Reorder Point Control System

Reorder Point Control System

With more than 18,000 product warehouses and over 1 million retail stores across the United States, how can you help your establishment stand out from the rest? By maintaining a reliable inventory and being ready to meet customer and client demands with quality service and speedy fulfillment. One of the most critical parts of maintaining an accurate inventory level is establishing an inventory reorder point for each product and using that information to submit orders manually or through an automated service.

To set your business up for success, explore the definition of reorder level, why it’s important and how to calculate reorder points for inventory.

What Is Reorder Level and How Does It Apply to Me?

The reorder point — sometimes known as the reorder level — is an essential piece of information for every retailer and supplier. The reorder point is what ordering managers or automated software systems follow as a guideline for ordering new stock.

After calculating the correct unit quantity with the help of a reorder point calculator or formula, that number becomes the minimum amount of products you will always have on hand before you or the system automatically orders more. It lets the ordering manager or management software know that it's time to refill an order for items to reach your store before the rest of your inventory depletes.

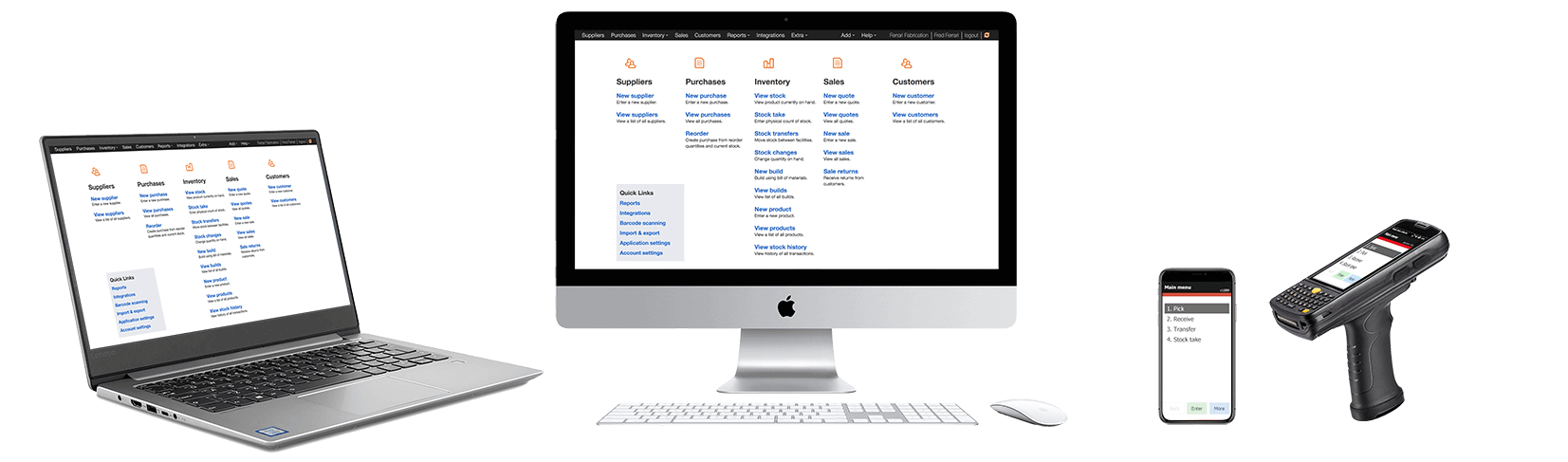

An Example From Finale Inventory

We put together a video to help you gain a better understanding of how you can use Finale cloud inventory management software to supplement your reorder point system. In the video, you’ll see how to use Finale Inventory to schedule reorder points that trigger our system to reorder stock for you.

Here’s how it works:

- Open your Finale Inventory account and navigate to the Home page.

- Select “View Products” and wait for the page to load. For this example, we’re going to imagine you operate a business that sells pies.

- On the “View Products” page, search the term “pie.” You’ll see each type of pie currently in stock.

- Select your chosen pie, and it will take you to a new page where you can see the reorder quantity, like 10 pies.

- When you go to Home and click “View Stock,” you can see how many pies you currently have in stock. Right now, your pie levels are all above the reorder point.

- For the sake of this example, imagine a customer then purchased 15 of your in-stock pies. Once they’ve shipped out, the stock availability of those pies goes down.

- Going back to “View Stock,” you will see your current stock reflects the changed number of available pies. Let’s say you’re now left with six pies.

- Visit the “Reorder” page and search for your pie manufacturer. You will see the quantity on hand, your preestablished reorder point and the difference between those two numbers. You’ll see that the current purchase order active for that supplier has automatically filled in the difference for how many pies you now need to maintain your chosen base quantity. This is your reorder point.

- Once you receive your new shipment of pies and have reached your reorder point or beyond, our automated reorder point software and inventory management process continues to monitor and place orders as necessary.

Why Is Reorder Point Important?

Calculating and maintaining accurate reorder points for each item is an important part of running a retail business or supplier warehouse. It helps you accomplish the following key functions.

When Should You Reorder More Inventory?

You should reorder inventory when a specific item has reached the point where it may sell out before the next order arrives. This number will naturally fluctuate depending on your marketing strategies and seasonal trends, so it's important to oversee and revise your reorder points periodically. Using a reorder point software will help you manage these changes without taking up too much time.

How Many Units Should You Order

To calculate how many units you should order of a particular item, you need to consider the following changing factors:

Like your reorder date, your reorder quantity will change as these factors do. Things that may be bestsellers now may stop selling entirely next year, while slow-moving products might see a spike in demand without warning. It’s essential that you keep accurate records or work with an inventory management software that can do it for you. Audit your inventory regularly and seek out new suppliers with better products or prices as needed.

How to Calculate Reorder Point for Inventory

Now that you understand the importance of establishing and maintaining accurate reorder points for each item in your inventory, it’s time to calculate. Fortunately, the formula is simple — multiply the item’s lead time in days by its average daily sales velocity and add that number to the number of units set back for safety stock.

Let’s break it down:

Safety stock:

Safety stock are those items you’ve set back as emergency-use only. Emergencies could include delayed shipments from vendors caused by hazardous weather or seasonal demand, an unexpected increase in sales or your nearby competitor closing their doors, sending an influx of customers your way. Your safety stock acts as a buffer in these situations to keep you from completely running out of an item. While dipping into safety stock is expected, you should never use it as a replacement strategy for establishing an accurate reorder level.

Lead time:

Lead time demand refers to how long it typically takes your supplier to receive, process, fulfill and transport the order to your store. Calculate lead time by looking at previous sales records for the current month, season and year, and determine the average wait time in days. Your reorder point should take lead time into account so you don’t run out of stock while waiting for a shipment and resort to dipping into your safety stock.

Daily sales velocity:

This is the average number of a specific item you sell in a day. Calculate this amount by adding up the total number of sales for an item over a set timeline, then divide the total by the number of days in that period. This is your average daily sales velocity. Each product in your inventory has a separate average.

Finale Keeps Reordering Simple, Easy and Fast

Inventory management software from Finale Inventory makes reordering your stock fast and stress-free. Our reorder point formula considers your real-time inventory levels, so you always have an accurate reading. Finale lets you establish reorder levels for each item and implement automatic reorders to free up time and keep operations running smoothly.

Inventory automation reduces the room for human error and miscalculation, making your business more efficient and profitable. The best part is that inventory management software is scalable, so as your needs and inventory change, our program will adapt and guide you through the transition.

Get Started With Finale Inventory Today

Accurate reorder points play a crucial role in your daily operations. When implemented correctly, you can leverage them to make smarter financial decisions and build stronger relationships with your customers. If you're ready to take control of your retail store or warehouse inventory, Finale has the software you need. Take a video tour to learn more about our platform and features, or schedule a demo to see what Finale can do for your business.

Reorder Point Video Resource: