Lot ID Tracking System

Lot Tracking Software for Traceability

Finale Inventory’s Lot ID Tracking System is a robust lot-tracking software that ensures precise traceability and compliance for manufacturing operations. Keep your processes efficient and your data reliable with advanced tracking tools.

Traceability for Quality Assurance, Recalls, and Risk Mitigation

What Is a Lot Number?

A lot number, also known as a batch number, is a unique identifier assigned to a specific quantity of goods produced or received together under the same conditions. It is used to track and trace products through various stages of production, storage, and distribution. Lot numbers are essential in industries like manufacturing, automotive parts, and pharmaceuticals, where precise traceability is critical for quality control, regulatory compliance, and managing recalls. By assigning a lot number, businesses can monitor the origin, production date, and movement of a group of items, ensuring accountability and transparency in their inventory processes.

Industries That Use Lot Numbers That Are Highly Regulated or with Specialized Products

Food: Where managing expiration dates, perishability, and batch recalls is vital. Track expiration dates to ensure perishable items are sold before they spoil, and trace lot ids to manage recalls efficiently if a product is found to be contaminated.

Cosmetics, Health, and Beauty: Most cosmetic good manufacturing practice guidelines require a lot or batch number. Lots are used to track batches of products with color additives, expiration dates, active ingredients, and much more.

CBD: Depending on your state and CBD strength, you may be required to track manufacturer batches; this is done with lot id tracking. In addition, this lets you see the creation date or strains. Finale ensures clear traceability of your products from receiving the shipment to order fulfillment.

Fireworks: A high-risk industry where safety, regulatory compliance, and precise tracking of products (such as by batch ID and serial number) are essential to prevent accidents and ensure quality. Track the lot id, serial numbers, and safety certifications for each batch of fireworks, ensuring ATF compliance.

Track, Manage, and Oversee Groups of Products. Trace Products From Their Source

A batch tracking software is designed to help businesses track, manage, and oversee groups of products or materials throughout the manufacturing and supply chain process.

Batch tracking isn’t just for batch manufacturing—it’s also crucial for manufacturing and businesses managing various workflows. With a robust batch management solution like Finale Inventory, you can:

- Monitor expiration dates to prevent inventory waste

- Pinpoint defective items back to their production batch for swift action

- Streamline product recall processes for faster resolutions

- Meet industry regulations and compliance standards effortlessly

Traceability Software for Manufacturing

Lot tracking helps businesses comply with regulations that require manufacturers to maintain detailed records of their products and processes.

Gain End-to-End Traceability: From receiving products to shipping them out, tracking specific items from purchase orders (POs) to sales orders (SOs) ensures that you always know where your stock is and what its status is at each stage of the process. This is especially important in industries where strict regulations require you to maintain precise records of product movements.

Transfers and Warehouse Management: If you operate multiple warehouses, being able to track inventory transfers across different locations helps maintain stock levels and ensure safe storage practices. This is critical in industries like fireworks, where specific storage conditions (like temperature and safety protocols) must be adhered to by ATF regulations.

Leverage Barcoding Scanning to Easily Track Lot Numbers

Lot IDs are typically assigned when products arrive at the warehouse, and Finale streamlines this process by offering multiple options for entering Lot ID information.

While some users prefer manual updates or bulk importing, most rely on Finale’s mobile barcode scanning solution.

By simply scanning a Lot ID barcode upon receiving a purchase order and again when transferring stock or shipping orders, Finale ensures full traceability.

Don’t have barcoded products? No problem—Finale can create and print custom barcode labels right within the system.

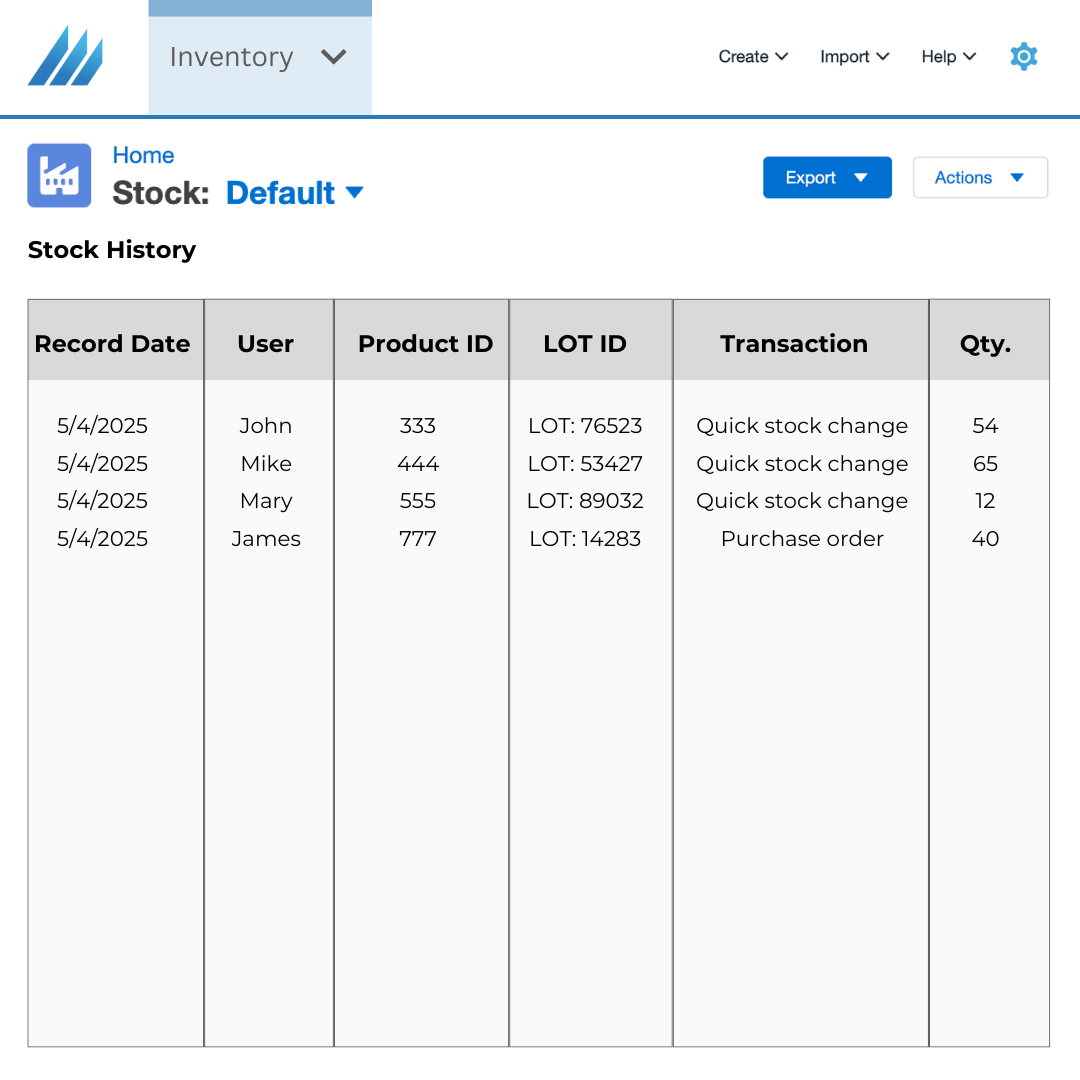

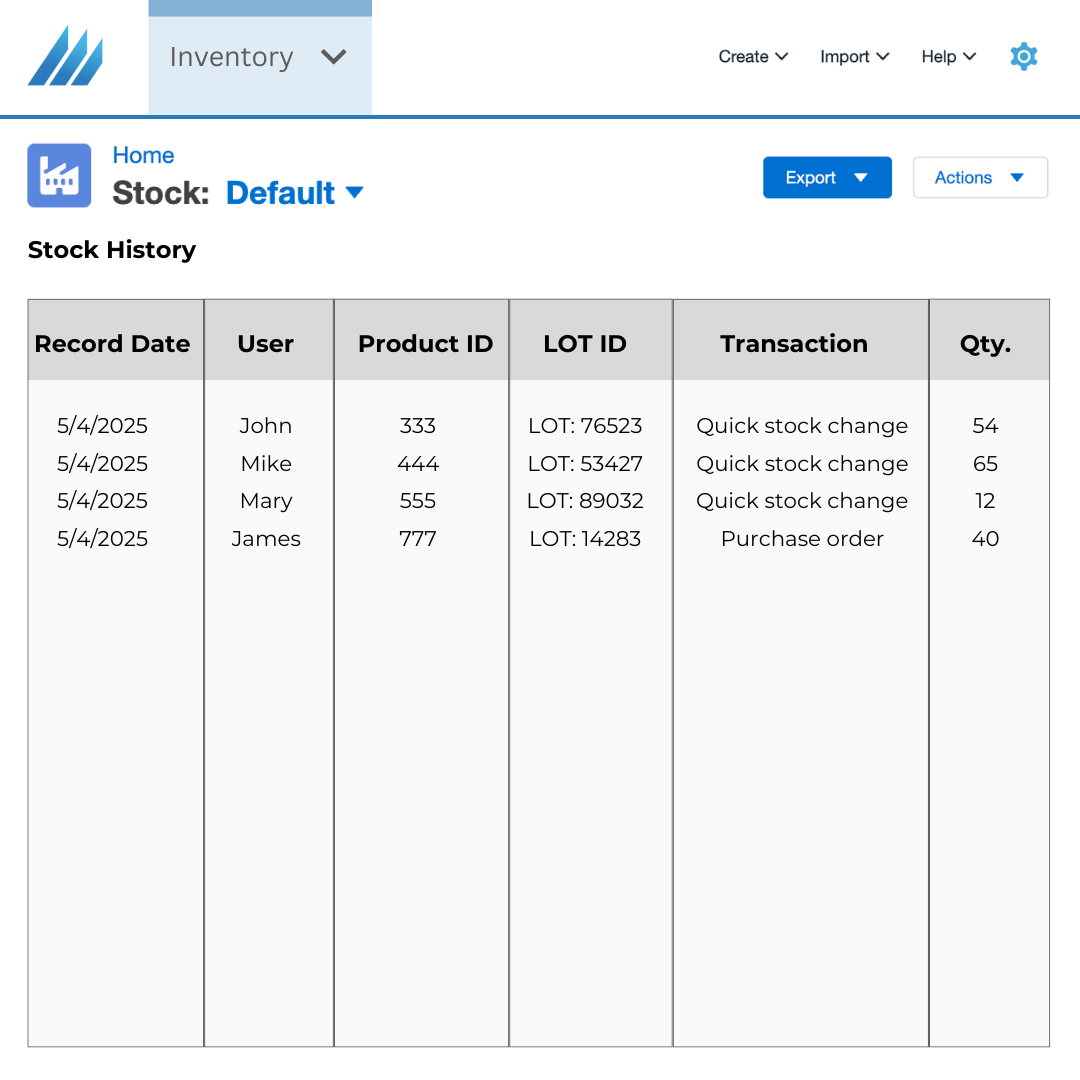

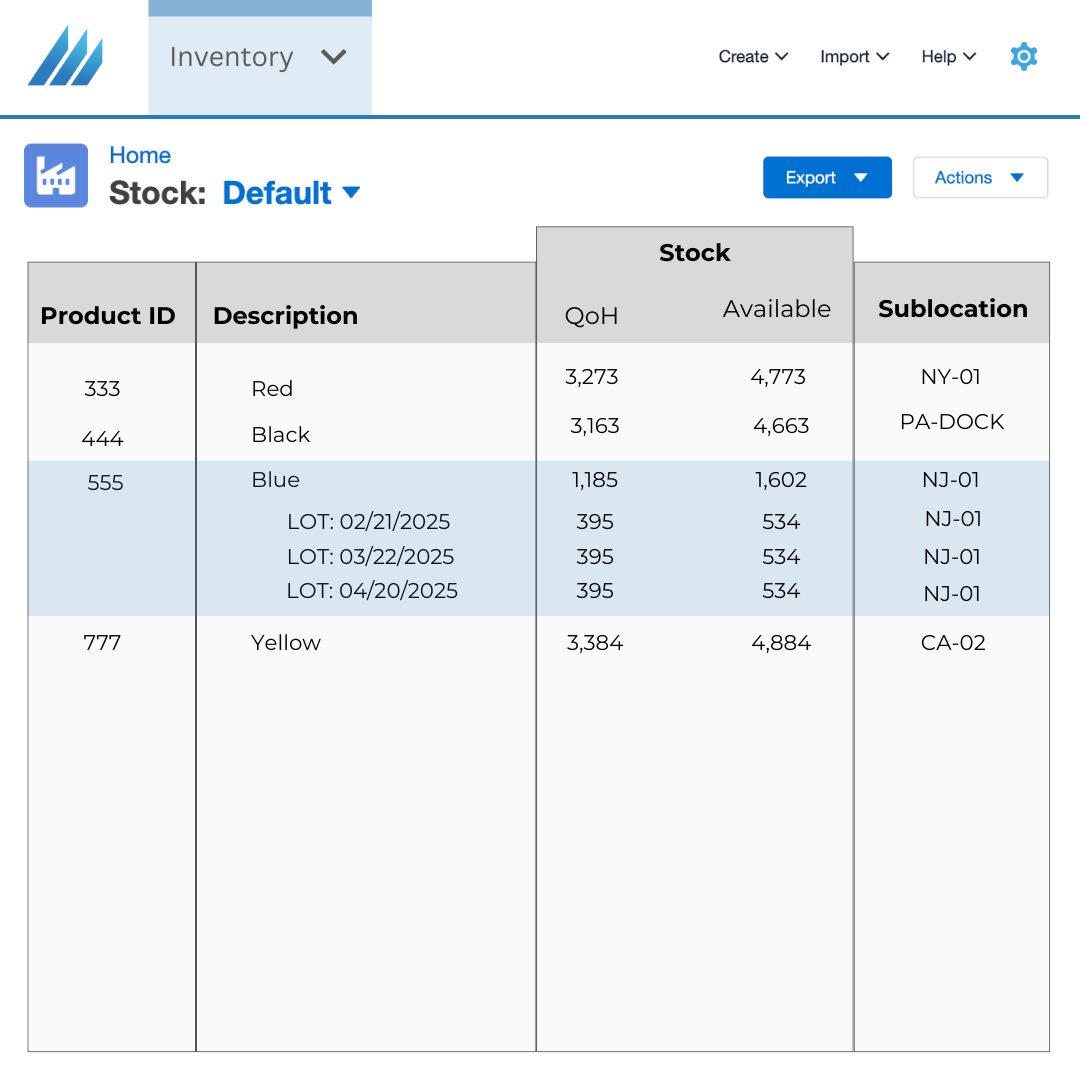

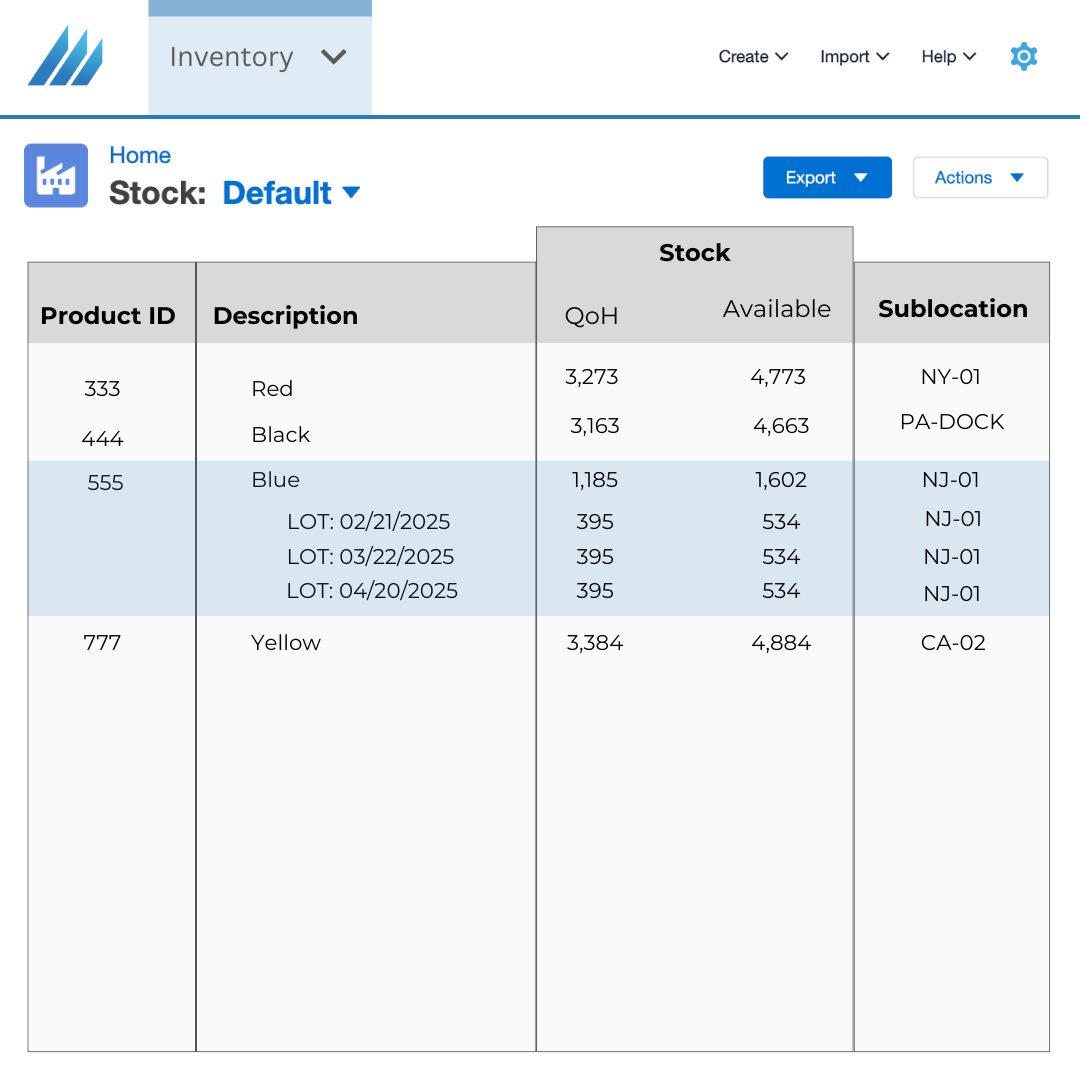

Powerful Screens to Track Lot ID and Batch Numbers

Finale’s stock screen easily conforms to a business that uses lot ID and batch numbers. Our team is here to help customize your screens to help you get the information that is most important for you and your business

Traceability for Regulatory Compliance: Reports with lot id information allow businesses to demonstrate full traceability of their products, ensuring they meet local, state, and federal regulations. This is particularly important in industries like fireworks, where safety and legal compliance are non-negotiable.

Some common inventory reports include

- Export lot ID per SKU

- Search stock by product or lot ID

- Stock quantity by sublocation with lot ID

"We are part of a university research lab group that uses Finale to track supplies of biospecimen collection kits (builds) and lab supplies. The ability to create builds (to track individual components) for our kits is wonderful! Also, the ability to track lot identifiers and expiration dates is critical for lab reagents and things like blood collection vials."

Yes, you can have a lot ID associated with a product in addition to a serial number. The lot ID will track which batch it was produced in while the serial number will track the individual item.

Barcodes can represent Lot IDs, but they don't have to. Some companies find it easier to use barcodes that represent only the Product IDs, and to specify the Lot ID separately. Other companies use barcodes that represent the Product ID, Lot ID, and possibly even the suggested packing altogether.

Learn more about how the barcode scanner and lot IDs interact.

Yes, you can copy and paste from a spreadsheet to import in bulk.

If your product requires lot or serial number tracking, three columns are required in the Excel file.

Column 1: Product ID

Column 2: Lot ID

Column 3: Qty