grow as large as your operation does.

To discover the power of this software, sign up for your 14-day free trial or request a live demo today. You can also call us at 888-792-8891. We’re available 24/7 to answer your questions.