Warehouse Management System

Gain Accuracy, Improve Operations

Streamline your warehouse workflow, boost productivity, and increase profit margins. Get your teams and warehouses aligned with Finale's warehouse management system (WMS).

Improve Warehouse Efficiency & Reduce Costs

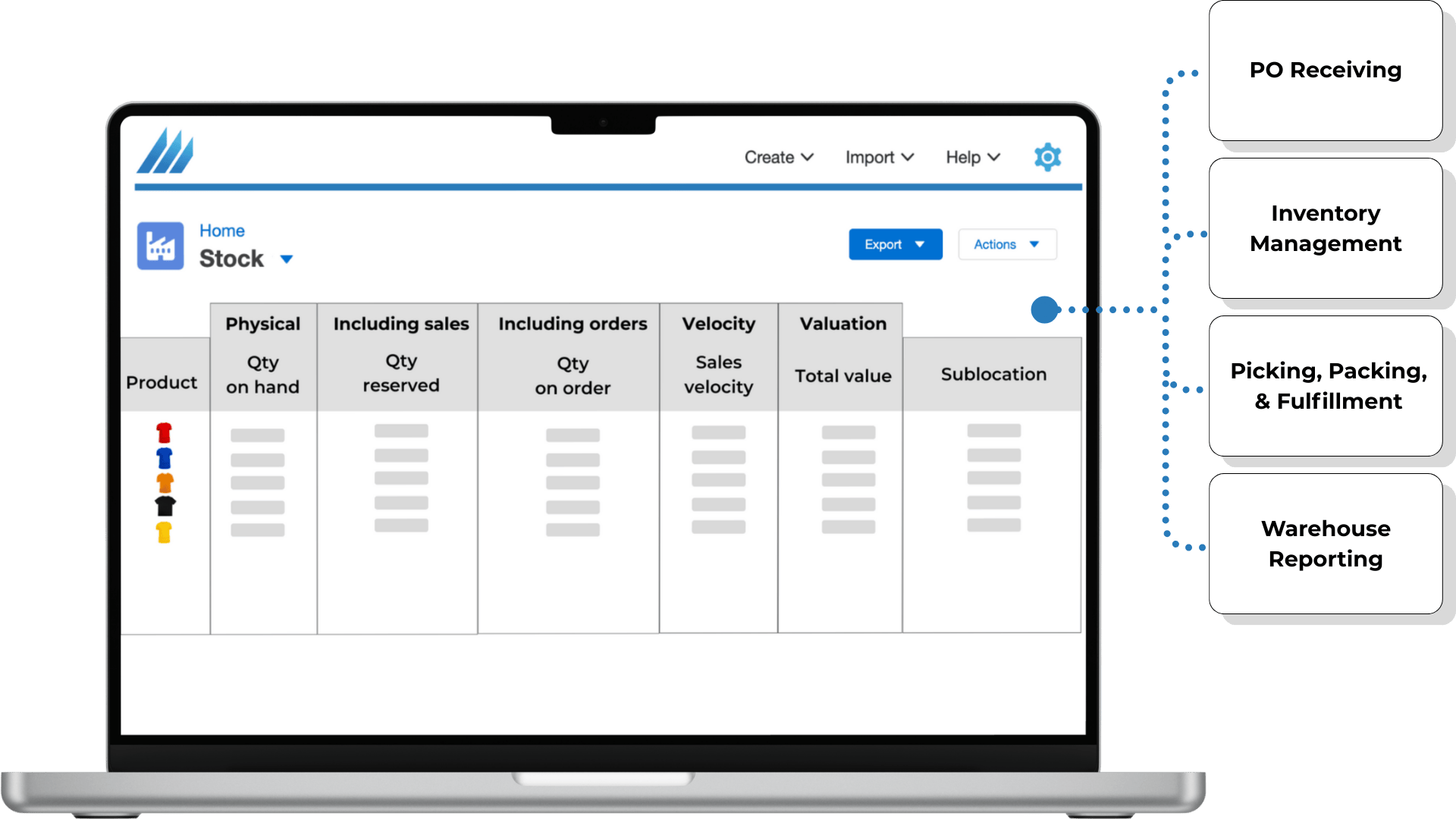

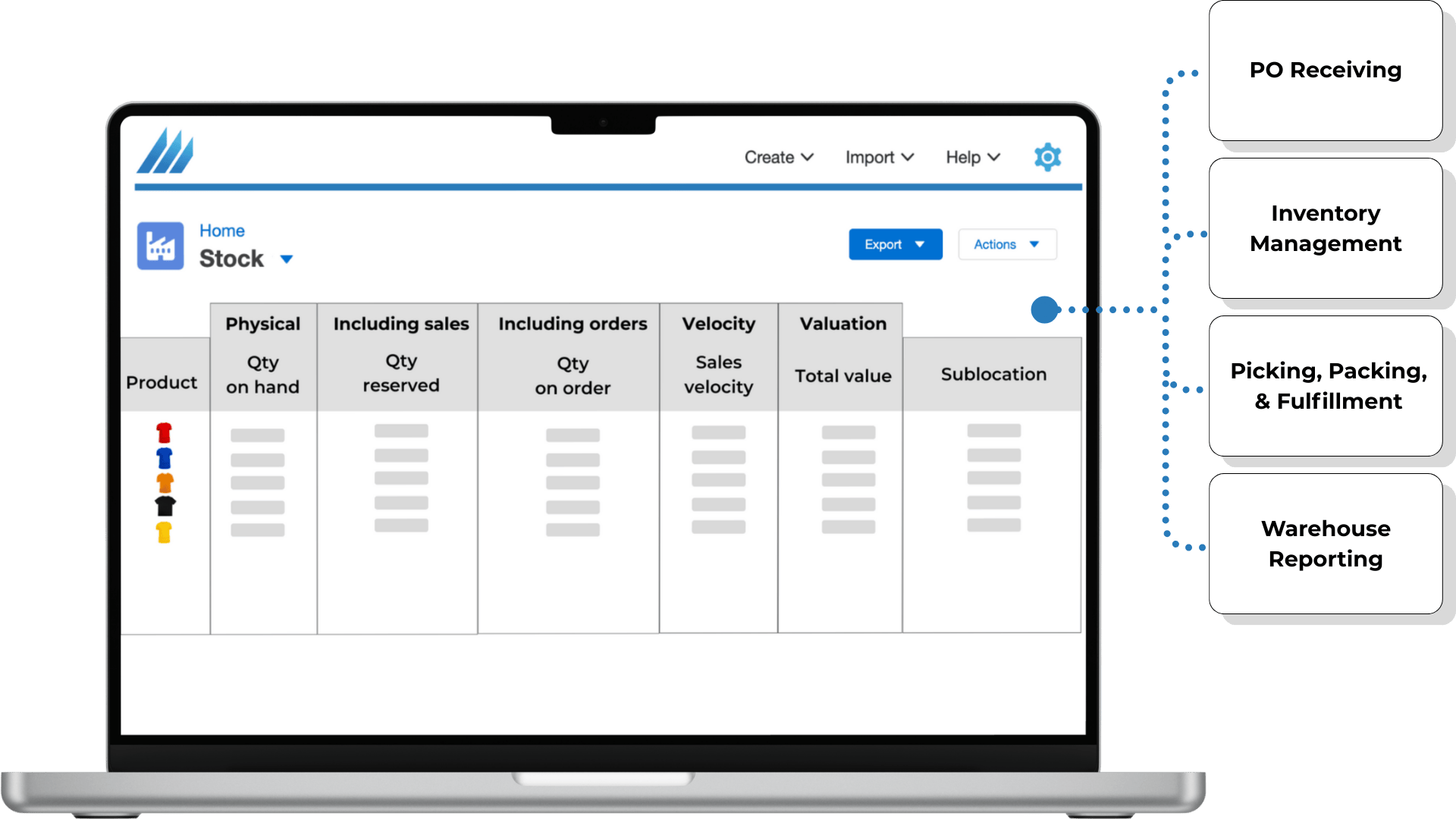

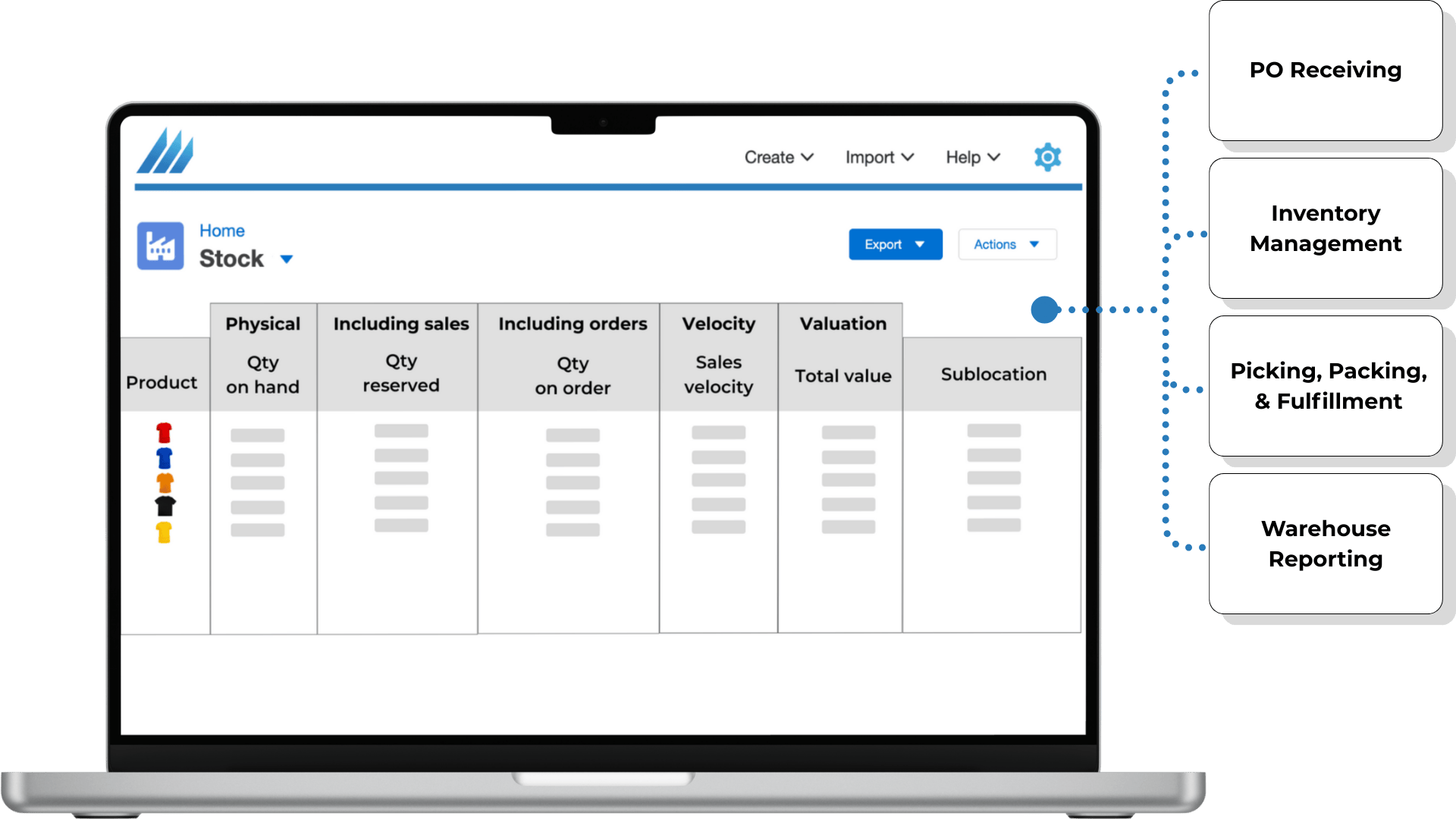

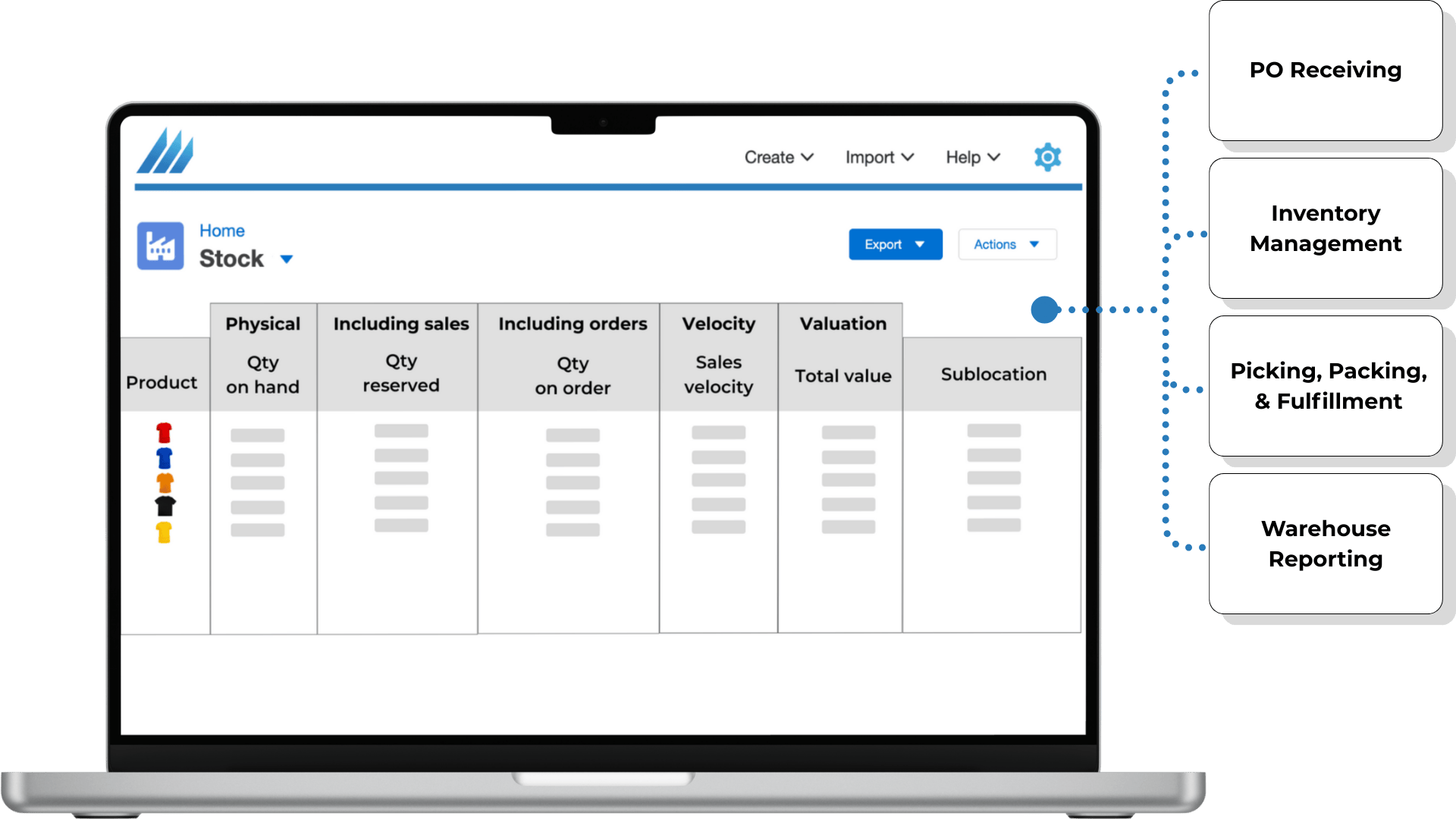

What Is a Warehouse Management System (WMS)?

Managing a growing inventory across multiple locations without a structured system can quickly lead to misplaced stock, delayed shipments, and costly mistakes. Many businesses struggle to maintain real-time visibility and control over their warehouse operations.

Finale Inventory’s warehouse management system brings your inventory, warehouse locations, and team operations into one unified platform. Whether you're managing a single warehouse or multiple sites, Finale helps you track every SKU, aisle, shelf, and shipment with precision.

Order Picking, Packing, & Fulfilment

Order fulfillment becomes chaotic when multiple sales channels, manual processes, and warehouse inefficiencies overlap, leading to wrong shipments, missed deadlines, and marketplaces showing the wrong availability.

Finale connects all your ecommerce platforms into one system and supports barcode scanning for fast, accurate order picking and packing. Use wave picking to batch orders together, saving time and reducing warehouse walking. This powerful barcode scanner system handles serial numbers, lot IDs, and expiration dates.

Receiving Shipments

Without a clear process for receiving inventory, stock often gets misplaced, delayed, or overlooked entirely. Items in transit or sitting on a loading dock can be forgotten, and without tracking, it’s hard to know what’s been received, what’s still en route, and what’s ready to go on the shelf.

Finale tracks inventory from when a purchase order is created through receiving, unloading, and put-away. Scan items as they arrive, manage returns, and assign them directly into bins to keep your stock organized. You can also scan items when loading or unloading trucks, and treat prep zones and loading docks as active inventory locations, so nothing goes missing, and you maintain full visibility from shipment to shelf.

Stock Replenishment

In high-volume warehouses, picking efficiency depends on keeping active bins fully stocked. Without a system to manage replenishment from overflow or backstock locations, pickers run into empty bins, fulfillment slows down, and errors become more frequent, especially during peak order volumes.

Finale automates stock replenishment by monitoring stock levels in the picking zones and triggering internal stock transfers when it’s time to restock. Move inventory from backstock or overflow zones to active picking bins with full traceability. This lean replenishment process helps maintain picking speed, reduces warehouse congestion, and keeps operations running smoothly at scale.

Finale Inventory. The Ultimate Warehouse Management System.

Warehouse Labeling System

Unorganized storage areas make it difficult for teams to locate inventory quickly, leading to slow picking times, inaccurate counts, and fulfillment delays.

Finale lets you label your warehouse with aisle, shelf, and bin locations using standard or QR barcode labels. Designate zones and storage areas so every item has a scannable, trackable home.

Warehouse Reporting

It’s hard to grow when you're making inventory decisions based on guesswork or outdated spreadsheets. Without clear reporting, it’s easy to miss trends, reorder too late, or tie up cash in the wrong products — and you never really know what your inventory is worth.

Finale’s reporting tools turn your inventory data into actionable insights. From reorder alerts and restock planning to forecasting based on real-time sales velocity, Finale helps you stay one step ahead and keep your inventory lean, accurate, and profitable. Get visibility into stock valuation — by SKU, product category, or warehouse location — so you can make smarter, more profitable decisions.

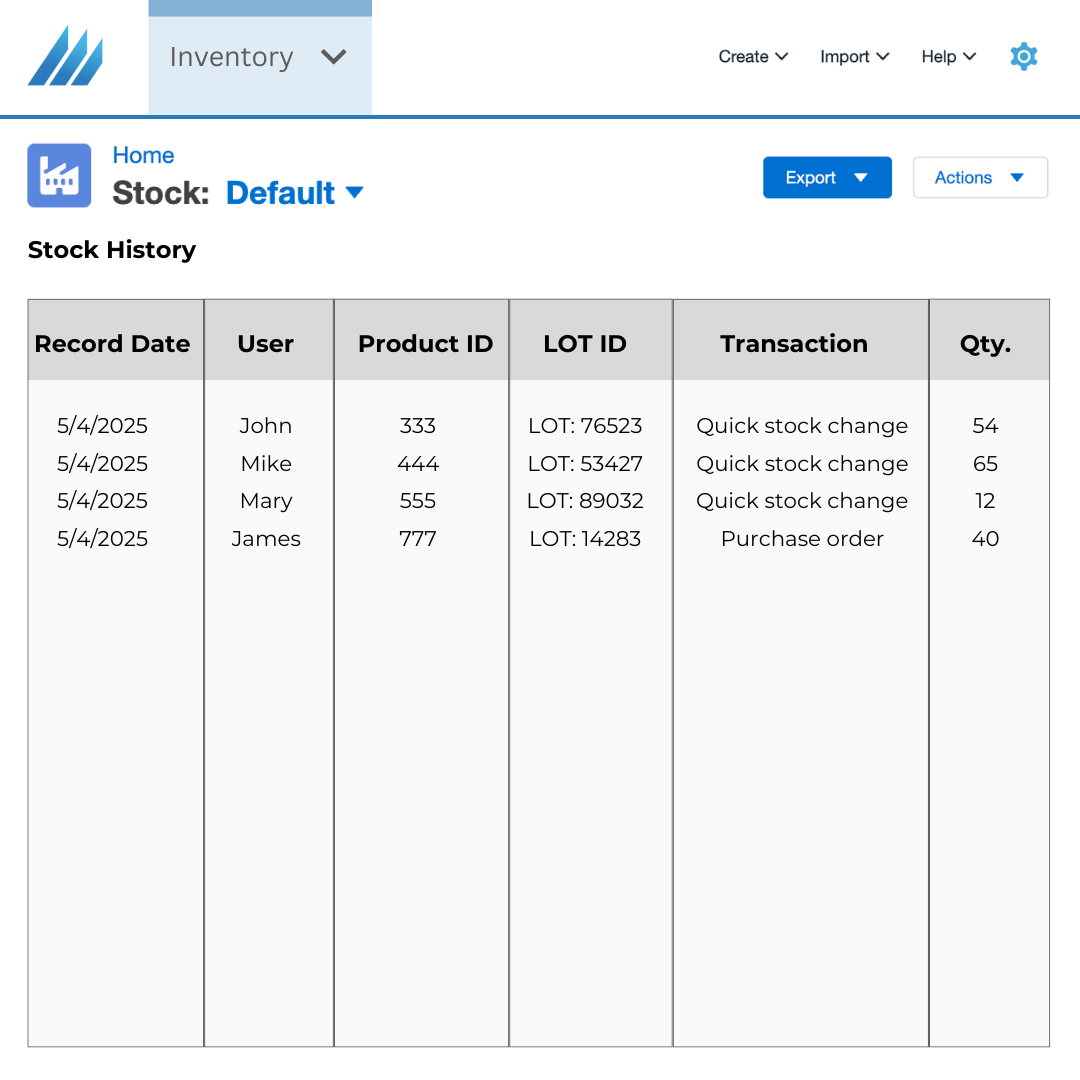

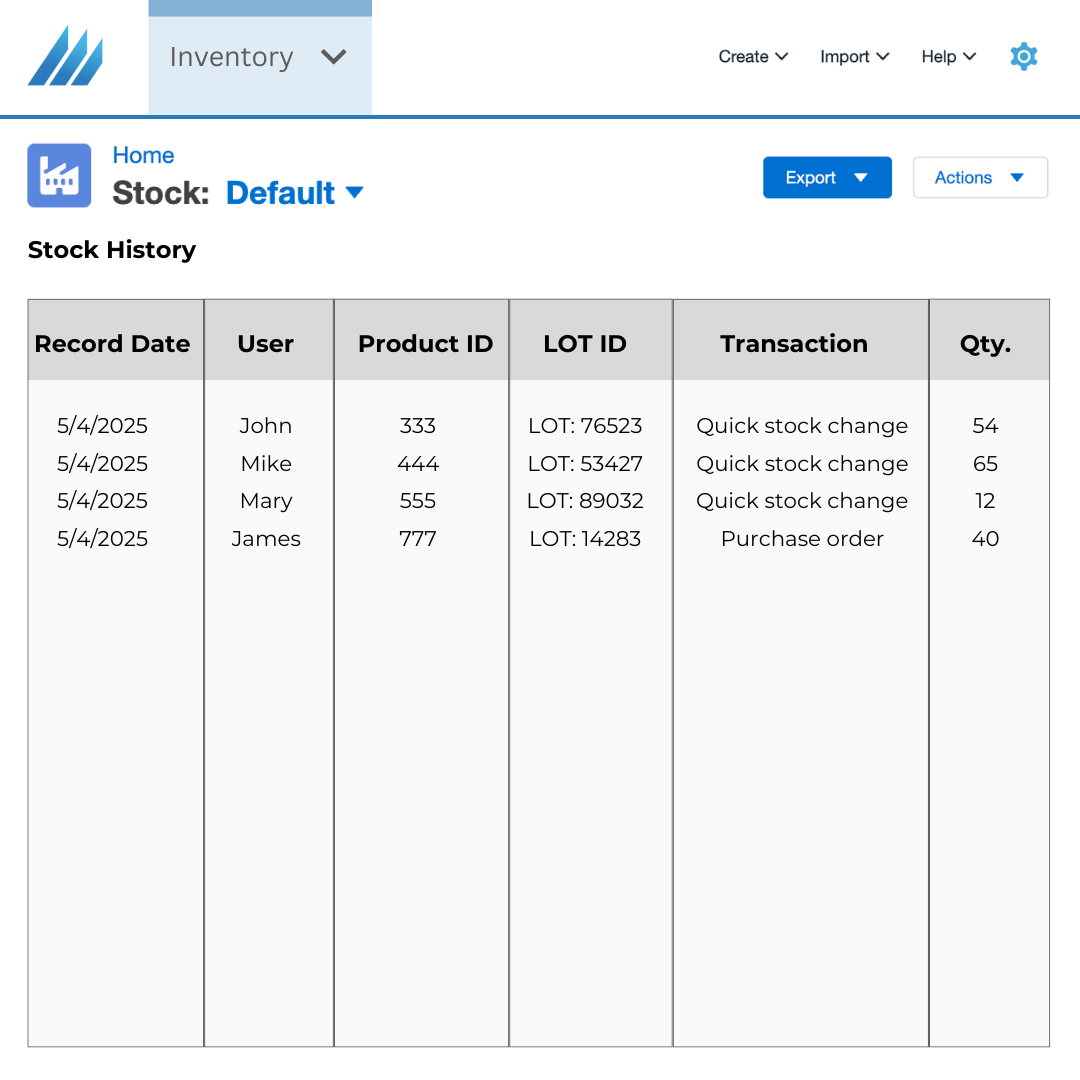

User History Log

In high-volume or large warehouse operations, pick and pack tasks involve multiple workers handling dozens — even hundreds — of orders at once. Without a structured warehouse management system, it’s nearly impossible to track this.

Finale Inventory supports complex pick and pack workflows for a bulk fulfillment process. Whether it’s picking, packing, stock transfers, or cycle counts, Finale records who did what and when. This level of visibility is critical for managing large teams, reducing errors, and ensuring accountability across your warehouse floor.

Shipping

Finale integrates directly with shipping tools like ShipStation, ensuring seamless sync between orders, inventory, and carrier labels. Scale operations and sync your shipping software to Finale, the inventory hub.

"It's fair to say that our picking accuracy is much improved since implementing barcode scanning. We make very few picking errors anymore. In our manual-visual days, we had an overall pick error rate of about 2%, but it's well under 1% now -- only about 3 errors in 1,000 orders."

A warehouse management system (WMS) helps businesses track inventory across all stages of the warehouse process — receiving, storing, picking, packing, and shipping. It creates structure and visibility so teams can work more efficiently and avoid costly errors. Finale Inventory’s WMS gives you real-time visibility into your inventory across every location — whether it’s sitting on a shelf, in a prep zone, or in transit. With powerful SKU management and multi-warehouse tracking, you’ll always know what you have, where it is, and what needs attention.

Watch step-by-step videos on inventory and warehouse operations using Finale.

Choosing the right warehouse management system involves evaluating several factors, including the cost of onboarding, implementation, and training. It’s also crucial to consider the reputation of the software’s customer service team, as effective support can make or break your experience, especially when you're scaling or dealing with complex operations.

Finale offers a cost-effective solution with a straightforward onboarding process and ongoing training resources to ensure your team gets up to speed quickly. With a reputation for excellent customer support, Finale helps you implement and maintain a smooth-running warehouse system, giving you peace of mind as your business grows.

- Aisle, shelf, and bin label system

- Receiving and put-away process

- Inventory management

- Order picking, packing, and fulfilment process

- Stock movement and user history log

- In transit, dock, and zone tracking and management

- Shipping software integrations

- Customizable reporting and alerts

- Scalability and flexibility: Easily upgrade or downgrade as your business needs change — add users, warehouses, or SKUs without switching systems.

- Cost efficiency: Eliminate the need for expensive on-site servers or IT infrastructure, keeping overhead low and predictable.

- Accessibility and integration: Access your WMS from anywhere and connect it with your ecommerce platforms, shipping tools, and accounting software.

- Enhanced security and disaster recovery: Cloud systems offer built-in data protection, backups, and uptime monitoring to keep your operation running smoothly.

- Real-time updates: Inventory and order data sync instantly, so your team always has the most accurate information — no matter where they are.

Finale's cloud-based system checks all these boxes, giving growing ecommerce and warehouse teams the flexibility, connectivity, and reliability they need to operate at scale.

The average cost of an ERP system used for warehouse management typically ranges from $1,500 to $10,000+ per month, depending on the number of users, warehouse locations, and level of customization required. These systems often come with additional implementation fees, which can cost tens of thousands of dollars up front.

Finale offers a more affordable and flexible alternative, with plans starting at a fraction of the cost. You get powerful warehouse management with the support of experts. See Finale in action on a live demo call.

The first step you’ll need to do is import all of your SKUs for your products. Next, you’ll have to record the current stock levels of these SKUs, if you know this information. Input all your warehouse, retail, and storage locations. After that, label your bins, shelves, and zones with barcode labels. If you’re an ecommerce seller, you’ll then need to connect all your selling channels and marketplaces to the warehouse management system (WMS). After that, connect your shipping system. Next, import your supplier(s) and wholesale customer(s) into the system. One step to not forget about is inputting your cost of goods sold (COGS), lead time, and report point thresholds.

There are more steps to making sure you get the full benefit from your warehouse management system (WMS) but these are the first steps to take when you set up.