Serial Number Tracking

Easily Track Serial Numbers for Better Inventory and Warehouse Management

Track serial numbers with precision using Finale Inventory's serialized inventory management software, designed to ensure accurate item tracking and detailed record-keeping. Maintain control and accountability across your entire inventory system.

Gain Visibility and Track Your Serialized Inventory

What Is Serial Number Tracking?

Serial number tracking is a method used to manage and monitor individual items in your inventory by assigning a unique identifier, or serial number, to each unit. This lets you trace specific products through their lifecycle, from manufacturing to the sale and beyond. It’s especially useful for industries handling high-value items, warranty claims, or regulatory requirements, as it ensures traceability for returns, repairs, audits, and realls.

Examples of Serial Number Tracking for Inventory Management

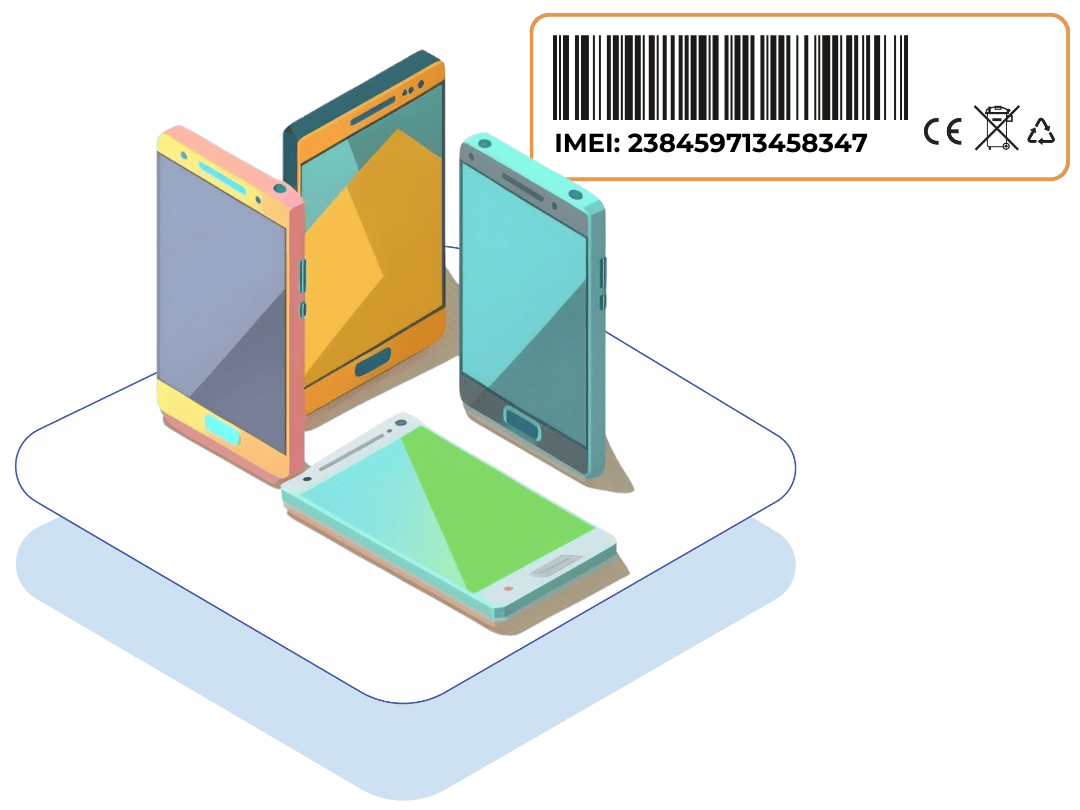

Electronics Industry: Tracks products like smartphones, laptops, and appliances to validate warranties, manage repairs, and prevent counterfeiting. Finale can track IMEI numbers for mobile phones when selling, shipping, or transferring stock, allowing businesses to track which device was sent to which customer.

Automotive Industry: Serial numbers let you monitor vehicle parts, engines, and tires to manage recalls, warranty claims, and maintenance records for safety and reliability.

Solar Industry: Tracking serial numbers of solar panels is essential for managing installation, repairs, warranties, and manufacturer recalls. Solar companies can quickly retrieve repair histories, verify warranty claims, and generate reports to locate specific solar panels or track all serialized stock at a given installation site or in storage.

Finale Inventory. The Ultimate Serial Number Tracking System.

Prevent Fraudulent Returns

Serial number tracking helps prevent fraudulent returns by verifying each product's unique ID at the time of purchase. This measure deters attempts to return stolen goods or trade older items for newer ones. When a return is initiated, businesses can quickly confirm whether the serial number corresponds to the original sale. As a result, they reduce financial losses, maintain accurate inventory, and shield themselves against return fraud.

Struggling to Track Serialized Stock? Finale Inventory Has the Solution

Managing serialized inventory across multiple warehouses or ecommerce channels can be overwhelming without a scalable system. Tracking manufacturer or custom-assigned serial numbers manually leads to errors, inefficiencies, and compliance risks.

Finale Inventory simplifies the process with barcode scanning, bulk imports, and flexible serial number configurations. Easily search for a serial number, track it through your inventory, or print it on shipping manifests, bills of lading, and sales orders. From receiving to shipping, Finale ensures complete accuracy, traceability, visibility, and control over your serialized stock.

Serial Tracking for Legal Compliance

Selling products that require serial number tracking, like medical devices, automotive, and firearms, comes with strict state and federal regulations. Without an efficient tracking system, keeping accurate records, ensuring compliance, and handling audits or recalls can become a major headache, leading to potential fines or legal issues.

Finale’s serialized inventory management software automates record-keeping by tracking each item’s serial number from receipt to sale. This ensures full compliance with regulations, simplifies audits, and provides a clear product history.

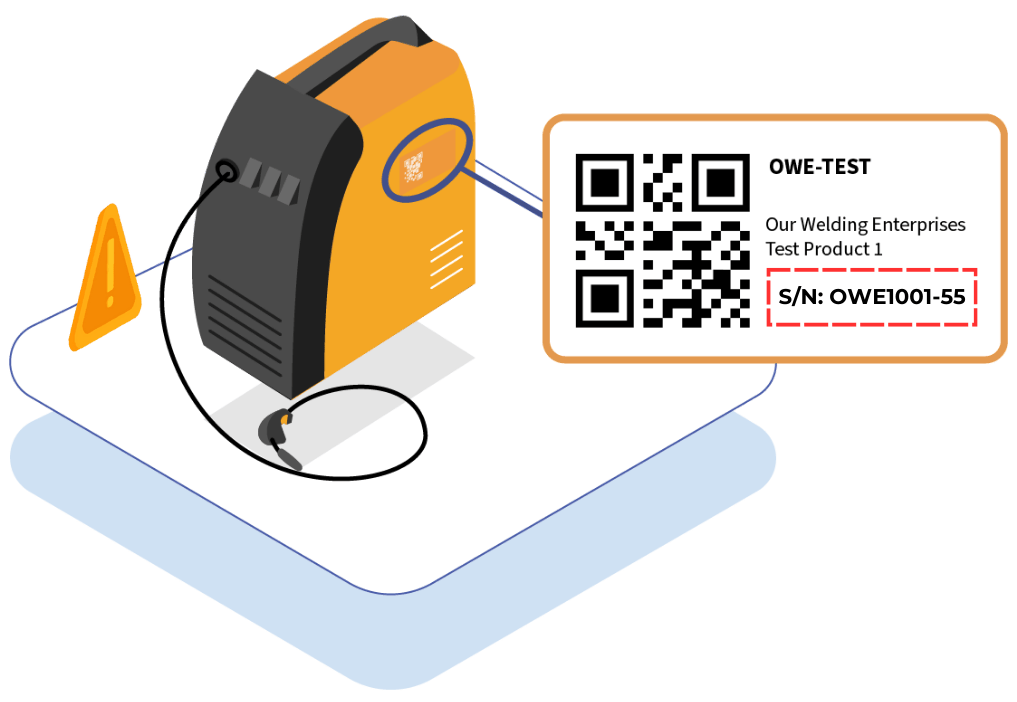

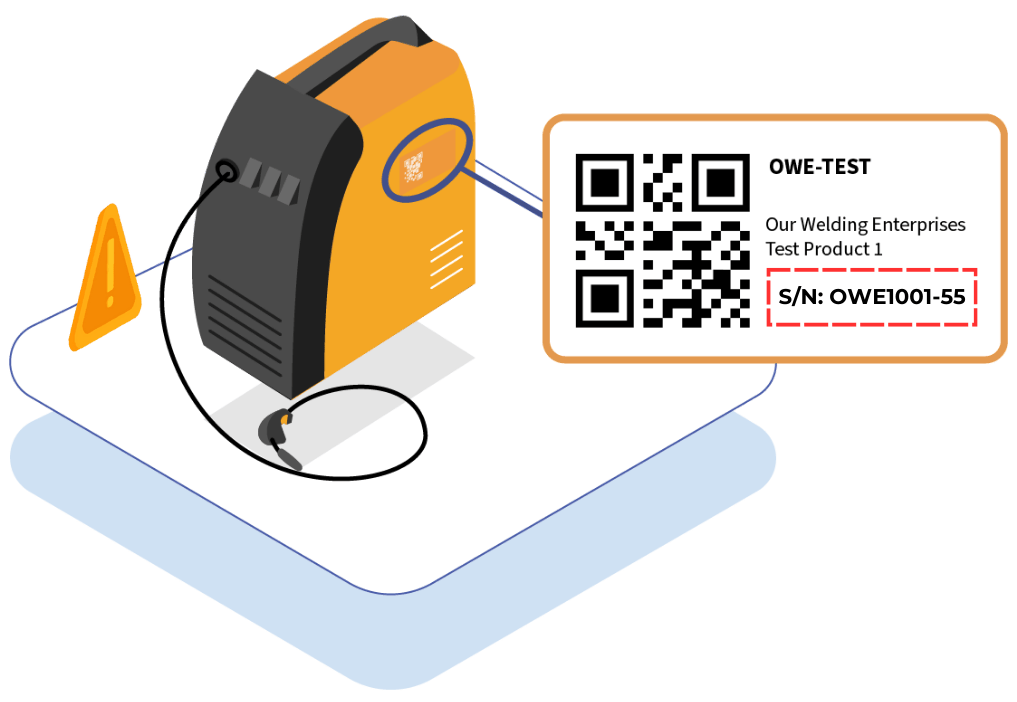

Use Finale’s Barcode Scanner to Track Serial Numbers

Receive serialized stock with the barcode scanner when it arrives at your warehouse or retail location. The mobile barcode scanner can recognize the manufacturer’s barcode, making the intake smoother. Within Finale you can print a unique barcode label for products that have a serial number.

When there is a sale and you pick the order, by scanning the barcode label, the serial number is automatically tied to that sale order and fulfillment. Without barcode scanning, tracking serialized stock is a grueling process, and that’s why when businesses grow, they use professional software like Finale with built-in barcode scanning capabilities.

"Before Finale, it was excruciating to keep track of our window film within Excel as each roll has its own serial number. Finale’s integrated mobile barcode scanner solution and its ability to track serial numbers has significantly reduced our inventory management complexity and streamlined our warehouse operations. I simply scan the serial number of the roll, and I am done!"

Yes, in addition to using the manufacturer's S/N, you can create your own unique id for a product.

It is on the Shipment in the LOT ID field where you document a serial number for an item you purchase or receive.

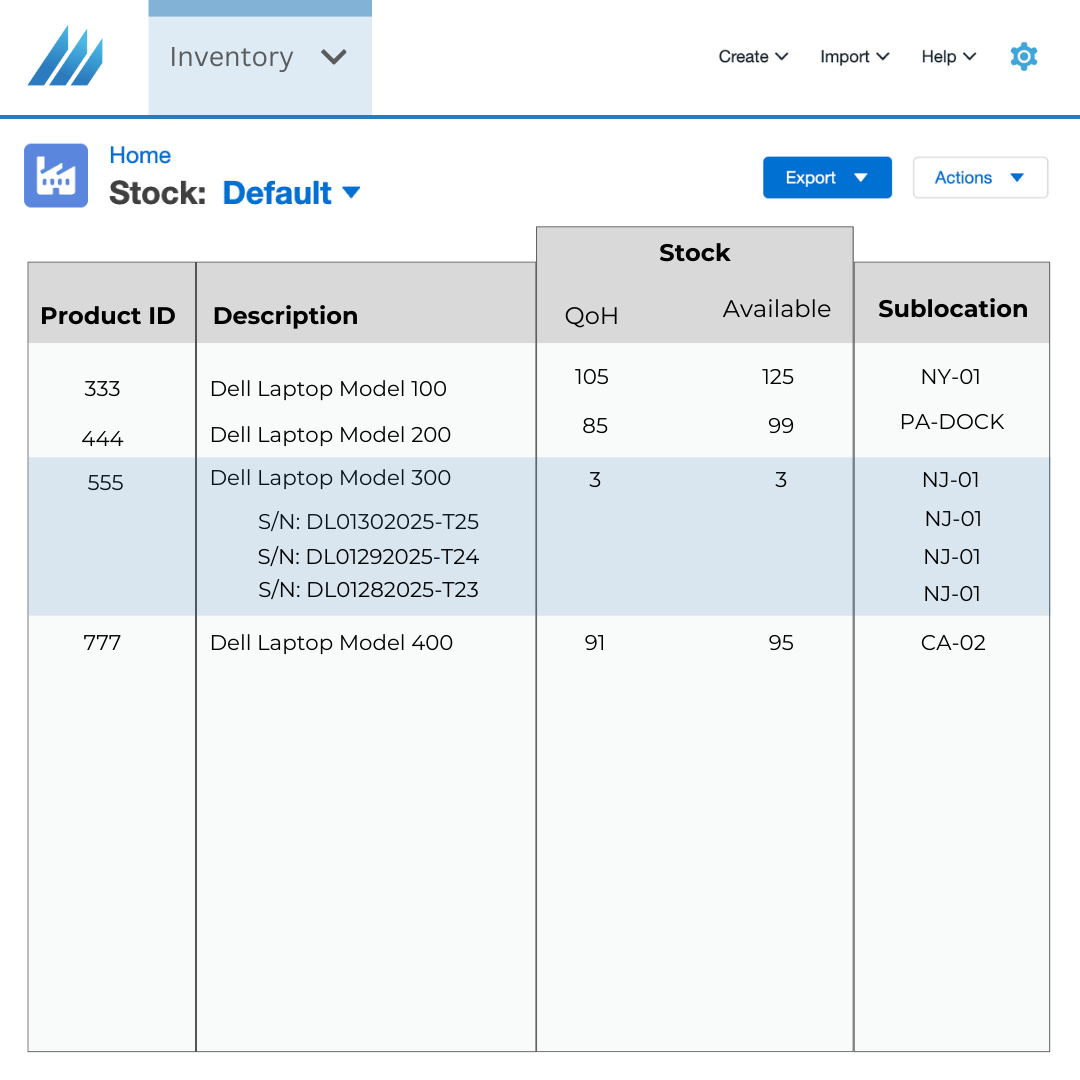

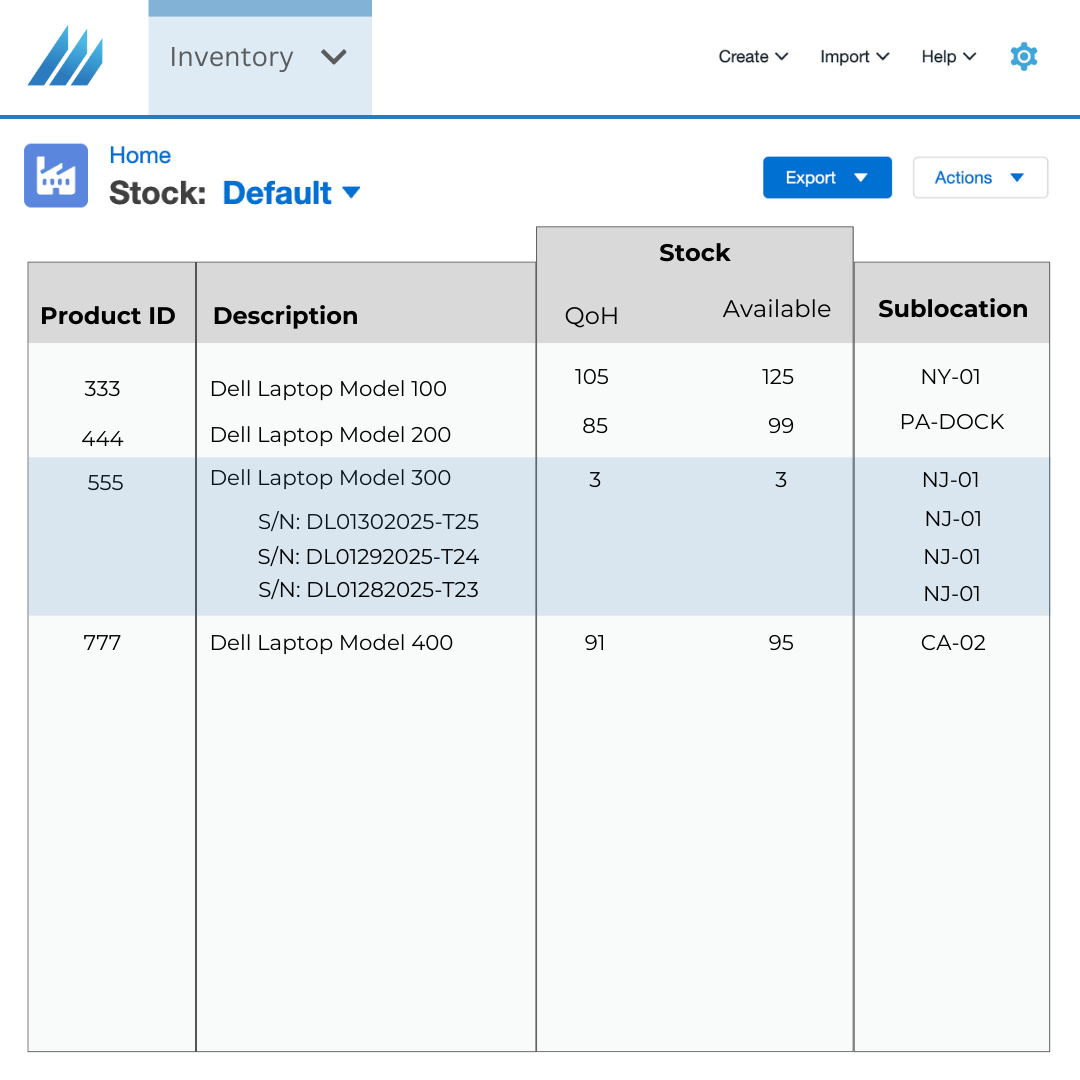

Once these unique identifiers are known to Finale Inventory, they will be visible on the Stock View screen when you expand the details for the Product id with the icon, on the left of the row.

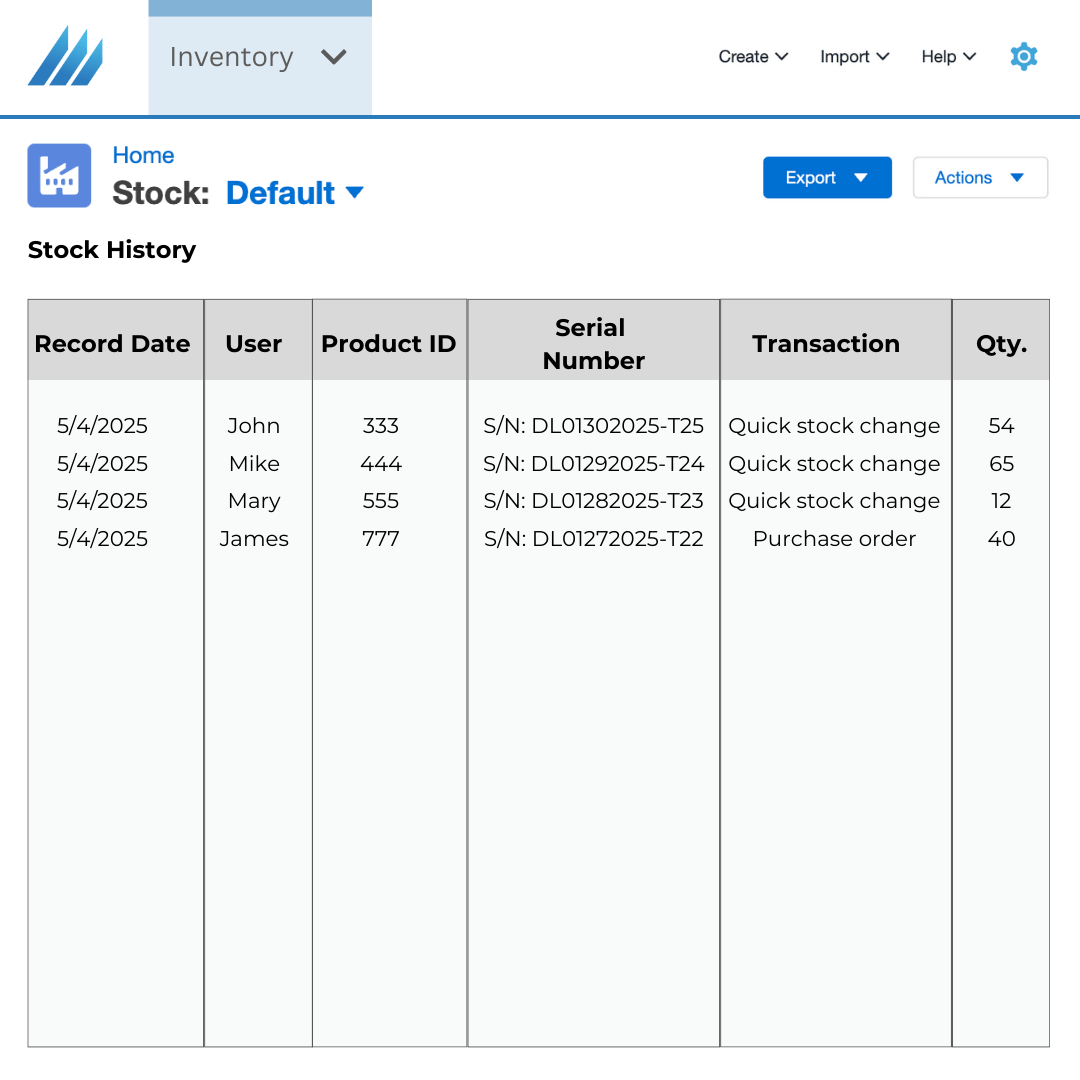

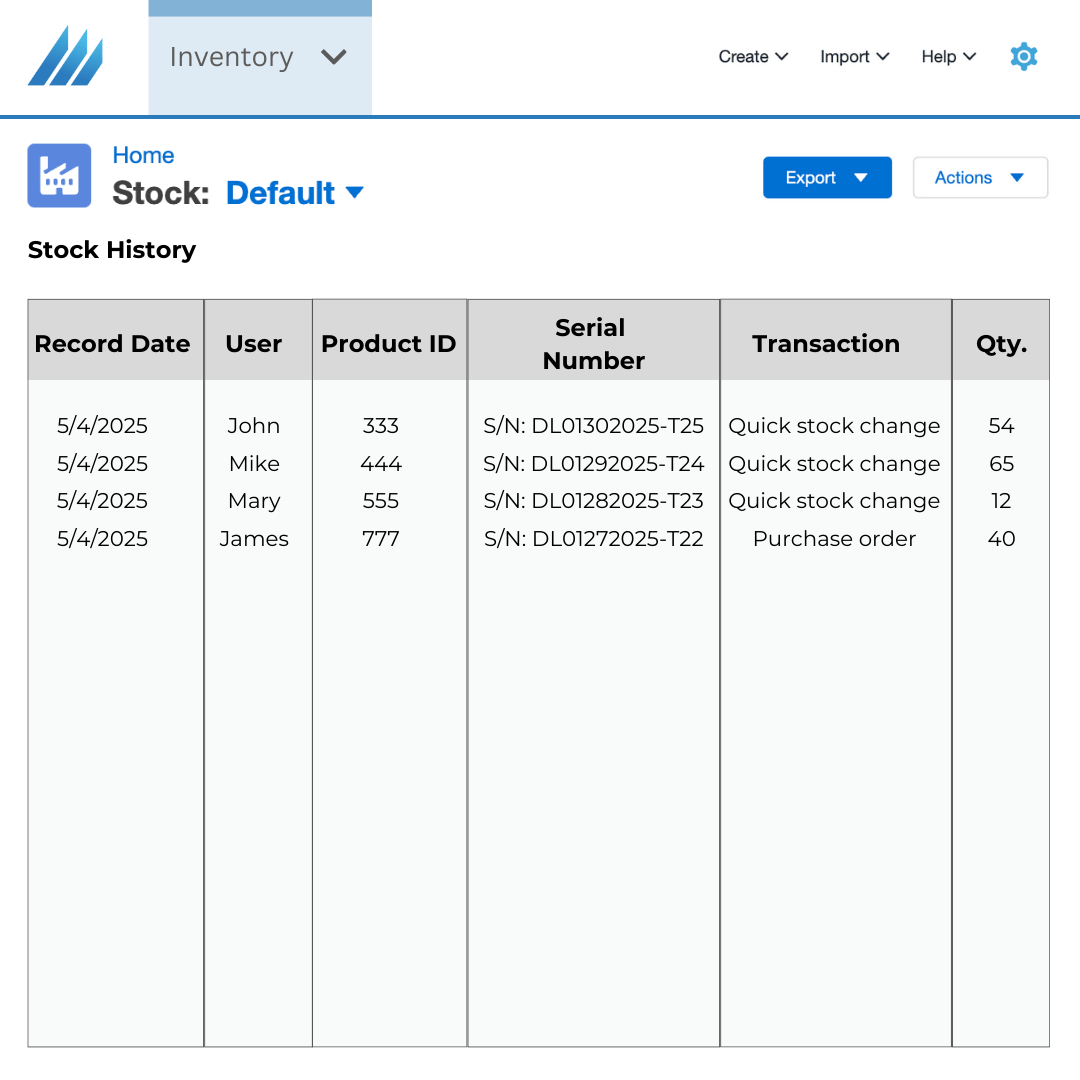

You can search all transactions for a specific serial number using the Stock History View Screen.

Yes, in Finale you can return an item with a serial number or IMEI. First, create a sales return, and then you can add in the serial number for that specific item.