Supercharge Your Inventory Management with Barcode Scanning

A Powerful Barcode Scanning Solution That Automates Your Inventory Processes

Reduce fulfillment errors with Finale Inventory's seamless barcode scanning capabilities. Streamline operations by receiving stock, fulfilling orders, and conducting stock counts with this barcode and scanner software.

An All-in-One Barcode Solution to Solve Your Warehouse Problems

Increase Productivity

Reduce fulfillment errors and boost accuracy, as proven by Microfiber Wholesale's improved fulfillment process. Cut down on human error by locating products within the warehouse, even down to bins, with warehouse-guided picking directions.

Eliminate Fulfillment Errors

System-directed order picking minimizes travel time in the warehouse, letting your team fulfill more orders in less time. Get step-by-step directions from the scanner app to save walking time.

Accountability, Rapid Onboarding, and Team Tracking

Barcode scanning improves inventory management by tracking who picks, receives, or adjusts stock, ensuring visibility and accountability. Its clear, step-by-step instructions help new hires contribute quickly, reducing training time and effort while guiding them on what to pick and where to find it. Additionally, managers can monitor daily orders and individual user activity to reward high achievers and address training needs effectively. Minimize the training requirements on product and SKU knowledge.

Finale Inventory. The Ultimate Barcode Scanning System.

This turnkey barcoding and labeling solution streamlines warehouse operations by enabling on-the-spot quality checks to reduce fulfillment errors, delivering greater efficiency and accuracy at a fraction of the cost of a custom system. Gain unparalleled accuracy, boost productivity, and streamline your operations to take your business to new heights of success.

Receiving Shipments

Optimize your warehouse operations with cloud-based, scalable shipping and receiving software. The shipping a receiving capabilities were designed with multi-store and multi-warehouse environments in mind. Verify the accuracy of your inventory at the point of entry to your warehouse or store location by scanning upon arrival.

Serialized Inventory Made Easy

Effortlessly track serialized items using existing manufacturer barcodes or unique serial numbers. Simplify processes and maintain precise control or serialized assets or products.

Streamlined Stock Counts

Multiple staff can efficiently perform stock counts simultaneously, scanning bins and updating totals in near real-time.

Custom Barcode Labels

Create and print custom barcode labels, eliminating the need to purchase additional software for label generation. Print your own SKUs as labels or even FN SKUs.

Bin Location Tracking

Quickly locate inventory by bin, see exact stock counts per location, and maintain accurate bin details.

Order Picking

You can pick orders with the barcode scanner using a variety of methods. Choose from basic picking (one order at a time) or batch methods like pick and pack, wave picking, or batch picking.

"Through [Finale's] wireless barcode scanning system, we have increased both productivity and accuracy. Using the 'guided picking' feature, order picking is a breeze and easy for old and new employees to understand as the scanner determines the most efficient picking order and guides them to the correct standard bin."

Yes, if you already use ShipStation you can easily connect Finale Inventory with the powerful integration.

Yes, you can scan in shipments to your warehouse or retail location as part of your procurement workflow.

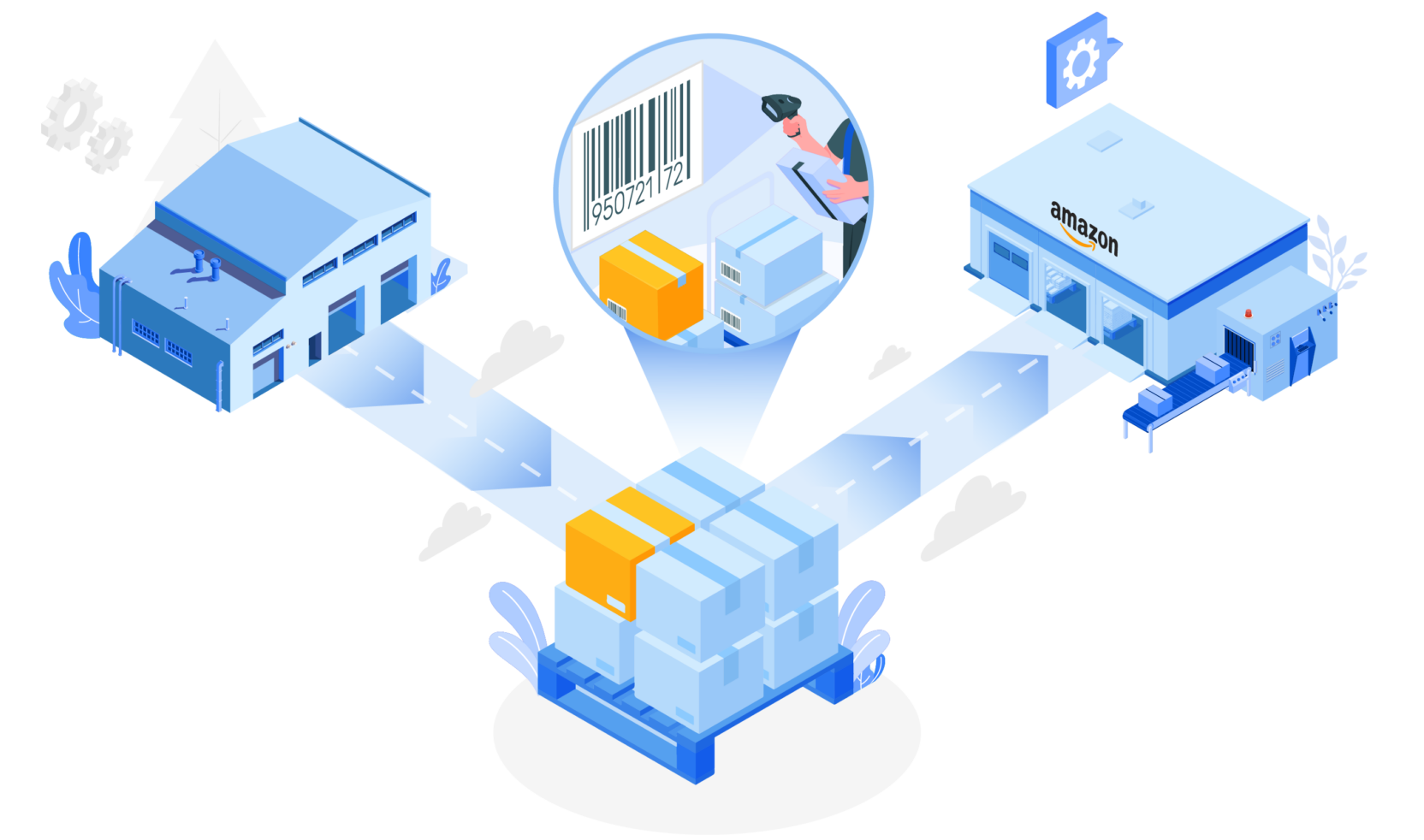

Yes, you can use easily sync transfer orders from Amazon Seller Central, then pick and pack shipments to get them sent to Amazon's fulfillment centers easily.

Yes, this system can generate unique labels. Learn more about scanning and labeling.

Use Finale's label printing solution.

There's more to printing labels for inventory than you might think. If your warehouse operations encounter issues with stocking, high costs, low efficiency or tracking errors, you may need to rethink your labeling system. Finale Inventory offers custom barcode label printing services that can integrate with inventory management software to give you up-to-date information about all your stock.

Yes, quickly conduct stock takes and stock counts with the handheld scanner. No more manual counting with clipboards and paper.