Bill of Materials (BOM) Software

Streamlined Light Manufacturing & Assembly with Bill of Materials Software

Manage and track materials, components, purchases, and all of your inventory in one place. Never again run out of parts to complete your production with BOM software.

Bring Your Manufacturing & Inventory Together With BOM Software

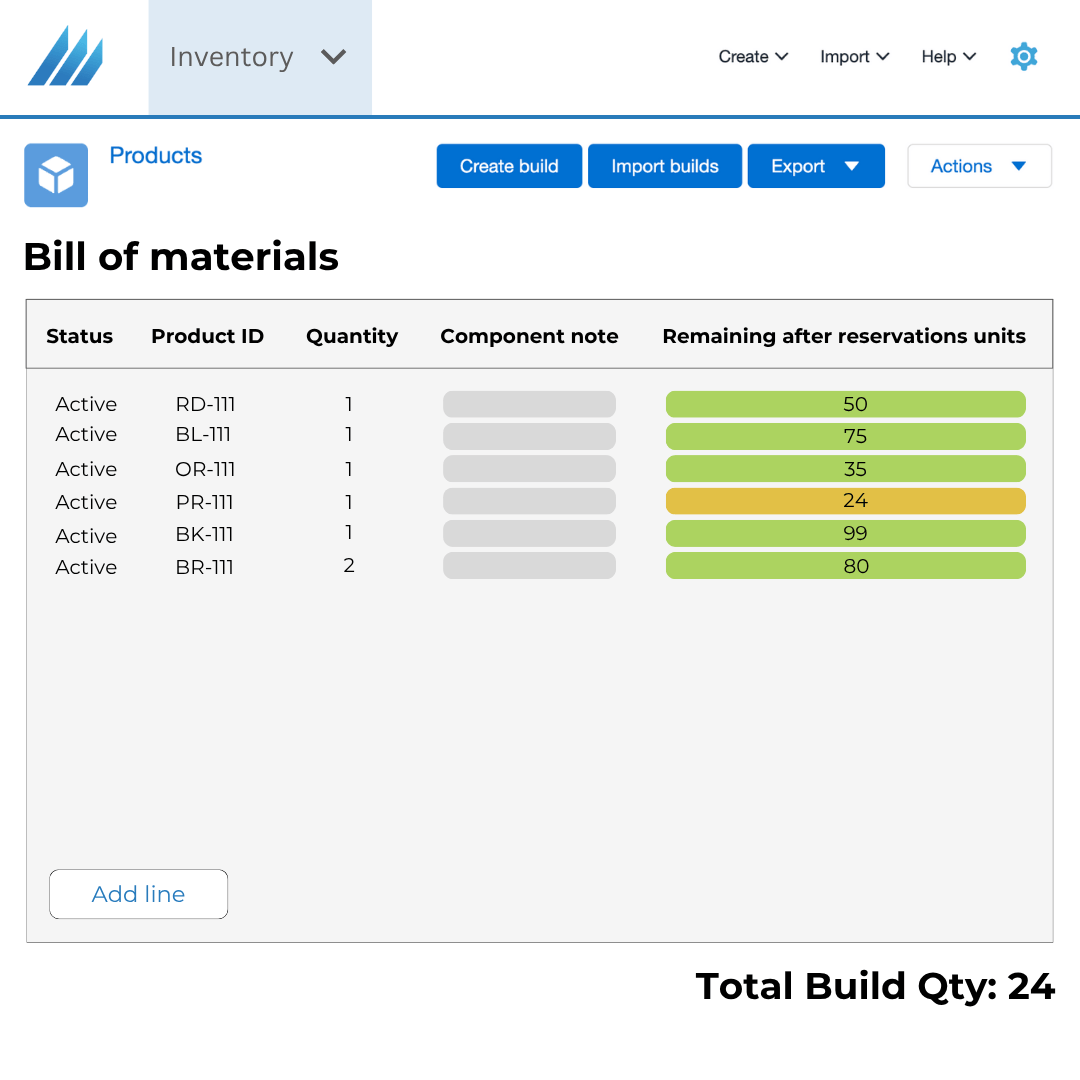

Automated Buildable Units Calculation

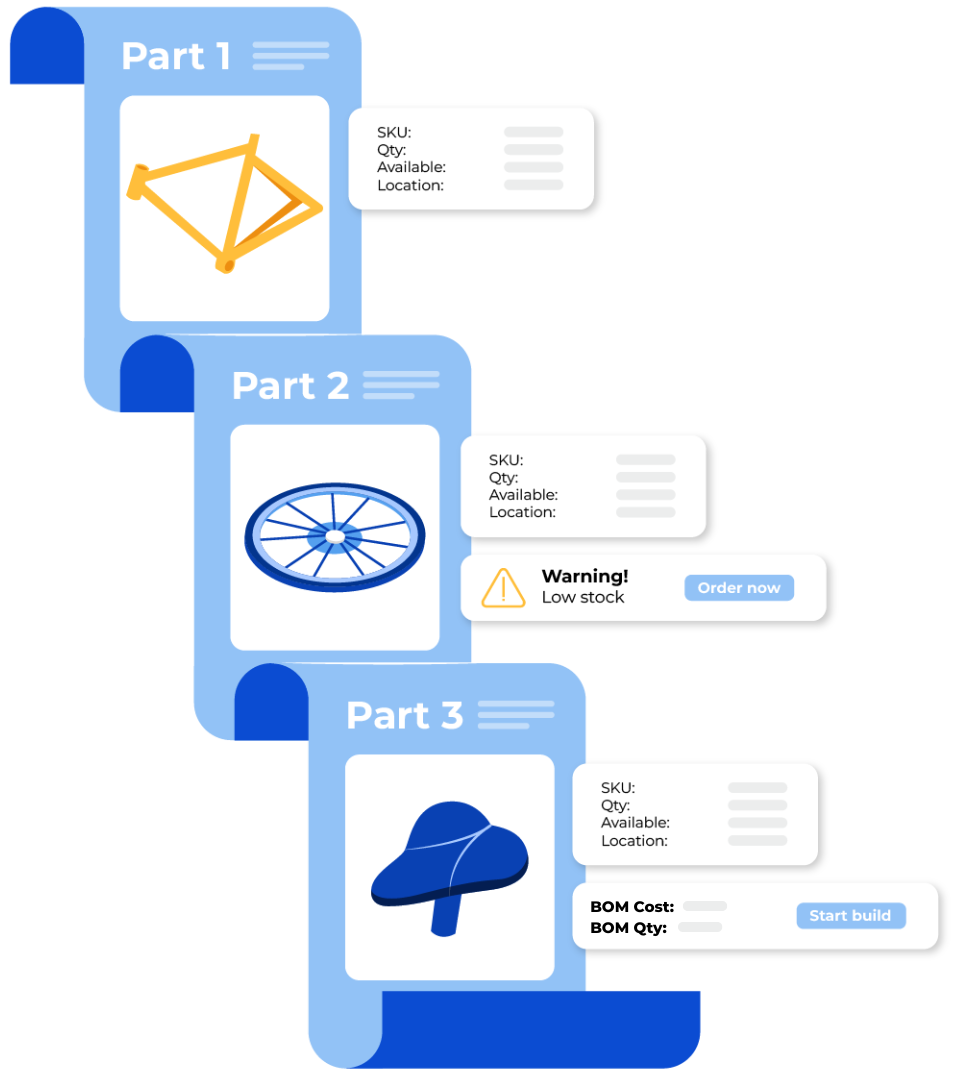

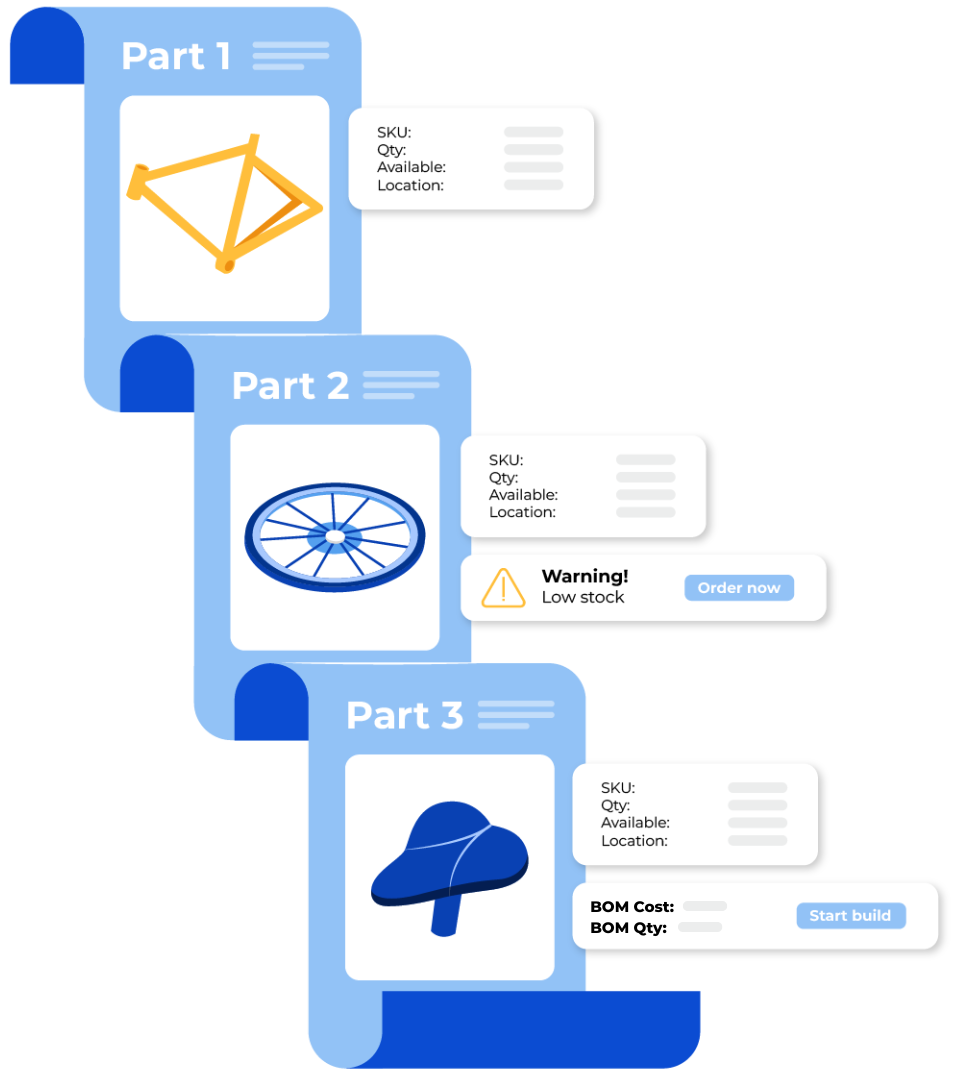

See how many units you can build, assemble, or produce based on your available materials and parts. Finale’s bill of materials software calculates how many units can be assembled with what is already in your inventory and reserved for orders in process, something Excel can’t do.

Efficiency & Error Reduction with BOM Software

Manual tracking of production orders and spreadsheets often leads to frequent errors, delays, and confusion. Inefficient management of assembly and manufacturing processes slows down production, impacting fulfillment timelines.

Finale Inventory automates your bill of materials, streamlining assembly tasks and reducing human error. By automating your workflows, Finale ensures consistent, accurate manufacturing processes, boosting productivity and on-time manufacturing. Businesses that track the quantities of each component manually turn to Finale’s BOM software for smarter assembly.

Material Purchasing With Responsive & Scalable BOM Software

When demand fluctuates or product complexity increases, managing material orders and inventory levels becomes overwhelming. Manual tracking leaves businesses either short on stock or burdened by excess inventory.

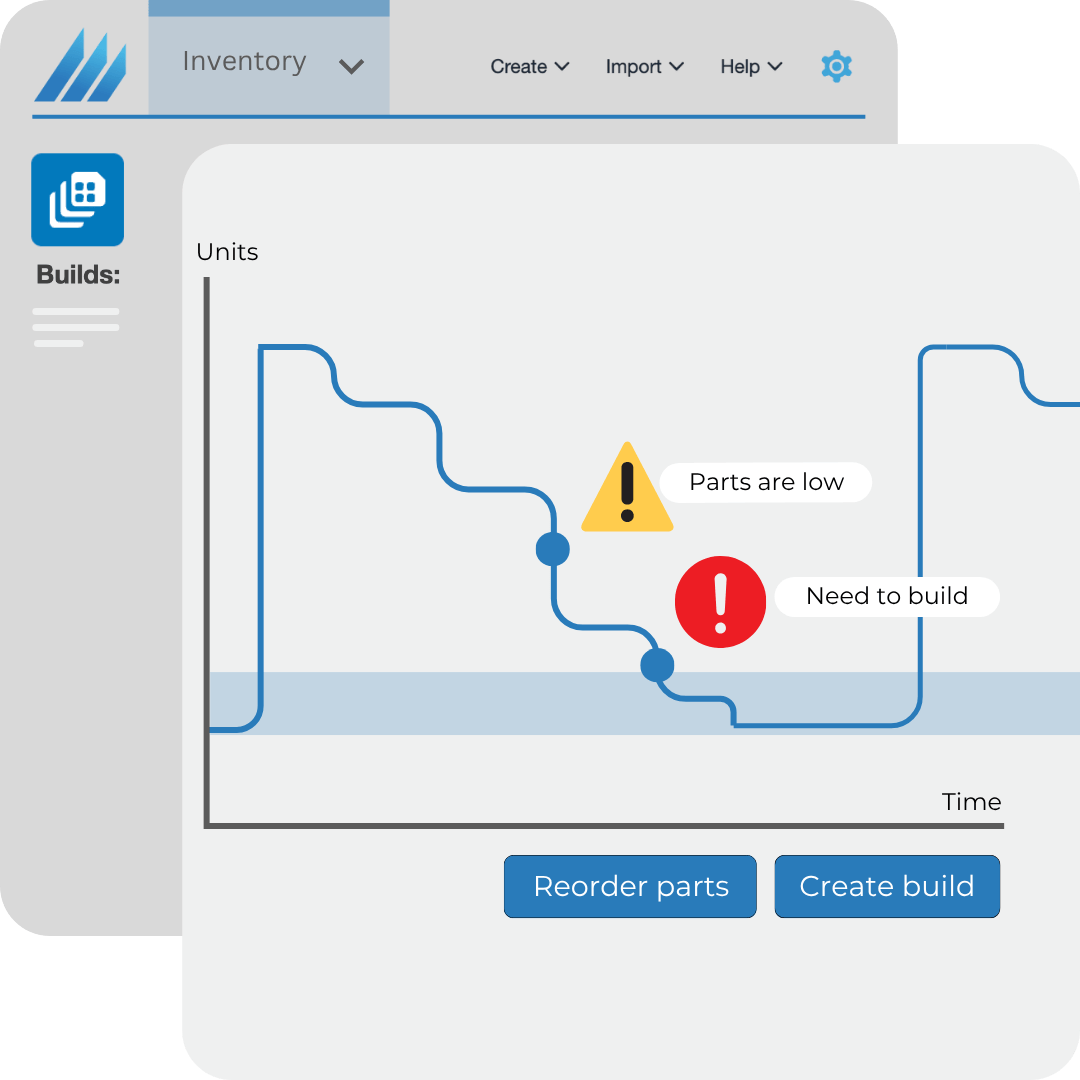

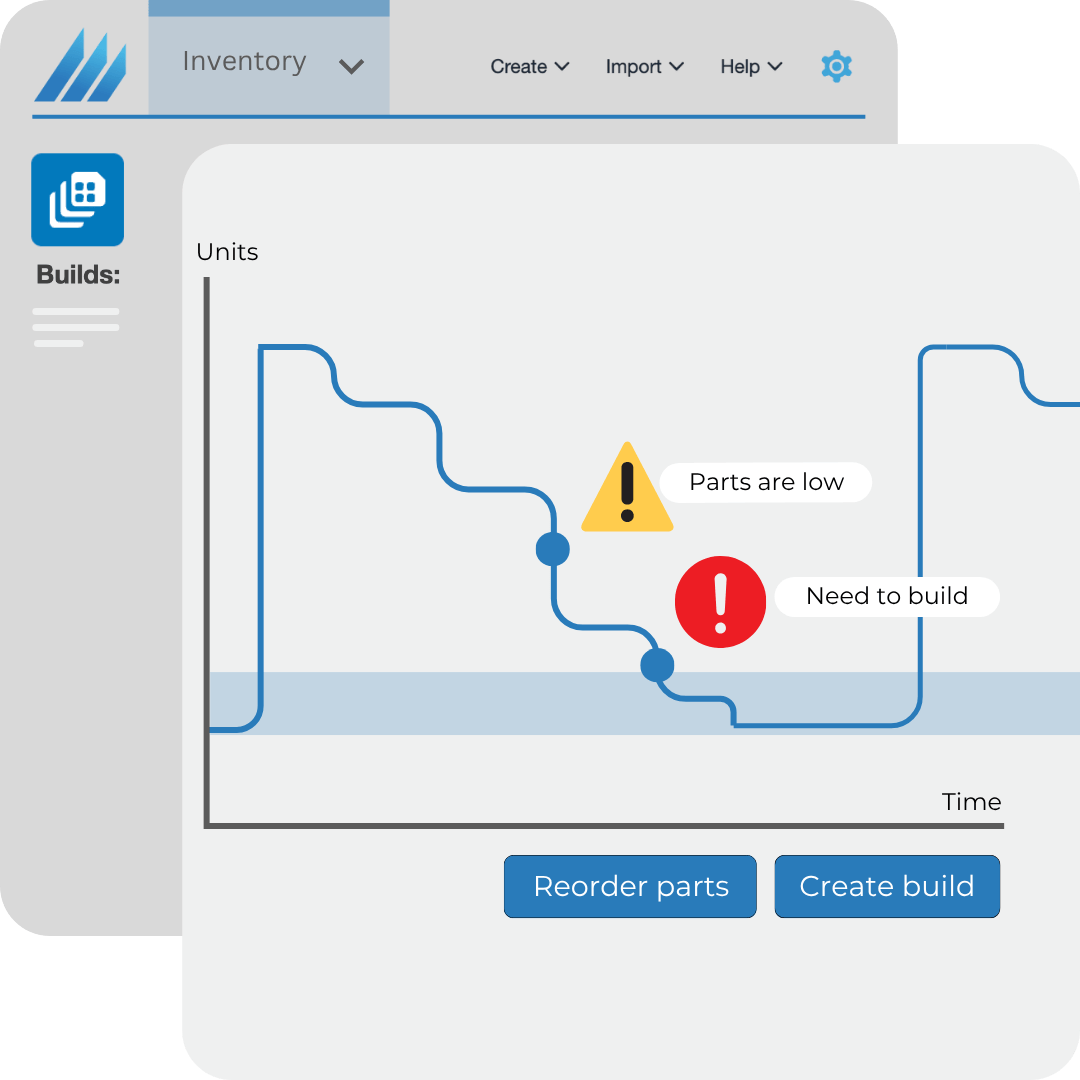

Finale Inventory’s BOM software offers dynamic, real-time insights that keep your inventory aligned with customer demand. Automated reorder recommendations prevent you from running out of material to complete your builds. Finale clearly shows when components are low, so you never run short.

Financial Visibility & Accurate Pricing

Inaccurate or incomplete visibility of component costs leaves businesses unable to reliably manage expenses and set profitable pricing. Hidden manufacturing costs can quickly erode margins.

Finale Inventory tracks your component costs in real time, providing detailed financial insights into your spend. Clear cost visibility empowers you to confidently manage expenses, price products profitably, and protect your margins.

Reduce Waste, Optimize Materials, Cut Costs

Inaccurate material planning, frequent over or under-ordering result in excess inventory, unused stock, shortages, and unnecessary scrap. Large ERP softwares address these problems but are very expensive.

Finale Inventory’s BOM software calculates material needs, reduces costly errors through automation, factors in supplier lead time, and allows you to set minimum order quantities, thereby lowering your production costs. Finale’s BOM functionality provides light manufacturing and assembly capabilities without the high cost or complexity of an ERP system.

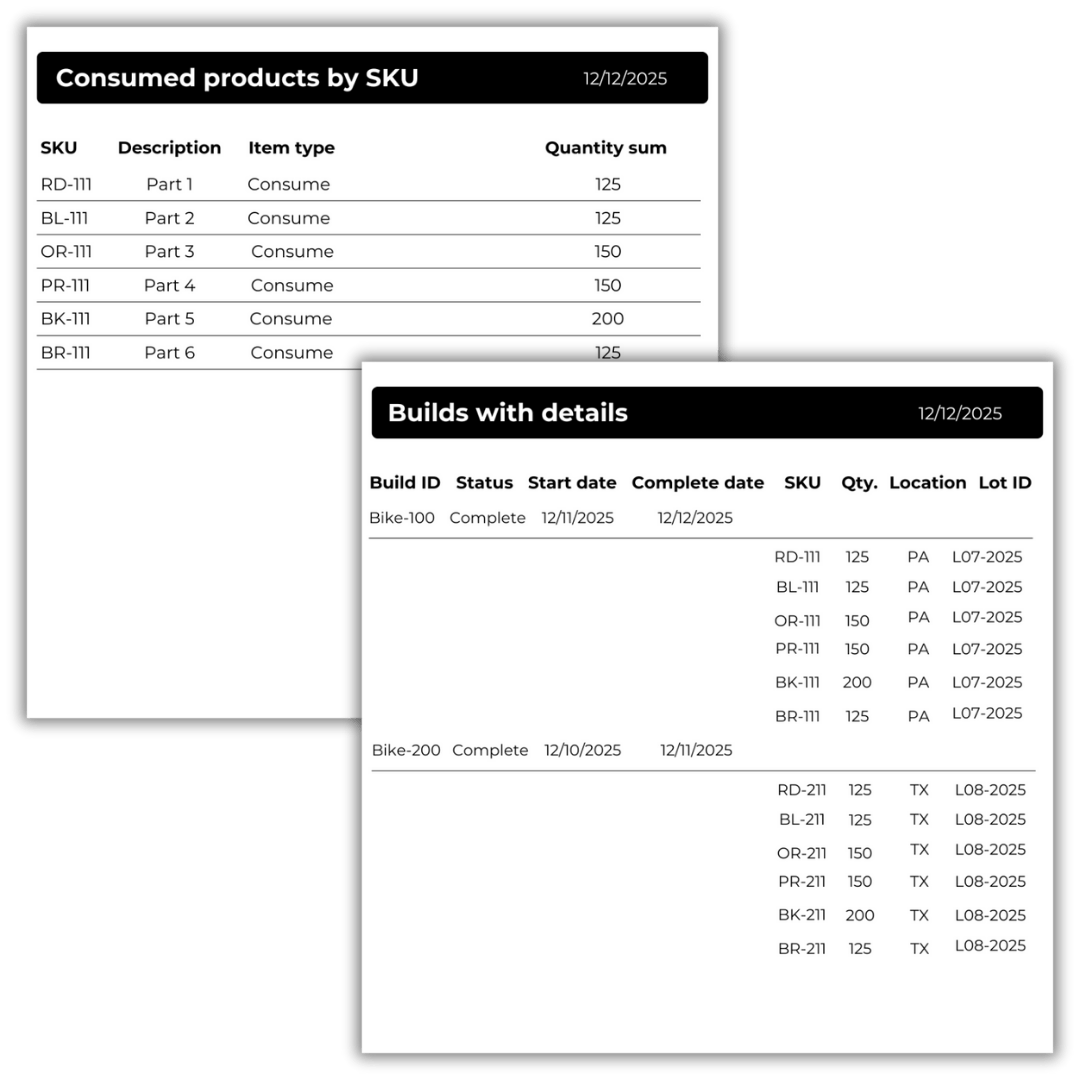

Quality, Traceability & Control With BOM Software

Without robust traceability, businesses struggle to maintain consistent product quality and regulatory compliance. Poor visibility into lot ID or serial numbers during production can trigger costly recalls, damage the brand's reputation, and lead to compliance issues.

Finale Inventory delivers comprehensive lot and serial number tracking, offering complete traceability from raw materials to finished goods. This ensures your products meet quality standards and requirements, protecting your brand. Log all your approved vendors and suppliers in one system, ensuring you never run out of parts to complete the assembly with high quality and on time.

"Our business manufactures items that require assembly and kitting. Finale's ability to manage and track each component individually as well as when complete kits are sold is very advantageous for our business. ...The ease of use and set up has been refreshing as we were able to get started within a few days, and training employees is a breeze.”

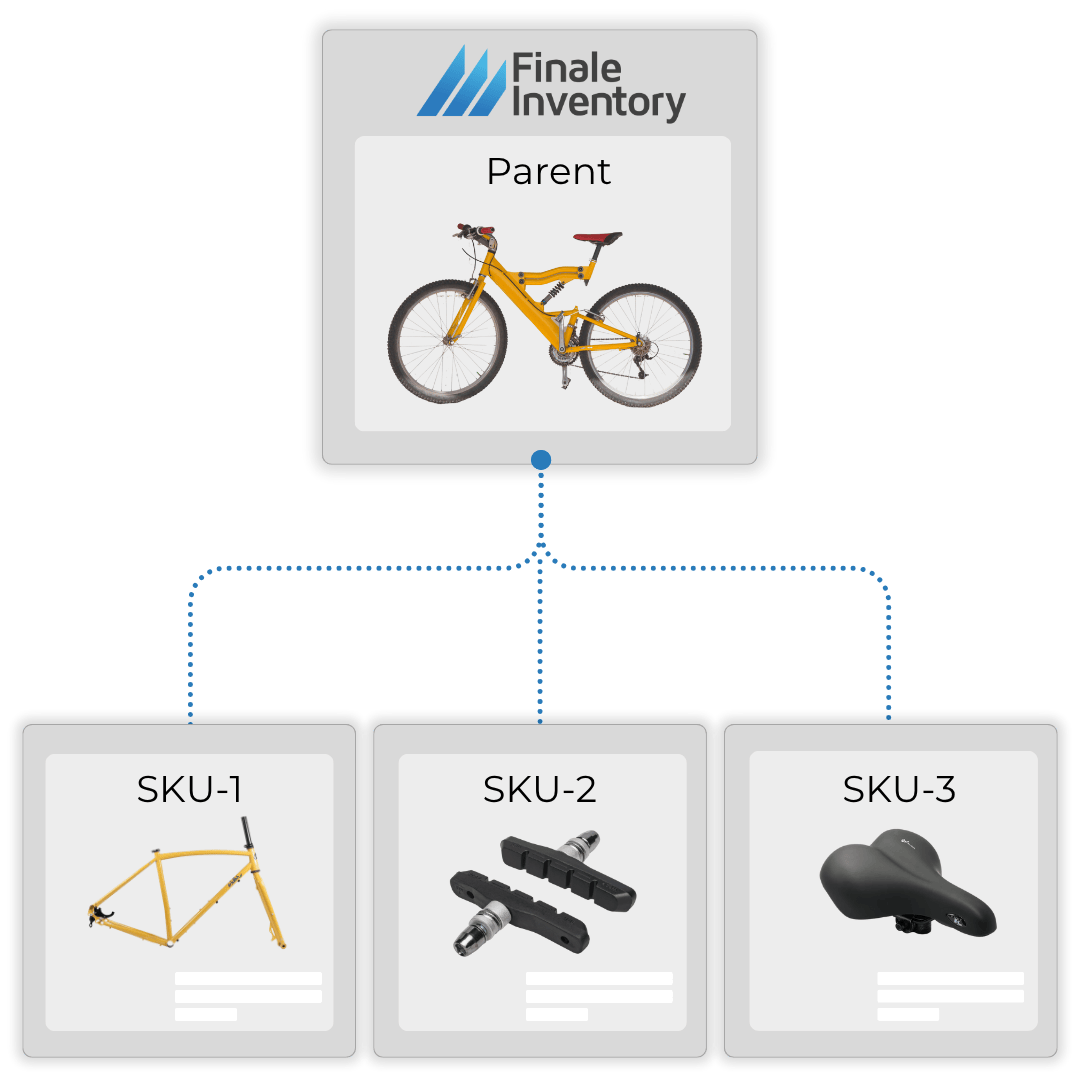

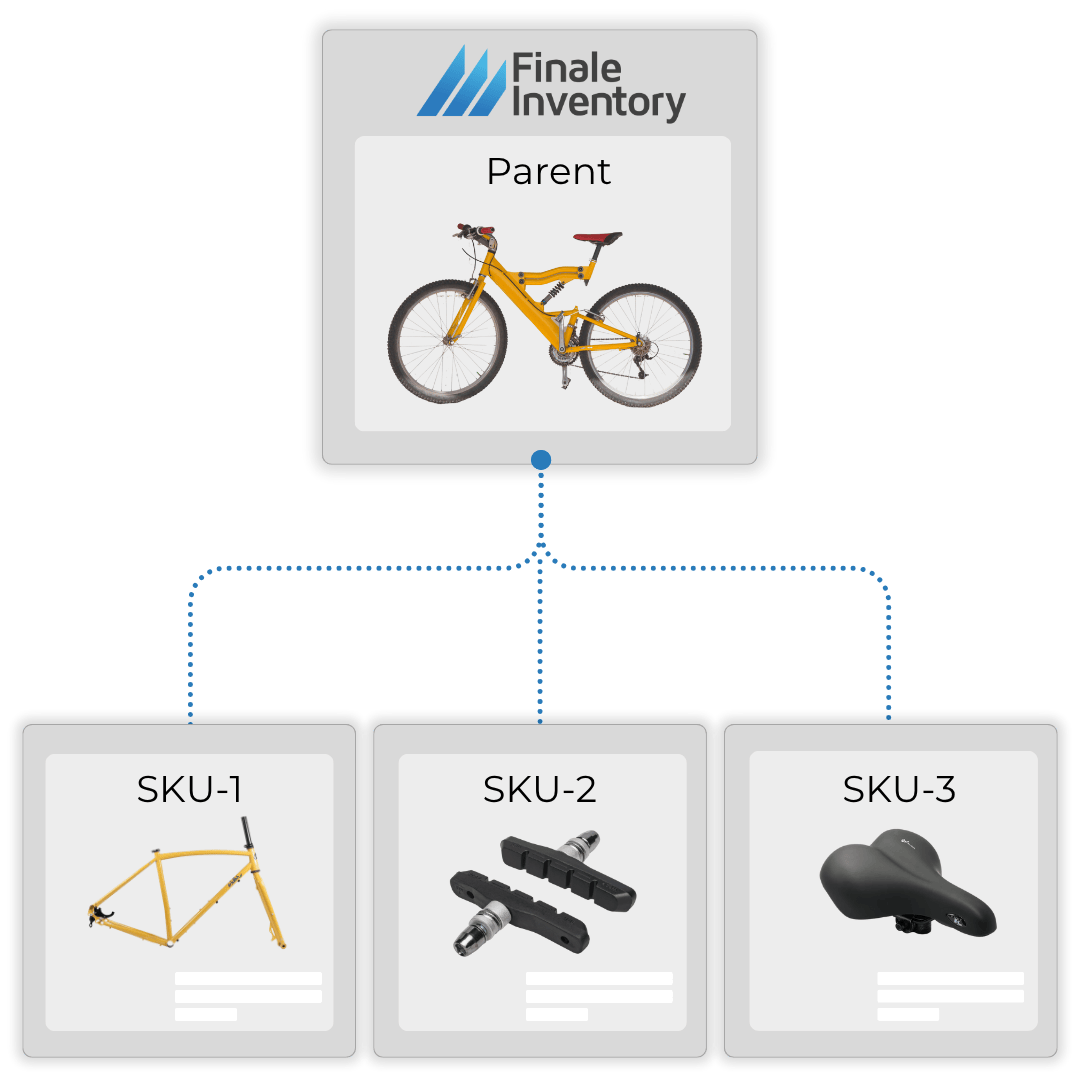

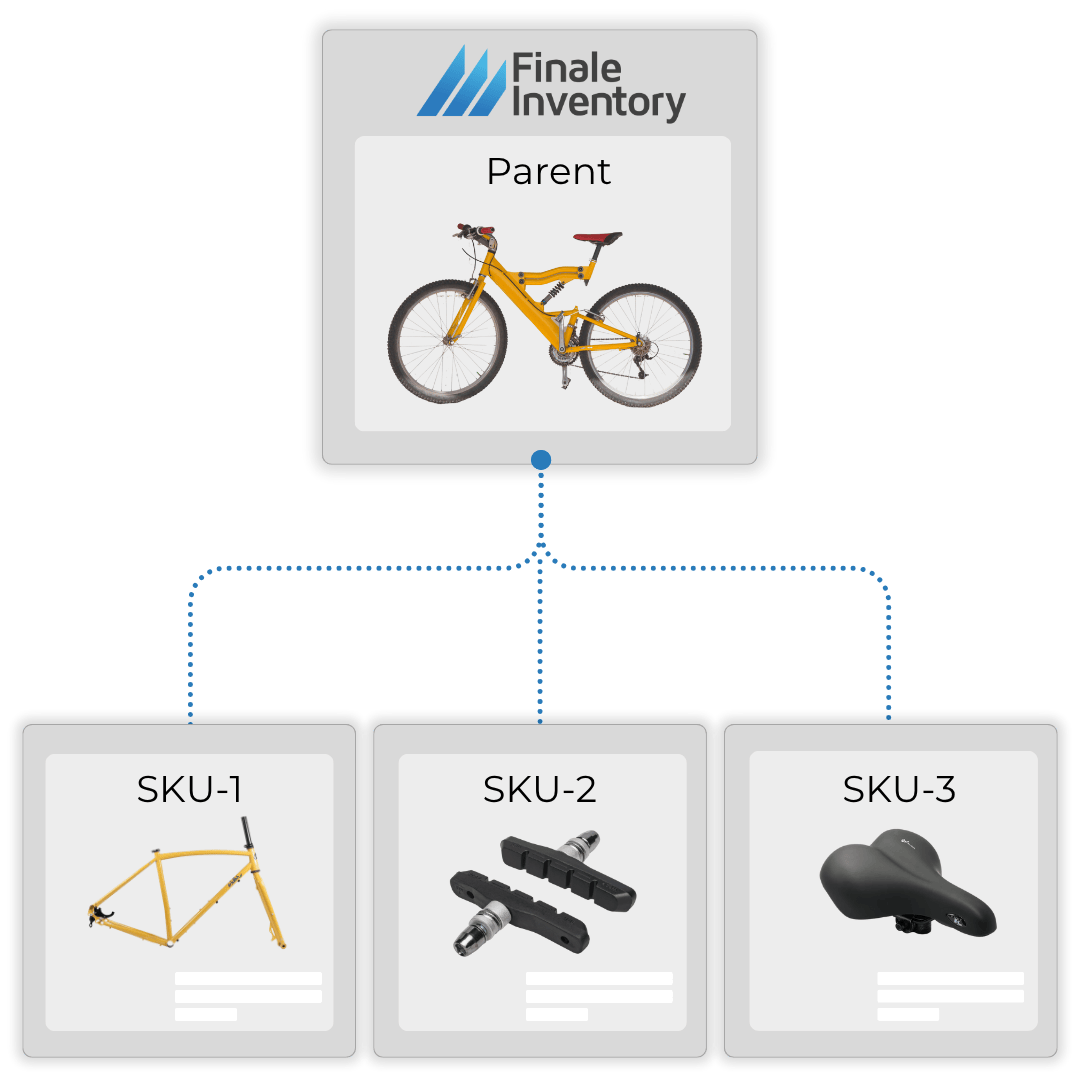

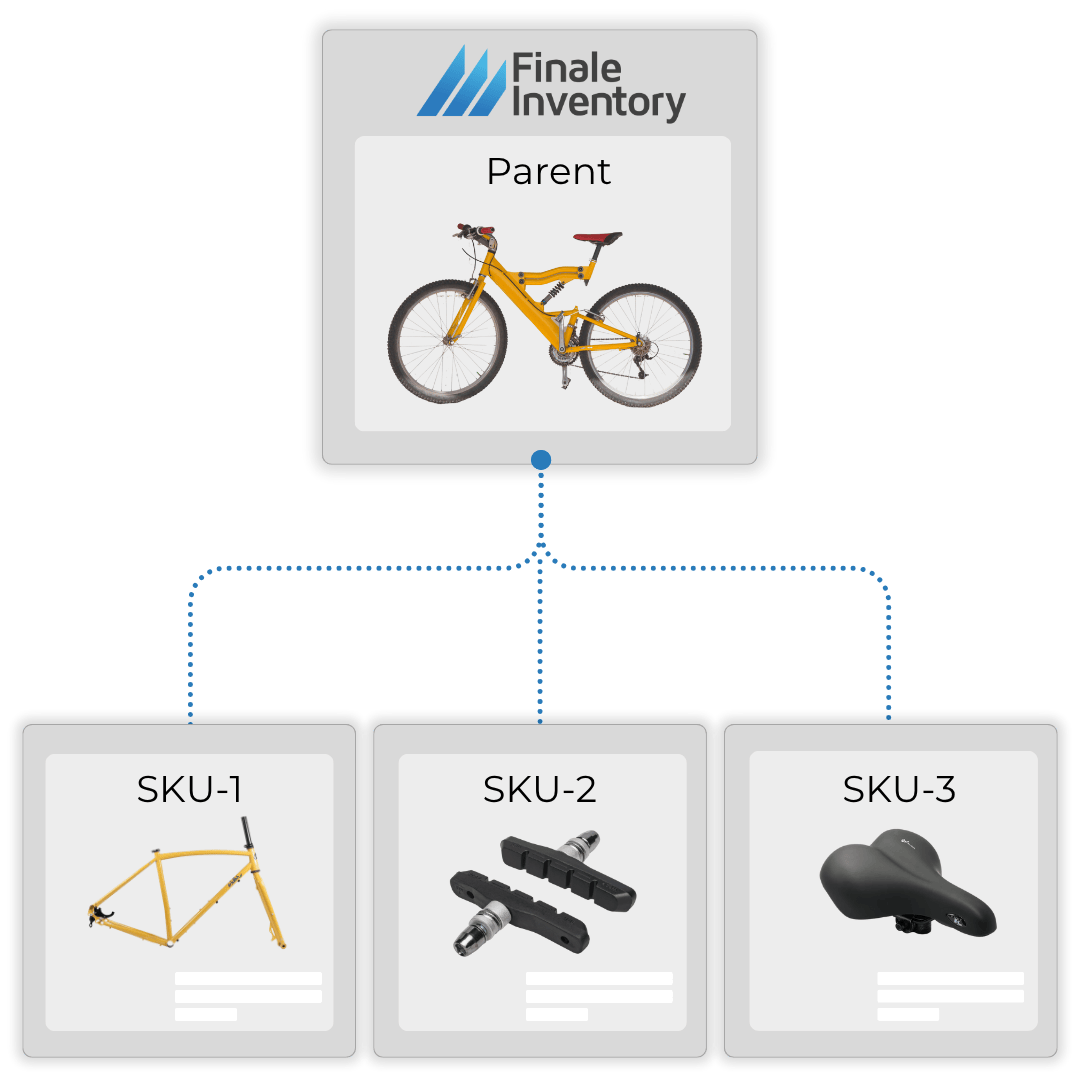

Bill of Material (BOM) software is an inventory management tool that lists all the parts, components, and raw materials required to build a product. Each item within a BOM is identified clearly by its unique product code or SKU, along with the exact quantity needed for production. Businesses use BOM software to accurately track inventory, streamline manufacturing processes, and effectively manage materials, reducing errors and optimizing resources.

- Lead time for materials and parts: The larger the order, the longer the lead time. Lead time tracking improves assembly or manufacturing scheduling.

- COGS accuracy to make sure you are actually staying profitable

- Minimum order quantity: account for bulk material or parts sourcing by taking advantage of larger, infrequent supply orders with a bulk discount, rather than buying individually. If you don’t use the whole quantities from a previous order, you need to be able to track the remaining components/parts/materials

- Vendor or supplier organization: If one supplier is not able to provide the materials, the BOM software will have the back-up supplier information available, so production is not slowed. The BOM software is where you log the approved vendor list (AVL) with contact information, price, and lead time.

- Accurate lead times and minimum order quantities give you more accurate cash flow insights for business decision-making. Manual data entry into Excel is not optimal for manufacturing and assembly, and especially for accurate COGS calculations.

- Product costing provides a clear picture of your margins, allowing you to price your product accurately based on its true cost.

Yes, in Finale's bill of material (BOM) software, you can fulfill an order with only the components. This setting is referred to as the expanded bill of materials. This means that when the order needs to be picked, the picker will see each SKU that needs to be assembled to complete a just-in-time assembly.

Without an expanded bill of materials, the picker will only be prompted to pick the final SKU of the preassembled unit. Either way, Finale will track and calculate the remaining parts, regardless of whether you fulfill with individual components/parts or with the finished good.

Yes, disable the expanded bill of materials (BOM) setting so the picker will be prompted to fulfill only the finished good. This is good-level picking for products that are pre-assembled before the fulfillment process.

Finale Inventory's bill of material (BOM) software is single-level.

Bill of materials (BOM) software helps with lean manufacturing by giving you the tools needed for bulk ordering and just-in-time production

- Bulk supply ordering: Often, when you order in bulk from a supplier, they will give you a discounted rate. Finale tracks your components and parts so you can plan ahead and receive the discounted order from the supplier

- JIT production: With BOM software, just-in-time production is possible, allowing you to keep your components and parts ready until the order needs to be fulfilled.

Finale Inventory is not a full Material Requirements Planning (MRP) or Enterprise Resource Planning (ERP) system, but it does include some lightweight MRP-style features for production management.

If you build a finished good, the SKU will appear in the reordering screen as a reorder recommendation. This will prompt you to build more of that product. Alternatively, Finale has the power to make a Build Shortage report identify which finished products are in short supply and whether you have sufficient raw materials to produce/build more.