Warehouse Inventory Management: The Ultimate Guide to Follow

When running a business, the most important thing you can do to keep your business afloat and successful is to practice proper warehouse inventory management. This is essential no matter the size of your business, and it’s especially imperative the more inventory you have to keep track of and coordinate.

When your warehouse inventory is managed poorly, it can lead to problems that can truly break your business down from the inside out. Unhappy customers, wrong shipments, misplaced items and more are just some of the concerns poor inventory management can lead to, putting your business in a precarious position.

If you want to learn how to maintain inventory in a way that keeps customers happy and using your products or services, helps your business grow and brings in revenue, then you’re in the right place. This Ultimate Guide to Warehouse Inventory Management will help you do everything you need to keep up with high demand, changing trends, new technology and a growing company.

Understanding the Importance of Warehouse Inventory Management

Whether your business exists online, in brick and mortar stores or both, you must know that the secret to success lies in warehouse inventory management. No matter where you are in your business journey — whether creating a new business or managing a seasoned establishment — warehouse inventory management is the first and most critical step to success.

In the simplest terms, warehouse inventory management refers to keeping all your items and products organized while awaiting shipment and well stocked so customers can buy them. It requires knowing how to organize inventory in a warehouse alongside constant monitoring to ensure a steady supply without over- or understocking.

It is estimated that $1.1 trillion of companies’ capital is tied up in inventory, accounts receivable and accounts payable. That means that a huge chunk of your funds are bound to this single aspect of your business. With such a large amount of money on the line, it makes no sense that over 40% of businesses either use outdated inventory tracking methods like spreadsheets, manual tracking methods like pen and paper, or no method at all.

A company may not keep good track of its inventory for many reasons. They may not have enough staff to do so. Their inventory may be too large to contain, or they may be too behind due to poor management practices that they can’t catch up. Whatever the case is, it is not wise to continue without some warehouse inventory management system in place.

Efficient inventory management offers many advantages, such as:

- Cost savings: Inventory is a significant investment. It costs money to acquire the physical products and transport them to your warehouse, as well as to store them in your facility. By only purchasing as much stock as you need to meet demand and moving it quickly, you reduce your purchasing and holding costs. With less money tied up in non-liquid assets, your business can dedicate more resources toward growth.

- Boosted sales opportunities: While ordering less inventory results in cost savings, being understocked can be just as costly. By accurately predicting the amount of stock to meet demand and reordering at the right time to prevent from going out of stock, you can take advantage of more sales opportunities.

- Time savings: Having the right amount of stock available at the right times saves you time by allowing you to keep to a predictable fulfillment schedule. Having well-organized merchandise saves time by reducing the time required to find items. Meanwhile, using software to aid in stock management operations saves you even more time by automating many time-consuming manual processes.

- Improved customer satisfaction: When your most popular items are always well-stocked and ready to ship, customers get to enjoy their shopping experience. They can add items to their carts without out-of-stock notices impeding their buyer’s journeys. When they place an order, they’ll soon be greeted with a notification that their shipment is on its way.

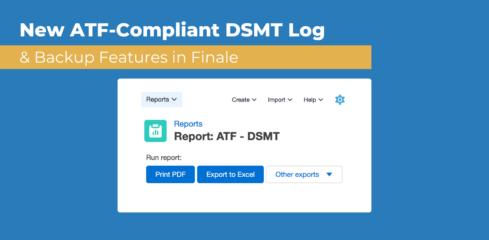

- Regulatory compliance: Certain businesses face strict inventory regulations, such as the fireworks industry. When misplacing merchandise is not an option, an inventory management system that runs like a well-oiled machine helps you exceed regulatory standards.

Remember that not just any system will do — as you continue through our ultimate guide, we’ll provide some options perfect for your business warehouse needs.

Upgrade: Why You Should Be Using Inventory Management Software

Are you one of the businesses using spreadsheets in Excel or pen and paper to keep track of your inventory? If you are, you need to upgrade your stock management system as soon as you possibly can. These methods are outdated and have a considerable margin for error, making it unwise to continue with them. Proper warehouse management in today’s digital era demands the use of a dedicated inventory management software system.

Software systems make inventory management easier in so many ways that you’ll wonder how you ever did business without one. You’ll track your warehouse inventory in an organized fashion and have the capability to:

- Perform full audits whenever you need or want to.

- Draw up invoices and other customizable documents.

- Automatically reorder products and predict future inventory demands.

- Keep sales records up to date.

- Track inventory across warehouses.

- Monitor trends in supply and demand.

- Manage everything across multiple devices.

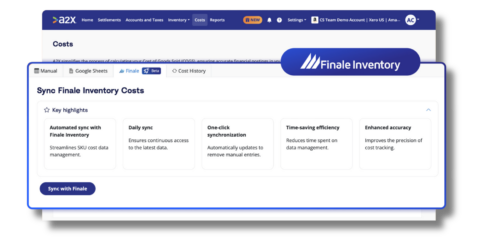

You and your stock control team also get easy integrations with other business tools and access from anywhere, whether it’s your phone, laptop or tablet.

Most software systems are cloud-based as well, which means that once you save your data, it will always exist online where you can access it and back it up. With the help of the right technology, you’ll have complete visibility over the products in your warehouses. That way, they’re always ready and on hand for shipment. This is made even easier with the addition of advanced inventory control features like barcode scanners and serialized product tracking.

Barcode Labels and Scanners

Part of your warehouse management upgrade should be the inclusion of barcode labeling and barcode scanning devices with corresponding software. When you assign a specific barcode to each item, you always know where it is in your warehouse because it gets scanned whenever it moves. It makes the product easier to track when en route to the customer and keeps items from getting lost or misplaced in the shuffle of everyday business.

Barcode-enabled inventory management is one of the most powerful warehouse management tools at your disposal. It streamlines stock operations such as:

- Receiving shipments: When supplier shipments arrive in your warehouse, workers can simply unpack the boxes and scan what’s inside to add it to your inventory. If you prefer using your own barcodes, workers can create and print labels on the fly as they’re marking shipments received.

- Picking orders: Barcode scanners offer discrete and batch order picking settings, allowing you to use the picking methods that work best for your workflows. Whatever picking method you choose, the scanner guides workers through the warehouse in the most efficient route and tells them what items to scan, which saves time and reduces picking errors.

- Conducting stock takes: When it’s time to do a physical count of your inventory, workers can use a barcode scanner to quickly check your software’s records against what’s actually in the warehouse. The scanner guides the process to make it more efficient and quickly identify discrepancies.

- Transferring stock: When moving stock between warehouses or from one sublocation to another, workers can use a barcode reader to quickly log the transaction in your inventory software.

This is especially important considering how detrimental it is when items are lost or misplaced in the warehouse and when the customer is waiting for them. Slow delivery and lost items can turn a customer sour and cause them to shop elsewhere. With this in mind, including a barcode scanner is an excellent decision because it gives you an advantage over your growing stock. Everything stays in order and well accounted for — which saves you money — and customers are more satisfied — which can only bring in more money.

Lot IDs and Serial Numbers and Why You Need Them

Many businesses use lots and serial numbers for enhanced security and other benefits when tracking products through the receiving and sales process. While similar, lots and serial numbers have differences that make them useful for different business needs. Both are assigned to products during the production process to keep track of products more granularly and improve overall traceability. This is really where the similarities end.

Lot ID number tracking, for example, is used for certain items like food, fireworks and textiles like yarn and fabrics. Lots correspond to a specific number of products assigned to a group of items with shared properties, like those manufactured in the same batch on the same shift. Even if the items are not identical, they share certain similarities that warrant grouping them together. Lot numbers provide an extra amount of accuracy for tracking manufactured dates, the specific dyes or ingredients used, expiration dates and more.

On the other hand, serial numbers are assigned to individual products that may be different for iterations of the same product. This means that every single product has a unique number, allowing that item to be tracked from packaging, shipment, delivery and arrival. For example, while two cars may be the same make and model, they might have different optional features, colors and upholstery.

Serial numbers are often reserved for products like cars, appliances and other electronics. Consider your laptop — it is one of many of the same model and has its own unique serial number that keeps track of it should it get lost, damaged or otherwise compromised. This serial number beefs up traceability quite a bit, giving your products extra security when they’re in your possession and when they move on to the customer.

Of course, lots and serial numbers only work with barcode scanners, meaning that without this element, you’ll have a hard time keeping track of your own inventory. This all circles back to your upgrade, making your inventory management process smarter, sharper and easier.

Update Your Warehouse Management With Finale Inventory

Business management is always an adventure, so you want to embark with the right tools. When you get rid of old practices like Excel spreadsheets and manual inventory tracking and bring in warehouse inventory management software, it can really transform your business into something stronger and more efficient. While simple, we hope this streamlined warehouse management guide provides you with the information you need to make your business epitomize efficiency and success. Remember, well-managed warehouse inventory results in a thriving business every time.

Finale Inventory offers powerful inventory and warehouse management software that’s flexible and scalable to meet any business need. Besides our robust turnkey barcode management solution and our intuitive serial number and lot ID tracking capabilities, we offer many features that will make your warehouse more efficient. We have everything you need to streamline your operations and organize your inventory — from inventory reorder forecasting and purchase order management to multilocation support and stock auditing.

Check out Finale Inventory in action with a live real-time demo or a free 14-day trial today.