Master Your Inventory Cycle Count by Practicing These 7 Steps

Every business owner should know that when inventory is under control and well-managed, things are going smoothly. Whether a business is a startup, a small or medium organization or a large conglomerate, inventory should be a top priority.

No matter how you run your business, you can’t get around the importance of proper inventory management and maintenance. One way to ensure a well-managed inventory is through inventory cycle counts. When performing cycle counts, you’re ensuring your stock stays organized at all times because, as the name suggests, this practice comes in cycles as well. Not entirely sure how to execute a successful cycle count? You’re in luck. By practicing the following seven steps, you can learn how to master your inventory cycle count.

What Is a Cycle Count?

Before we get into how you can master your inventory cycle count, first, let’s break down what cycle counting actually is and why it matters for your business. In short, an inventory cycle count is a process that requires you to count a small amount of your inventory at a specific time, usually on a set day, without handling your entire stock in one go. It’s a type of inventory auditing method that ensures your inventory is accurate and up to date at all times.

The purpose of cycle counting is to apply statistical analysis to understand your inventory. You’ll use statistical sampling to choose which items to count, helping you estimate how accurate your inventory records are without having to tally every item all at once. For example, if the SKUs you counted this month all come in at roughly 10% below the count in your records, you can assume the rest of your inventory probably also experienced 10% shrinkage.

In essence, an inventory cycle count is pretty similar to the physical inventory counts you’ve done, except it does so with a different approach. When you take a physical inventory count, you count 100% of your inventory at once. It may take several weeks of undivided attention, and many warehouses have to halt other operations to keep up.

Instead of doing physical counts, you can delegate small portions of your inventory to certain employees on a predetermined schedule. This allows you to go over all of your stock a little at a time in a focused manner, lowering the risk for inaccuracies.

Generally, a cycle count can take anywhere from a day or week to several months, depending on the size of your inventory. You can schedule them on an ongoing basis so your inventory is always well accounted for. Though it can be a lengthy process, performing inventory cycle counts instead of one large physical audit can actually save you a lot of time, benefiting your business. So how can you get started with your inventory cycle count? Certain practices can make this simple method even easier.

Why Is Cycle Counting Important?

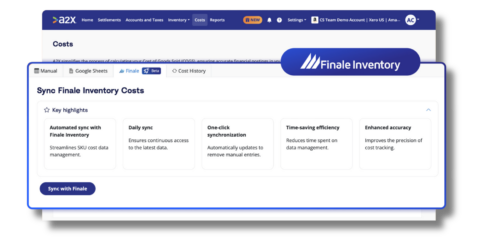

Cycle counting is a way to verify the inventory you have in stock and reset any inaccuracies. For the most part, you may be going by your sales and reorder records to track what’s in your warehouse. If you use inventory management software such as Finale Inventory, your quantities update in real time as sales, reorders and shipments occur.

However, over time, manual and automated inventory tracking can both lose accuracy. This is because you can’t always account for shrinkage and the occasional typo in data entry. If any of the numbers in your system are incorrect, your cycle count is a chance to recalibrate.

In your warehouse, some inventory may become damaged, lost or stolen. Your inventory tracking system will probably count these items as in-stock, even though you cannot sell them. Besides updating your system to reflect missing inventory, cycle counting gives you a chance to inspect and remove any merchandise unfit to sell.

Regular cycle counts can also help you notice which products or areas are most susceptible to shrinkage. With this data, you can get to the bottom of employee theft or facility issues that may cause product damage.

Steps for Warehouse Cycle Counting

There are three basic types of warehouse cycle counting, which all require slightly different methods. Here are the steps for cycle counting using each technique.

How to Perform ABC Cycle Counting

As one of the most popular types of cycle counting, the ABC method counts items more or less frequently based on their importance to the business. It follows three steps:

- Assign your inventory to classes: Your A inventory items are your most profitable merchandise subject to the biggest inventory issues. B items are high-value items with fewer inventory concerns, alongside your less valuable merchandise with significant inventory issues. Finally, C products are those with low value that also have relatively few inventory concerns.

- Set a cycle count frequency: Next you can determine how often to count your A, B and C SKUs, counting A products most frequently.

- Randomly select items to count based on frequency: Count a few SKUs chosen through random selection every week. Once an SKU is counted for the last time as required by your desired frequency, remove it from your selection pool for the rest of the cycle.

How to Perform Control Group Cycle Counting

Control group cycle counting tests and fine-tunes your cycle counting. It follows four steps:

- Select a few products in your inventory and count them.

- Repeat your counts several times over a short period.

- Examine your numbers and identify errors in your counting techniques.

- Make changes until your cycle counting method is ready to roll out across your entire inventory.

How to Perform Random Sample Cycle Counting

In this technique, SKUs are randomly selected for cycle counting on a set schedule, such as every day or once a week. It uses one of two methods:

- Constant population counting: After randomly selecting and cycle counting SKUs, return them to your selection pool.

- Diminished population counting: Once items have been selected and cycle counted, remove them from the drawing until you count every SKU.

7 Tips to Master Your Inventory Cycle Count

Check out these seven steps that will help you perform a fast, accurate inventory cycle count every time you do one.

1. Do a Cycle Count at Least Once a Year

First things first — you’ve got to have a schedule in place to ensure your inventory is always covered. One great practice for a successful cycle count is to get one done at least once a year. This doesn’t mean that you leave the entire project for a single day or week each year. Rather, it means that you have cycled through your entire inventory by the end of the year at least once, and more than one cycle is best for optimal results.

Most businesses find that the best time for a cycle count is once every 12 or 13 weeks. On this schedule, you can conduct an inventory cycle count four times in a year, or quarterly. If you do a continuous inventory cycle count, you divide your inventory into smaller portions and parse through just one section before moving onto the next.

With this pattern, your inventory will be organized all year round, making things easier for you and improving both business and customer relationships.

2. Prepare Your Warehouse Before the Cycle Count

This step is best done when your business is new and your warehouse or warehouses are just getting set up. Of course, if you have a more established business with warehouses that are already full or cluttered, this step is still important and doable. Before you do a cycle count, you should make sure that your warehouse is clean and de-cluttered.

First, go through it all and get rid of dead inventory or inventory that is no longer profitable. It takes up space that you could use for live inventory, and racks up carrying costs. A great way to determine what is dead inventory is to check sales for the last few quarters and see which products aren’t selling enough or at all. Then locate these products in your warehouse and put them on clearance or offer a promotion to move them out quickly and efficiently.

Locating obscure, dead inventory can be time-consuming, so you may want to invest in some barcode scanning software solutions, like those offered by Finale Inventory. With a barcode scanner, you can locate all products so you can grab them and get them out of the way. Scanners will also be useful during the actual cycle count!

Next, prepare your employees for a coming cycle count. Designate certain products to assigned teams, explain what you expect during a cycle count clearly, and provide them with all tools and information necessary to guarantee a successful count.

3. Focus on One Category at a Time

When you begin your cycle count, focus on just one category of your inventory at a time. For example, if you sell pet products such as foods, toys, clothes, apparatuses and accessories, you could divide your categories as follows:

- 1st Quarter: Cycle count only food items — i.e. kibble, treats, canned foods, etc.

- 2nd Quarter: Cycle count only toys and apparatuses — i.e. cat towers, scratching posts, hamster homes and habitats, etc.

- 3rd Quarter: Cycle count only clothing.

- 4th Quarter: Cycle count only accessories — i.e. collars, nametags, leashes, harnesses, etc.

By dividing inventory into categories, you can go over everything without running the risk of missing something, fudged numbers, or other inaccuracies. A barcode system will also be helpful here as you can locate all similar items within the warehouse and group them together for an even easier cycle count.

4. Set Up a Pattern to Get Through Your Whole Inventory

To get even more organized, consider setting up a pattern to get through your whole inventory. Dividing inventory into categories is an excellent start, but take things a step further with a pattern. This can be anything from going alphabetically through products, moving through certain parts of the warehouse, or working on certain warehouses for businesses with larger inventories.

5. Keep Your Inventory Organized Between Cycles

When not doing a cycle count, you must keep your inventory organized at all times to ensure accuracy and ease. If inventory is messy, it can make cycle counts nearly impossible, taking up time and effort that could be used for other business functions. With the help of software solutions like Finale Inventory’s cloud-based inventory management software, you can make sure your inventory is always organized, even during the offseason.

It’s helpful to set routines for warehouse upkeep. Have a logical storage system that helps team members easily decide where to put new inventory. Track items by location in your stock control software so they’re easy to find. Also, clean out unusable inventory and clutter regularly so important items remain visible.

6. Sync Your Budget With Your Cycle Count

When using inventory cycle counts, be sure to budget for growth. Your financial plan will change as you gain more customers and your business and inventory expand. Cycle counting is even more important the more inventory you have — because there’s much more to keep track of — so you want to make sure you make room in your budget for the future.

7. Always Have a Plan

Finally, no matter how you do your inventory cycle count, make sure you always have a plan. When running a business and keeping inventory organized, things can get crazy at the drop of a hat. Instead of floundering around, have a plan in place to take care of your quarterly routine so you can perform cycle counts accurately and on time. To make things even smoother, have a plan B, C and D just in case!

Change the Way You Cycle Count With Finale Inventory

As you run your business, never forget the importance of an organized inventory. If you ever need help with inventory management or inventory management practices like cycle counts, give Finale Inventory a try. You can begin a free trial today and learn about all Finale has to offer — from barcode scanners and warehouse management software to integrations and inventory tracking.

Our barcode scanner solutions feature an intuitive cycle counting setting, which will guide warehouse workers through the cycle counting process to ensure fewer errors and make any discrepancies immediately apparent. To see our barcode scanning software in action, sign up for a demo or start your 14-day trial today.