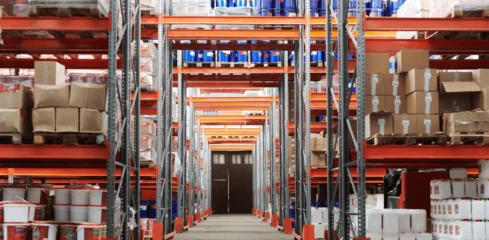

Mastering Warehouse Labeling for Clear Inventory Control

Warehouse labeling can seem like a tedious aspect of inventory control, but it can have a huge impact on your warehouse operations. It’s the difference between hunting for an item and wondering if it’s even the right product when you do find it, or knowing you have the right item in hand within seconds. This is what separates your business from frustrating delays and agitating customers to timely deliveries and raving reviews–and is what the right labeling setup can help facilitate

So, how do you master warehouse labeling?

Why Warehouse Labeling Matters

Imagine searching for a needle in a haystack, blindfolded. That’s what picking, packing, and stock taking can feel like in a disorganized warehouse. Think time is money? You bet it is. A study found that incorrect labeling is costing organizations an average of $89,000 annually.

But, instead of frantically searching aisles, your pickers could be zipping through tasks, thanks to a barcoding system and clear labels that guide them right to the item they need. The same goes for packing and stock taking – clear labels minimize errors, ensure accuracy, and free up valuable time for other crucial tasks.

But the benefits go beyond speed. Mislabeled items lead to incorrect shipments, a nightmare for customer satisfaction and your bottom line. Imagine sending the wrong dress color to a client planning their dream wedding! Proper labeling ensures the right item goes to the right place, every time.

Industry-Specific Labeling Concerns

Now, let’s talk about safety and compliance. For industries handling perishables or hazardous materials, clear labels are more than just convenient; they’re crucial. Expiration dates, lot numbers, and handling instructions printed directly on labels ensure safety protocols are followed and regulations are met. Even having the ability to include images and adjust font sizes can ensure the right attention and focus is being paid to products. Labels serve as an extra layer of protection for your employees, customers, and brand reputation.

Perishables

Expiration dates, lot numbers, and storage temperature requirements are vital information that must be clearly displayed on labels. This ensures proper rotation, prevents spoilage, and safeguards consumer health. Additionally, specific handling instructions, like “keep refrigerated” or “do not stack,” can be incorporated to optimize freshness and minimize waste.

Hazardous materials

When dealing with hazardous materials, clear and compliant labeling is non-negotiable. Global Harmonized System (GHS) pictograms, hazard statements, and precautionary information must be prominently displayed on labels to ensure proper handling, storage, and transportation. Adherence to regulations like DOT and OSHA is crucial, and effective labeling plays a critical role in meeting these requirements. Many Finale users customize their labels in exactly this way (by adding images), and for exactly this reason.

Industry-specific regulations

Each industry has its own set of regulations regarding labeling. Food and Drug Administration (FDA) guidelines for food labeling, for instance, differ from the Environmental Protection Agency (EPA) regulations for hazardous materials. Understanding and adhering to these specific requirements is essential. By incorporating industry-specific information on labels, you can demonstrate compliance, mitigate risks, and protect your business from potential penalties.

Key Labeling Principles

Building a solid house requires the right foundation. The same goes for effective warehouse labeling. While it might seem simple, choosing the right materials, design, and technology sets the stage for smooth operations and skyrocketed efficiency.

- Material matters: Imagine a label peeling off mid-shipment, leaving you with a sticky mess and a confused customer. Yikes! That’s why choosing the right label material and adhesive is crucial. Consider your environment: are temperatures frigid or warm? Is there moisture or abrasion? Matching the material to the conditions ensures your labels stick where they belong, rain or shine.

- Readability is critical: Tiny, blurry fonts are the enemy of efficiency. You don’t want your pickers squinting at labels or deciphering cryptic text under a time crunch. Clear, consistent font size and style are key. Opt for bold, sans-serif fonts and a size easily readable from a distance. Remember, clear labels translate to fewer errors and faster picking times.

- Leverage barcoding: With so many technologies at your disposal, you shouldn’t settle for pen and paper. Barcodes store product information scannable by handheld devices, enabling instant identification, accurate order picking, and reduced errors. Plus, they work seamlessly with inventory management software, further streamlining your operations.

- The power of RFID: RFID tags take things one step further. These radio frequency chips offer superpowers like tracking items in real-time, even without line-of-sight scanning. Perfect for high-volume warehouses or items requiring extra tracking, RFID offers unmatched accuracy and efficiency.

Remember, consistency is key. Finale’s custom barcode labeling printing ensures a high level of consistency by using the same label format, font, and barcode placement across your entire warehouse. This creates a familiar system, minimizing confusion and training time for new employees.

Advanced Strategies for Warehouse Optimization

Once you’ve covered the basics, it’s time to explore advanced strategies to maximum efficiency.

- Color-coding for intuitive navigation: Forget deciphering complex codes. Designate specific colors for product categories, aisles, or zones. This visual cue helps even new employees to locate items quickly and effortlessly. Imagine red for electronics, green for cleaning supplies, and blue for perishables – color association translates to faster picking and fewer errors, while adding a vibrant touch to your space.

- Zone labeling for streamlined routes: Zone labeling helps you divide your warehouse space into smaller, clearly labeled zones (e.g., Zone A, Zone B). This serves as a map for your warehouse, enhancing organization and optimizing picking routes. Pickers know exactly where to head, minimizing travel time and wasted steps. It’s like having a built-in navigation system for your inventory.

- Software integration for real-time visibility: Imagine scanning an item’s barcode and instantly seeing its stock level update in Finale’s inventory management software. No more manual counts, no more discrepancies. This powerful integration ensures accuracy, simplifies tasks, and grants you complete control over your inventory, accessible anytime, anywhere.

Pro Tip: Maximize efficiency by combining these strategies. Create color-coded zone labels and link them to your software for an unbeatable trifecta. Your warehouse will be the height of productivity, and you’ll be the master of optimized inventory control.

Achieve Warehouse Efficiency with Clear Labeling

Effective labeling isn’t just a warehouse perk; it’s the key to productivity. Warehouse labeling enables:

- Pickers find items in seconds, not hours

- Accurate and effortless stock counts

- Seamless flow of inventory and timely deliveries

- Compliance assurance

To unlock the full potential of your warehouse, consider investing in a robust labeling solution like Finale Inventory. Our custom barcode label printing services seamlessly integrate with your existing inventory management software, allowing you to generate clear, compliant labels directly within the system. Say goodbye to manual processes and hello to automated label printing, real-time updates, and unparalleled efficiency.