Inventory Aging Report: What It Is, Why It Matters & How to Use It

Inventory aging report insights turn dusty shelves into cash flow wins. Discover how this practical guide explains the buckets, formulas, and warning signs that reveal where capital is trapped, how long stock should stay, and which marketing or purchasing moves unlock growth. Whether you manage Amazon FBA, a DTC warehouse, or multiple 3PLs, you’ll learn proactive strategies that boost turnover and prevent costly deadstock losses.

How to Calculate Average Inventory: Formula & Step-by-Step Guide

How to calculate average inventory is the lifeline smart eCommerce sellers use to unlock cash flow, avoid stockouts, and slash costly overstocks. This concise guide clarifies the formula, shows you where to pull accurate beginning and ending balances, and reveals when seasonal adjustments or automation tools beat spreadsheets. Real retail and Amazon FBA examples turn dry math into actionable insight you can apply today quickly.

Forecasting in Excel: A Practical Guide (with Inventory Examples)

forecasting in excel arms merchants with a step-by-step roadmap to convert raw sales rows into clear-cut demand signals and profit-saving reorder points. Discover smart data prep, moving averages, weighted smoothing, FORECAST.ETS, and the Forecast Sheet wizard; then validate, visualize, and refine accuracy. You’ll also learn the warning signs that spreadsheets are stalling growth and how to shift smoothly toward automated inventory systems when scale demands.

Excess Inventory: Causes, Costs & How to Manage Overstock

Excess inventory can strangle cash flow, but our in-depth guide shows multichannel sellers how to spot surplus early, calculate true carrying costs, and apply barcode-driven forecasting to keep stock lean. Discover KPI dashboards, ABC targeting, flexible MOQ tips, and smart liquidation plays for Amazon, Shopify, FBA, 3PL, and QuickBooks operations. Read on to convert dormant goods into growth fuel without risking service levels or reputation.

Economic Order Quantity (EOQ): Optimize Your Order Size

Economic order quantity is your blueprint for stress-free inventory control, showing precisely when and how much to reorder to cut costs, avoid stockouts, and keep cash flowing. This article unpacks the classic EOQ math, translates it into easy examples, and tackles real hurdles like FBA caps, supplier MOQs, and seasonal swings, giving multichannel sellers a clear, actionable roadmap to smarter purchasing decisions that drive profit.

Demand Planning Software: Mastering Forecasts for Optimal Inventory

demand planning software is the vital link between guesswork and smart inventory control. This guide covers forecasting basics, key features, AI advances, selection tips, and an 8-week rollout that moves you from spreadsheets to streamlined purchasing. Learn how SMBs trim stockouts, cut carrying costs, and free working capital while keeping customers happy across every channel without ERP complexity or steep learning curves along the way.

Demand Planner: What the Role Is, Skills & Software Tools

Demand planner expertise is the missing link between sales ambition and stocked shelves. Dive into this resource to see how sharp forecasting, clear cross-team dialogue, and cloud software turn raw data into lean inventory, higher margins, and fewer stockouts. Learn core skills, KPIs, and tech upgrades—like moving beyond Excel to integrated Amazon FBA and ERP connections—that keep growing brands resilient in today’s volatile markets everywhere.

Demand Forecasting Models: A Guide to Types & Techniques

demand forecasting models sit at the heart of inventory strategy, and this guide unpacks the time-series, causal, qualitative, and AI techniques every multichannel seller must know. Discover how clean barcode data, accurate lead times, and actionable KPIs turn predictions into profit, reduce stock-outs, and free working capital. Read on to choose, measure, and operationalize the right method for your business with confidence and measurable ROI.

Days Sales in Inventory (DSI): Formula, Calculation & Analysis

Days sales in inventory offers ecommerce sellers a rapid, cash-flow snapshot, showing how long stock lingers before selling and guiding smarter replenishment. This practical guide clarifies the formula, supplies step-by-step math, benchmarks, and real-world examples, then delivers proven tactics like demand forecasting, ABC analysis, lead-time cuts, and barcode accuracy to slash carrying costs, avoid stockouts, and unlock growth for fast-growing multichannel brands worldwide right now.

Bullwhip Effect: What It Is & How It Distorts Supply Chains

Bullwhip effect warning: a slight TikTok buzz can swell into supplier delays, rush freight bills, and cash tied up in dusty stock. This guide reveals the culprits—forecast swings, order batching, price jolts, shortage gaming—and shows how POS sharing, barcode accuracy, lean promotions, and shorter lead times dampen demand noise, protect ROI, and keep Amazon FBA, 3PL, and shop shelves reliably stocked year-round without ERP overhauls.

AI Inventory Management: The Future of Smart Stock Control

AI inventory management gives online retailers clear stock visibility and predictive power. Learn how algorithms curb stockouts, cut carrying costs, and autoreplenish Amazon, Shopify, and warehouse shelves. The guide details key tech, ROI wins, pitfalls, and a five-step rollout, and shows why Finale Inventory delivers the clean data backbone future-ready operations need for reliable growth. Plus practical tips to start your own AI journey today.

ABC Analysis: Prioritize Your Inventory Management

ABC analysis shows how 20% of your products often drive 80% of profits, and this guide explains the steps, pitfalls, and tech tools to harness that insight. Learn to rank SKUs, tailor reorder rules, automate cycle counts, and free cash tied up in slow movers. Whether you’re scaling e-commerce channels or taming a crowded warehouse, get the practical roadmap to smarter, leaner inventory control today.

Inventory Planning Software: Complete Guide to Smart Stock Management

Inventory planning software replaces fragile spreadsheets with data-driven clarity. This article shows AI forecasting, auto reorder points, barcode checks, and multi-site moves that cut stockouts and free cash. Get ROI data, vendor tips, and a four-step rollout plan that arms growing sellers to scale surely while trimming costs and pleasing customers across retail and online channels with speed, insight, and ease for lasting profit growth.

Fishbowl vs Finale: Inventory Management System Review and Comparison

Choosing the right inventory management system can make or break your operations, especially if you’re selling across multiple channels. Two popular options in the market are Fishbowl and Finale Inventory, each offering distinct capabilities for inventory control, warehouse workflows, and order processing. In this comparison of Fishbowl vs Finale Inventory, we’ll break down the strengths…

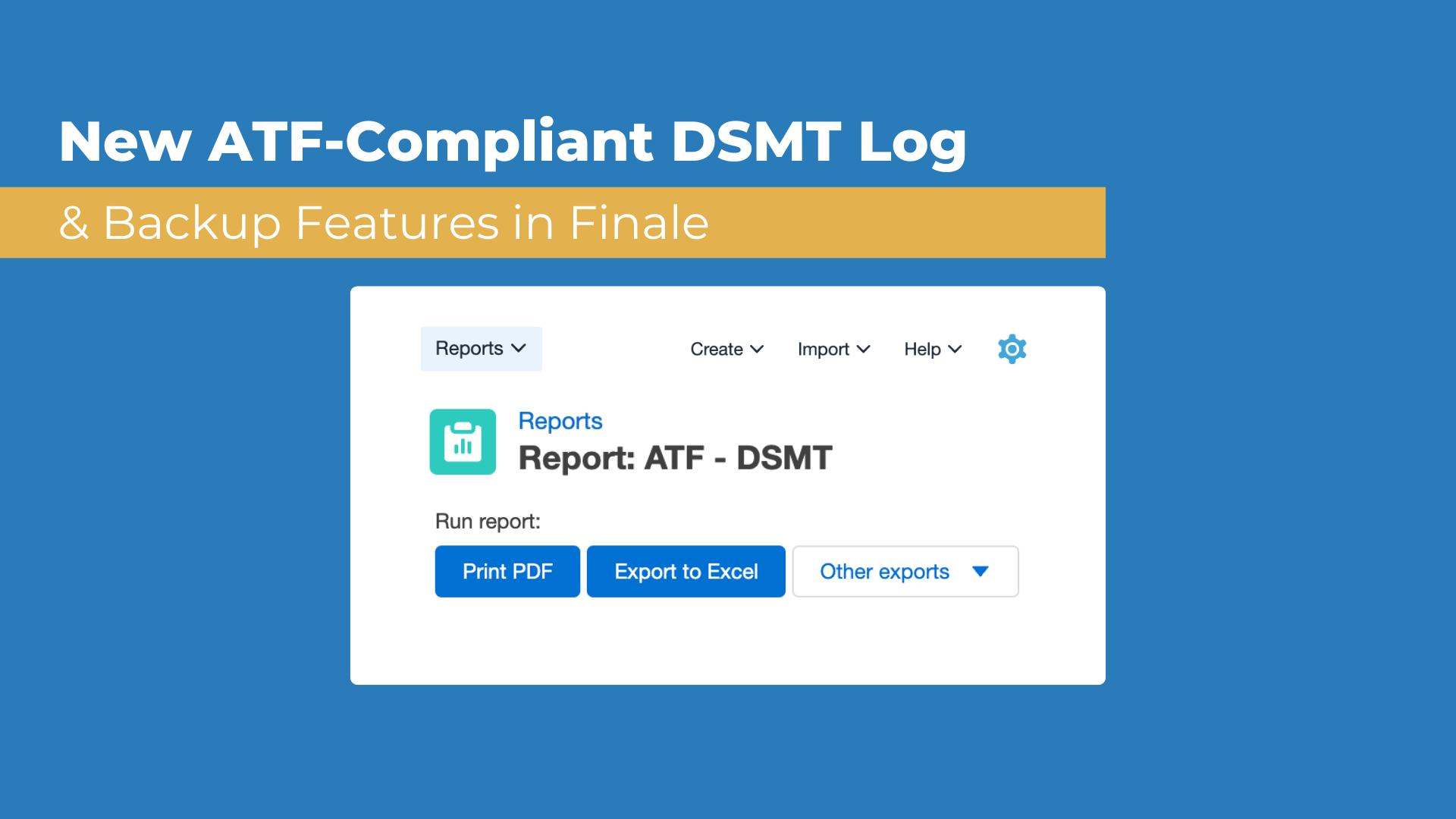

New ATF-Compliant DSMT Log & Backup Features in Finale Inventory

We are excited to introduce new features in Finale Inventory that ensure your compliance with the latest ATF Ruling 2023-1, which mandates stricter requirements for maintaining electronic records for explosives. Meet the ATF Compliance Requirements with Finale To support Federal Explosives Licensees and Permit Holders (FEL/Ps) in meeting 27 CFR Part 555, Subpart G, we’ve…

Chapter 11: The Fast, Slow and Non-Moving (FSN) Method

Fast, slow and nonmoving (FSN) inventory analysis is often used with ABC analysis to help inventory managers prioritize their inventory control techniques and resources. Fast-moving inventory may require more attention than slow-moving inventory, just as high-value products may require more attention than low-value stock. By first prioritizing how you will dedicate your attention and resources, you can…

Chapter 10: The Economic Order Quantity (EOQ) Method

When determining a reordering schedule, you can often save warehousing space by reordering more often in smaller quantities. However, reordering more often leads to higher logistics costs while saving on storage costs. Increasing storage costs will likewise lower logistics costs. The economic order quantity (EOQ) formula helps you balance these two costs to find the…

Chapter 9: Backordering

Another one of the essential inventory management techniques in operations management is backordering. What Is Backordering? Backordering occurs when your company decides to accept orders and receive payments for products that are out of stock. Essentially, this means you order a product only after a customer places an order for it. Though backordering can be financially beneficial,…