Retail Inventory Management: 15 Best Practices for 2025

Retail inventory management is a fundamental part of running a successful ecommerce business. With the evolving landscape of online retail, staying ahead is crucial. Effective strategies can optimize inventory control and enhance overall efficiency. This article outlines key aspects of retail inventory management and future trends shaping the industry. It also offers 15 best practices for 2025 to ensure smooth inventory management.

What is Retail Inventory Management?

To grasp the importance of retail inventory management, it’s essential to understand its core principles. Essentially, inventory management involves overseeing the flow of goods from procurement to customer sales. This includes tasks such as stock monitoring, replenishment, forecasting, and maintaining optimal stock levels in warehouses or distribution centers.

The Importance of Effective Inventory Management

Effective inventory management is key to the success of any ecommerce business. By managing inventory efficiently, you can reduce stockouts, prevent overstocking, lower carrying costs, and enhance customer satisfaction. It allows you to remain competitive in a fast-paced market and meet the demands of today’s discerning online shoppers.

How Do you Keep Track of Retail Inventory?

For effective retail inventory management, consider these essential components:

- Accurate Demand Forecasting: Use advanced forecasting techniques to predict customer demand accurately. This helps adjust inventory levels, reducing the risk of stockouts and overstocking.

- Real-Time Monitoring: Employ technology to monitor inventory in real time. Automated systems can track stock levels, sales trends, and support data-driven decisions.

- Efficient Replenishment: Implement strategies to ensure products are available at the right time. Utilize automated reorder systems and build strong supplier relationships for a streamlined reordering process.

- Streamlined Fulfillment: Optimize your order fulfillment to ensure timely deliveries and reduce errors. Efficient fulfillment improves customer satisfaction and operational efficiency.

- Inventory Turnover: Focus on enhancing inventory turnover to avoid high carrying costs. Strategies like discounting slow-moving items or promotions can help move stagnant inventory quickly.

- Data Analytics: Use data analytics tools to understand inventory performance. Analyzing sales patterns, customer preferences, and market trends helps in making informed inventory decisions and identifying growth opportunities.

Accurate demand forecasting is vital for managing inventory. By predicting customer demand with precision, you can adjust inventory levels to meet customer needs and maximize sales.

Real-time monitoring is another critical aspect. Implementing automated systems allows you to track inventory levels, monitor sales trends, and make quick, informed decisions, keeping you ahead of the competition.

Retail Inventory Management Examples

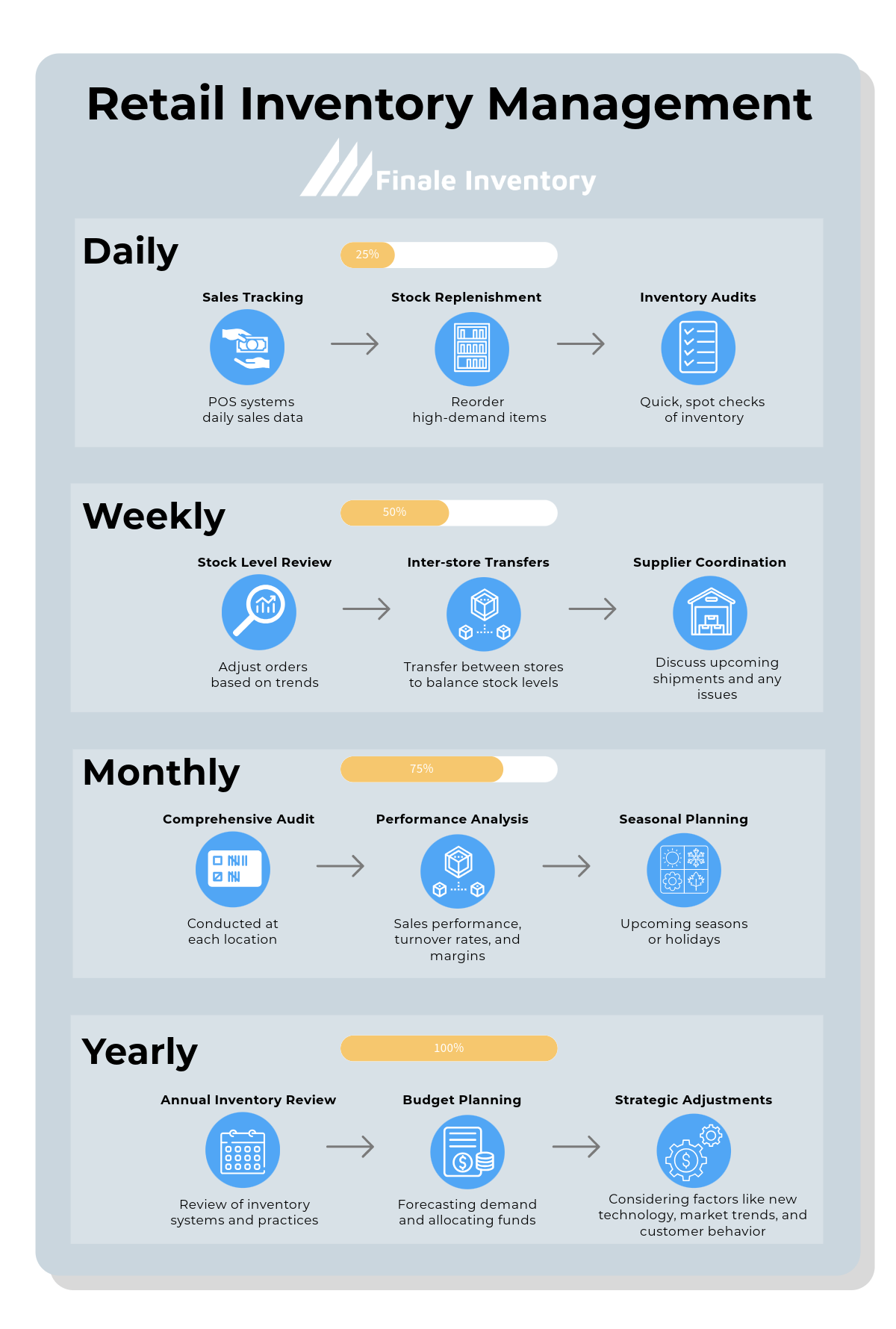

These are some examples of practices you should be doing on a daily, weekly, monthly, and annual basis to have your stock in check. These steps could be a manual prosses in Exel or an IMS.

Daily Basis

Sales Tracking: Each store records daily sales data, which is crucial for understanding demand and adjusting stock levels. This involves using POS systems to track what items are selling and at what rate.

Stock Replenishment: Based on daily sales data, store managers might reorder high-demand items from the central warehouse or supplier to ensure shelves remain stocked.

Inventory Audits: Quick, spot checks of inventory levels help identify any discrepancies or issues early. This can include checking for misplaced items or signs of theft.

Weekly Basis

Stock Level Review: At the end of each week, store managers review inventory levels compared to sales data. They adjust orders based on trends and upcoming promotions or seasonal changes.

Inter-store Transfers: If one location has excess stock of certain items and another location is running low, managers might transfer inventory between stores to balance stock levels.

Supplier Coordination: Weekly meetings or communications with suppliers to discuss upcoming shipments and any issues with stock levels help ensure that inventory arrives on time and meets demand.

Monthly Basis

Comprehensive Inventory Audit: A more thorough inventory count is conducted at each location to reconcile physical stock with records. This helps catch and correct any discrepancies that might have developed.

Performance Analysis: Monthly reports analyze sales performance, inventory turnover rates, and profit margins. These insights guide future purchasing decisions and promotional strategies.

Seasonal Planning: Managers prepare for upcoming seasons or holidays by adjusting inventory orders and marketing strategies based on expected trends and customer preferences.

Yearly Basis

Annual Inventory Review: A complete review of inventory systems and practices is conducted to identify areas for improvement. This includes evaluating supplier performance and inventory turnover rates.

Budget Planning: Based on the year’s performance, budgets for inventory purchases are set for the upcoming year. This involves forecasting demand and allocating funds accordingly.

Strategic Adjustments: The store might review and adjust its overall inventory management strategy, considering factors like new technology, market trends, and changes in customer behavior.

By following this example, retail stores can effectively manage inventory across multiple locations, ensuring that they meet customer demand while minimizing excess stock and associated costs.

Demand Forecasting: Predicted Changes in Consumer Behavior

Demand forecasting is the process of using business sales data from the past months and years to make a calculated estimate of your future customer demand for your products for a specific period.

For example, as an inventory manager, based on your analysis of your past sales data, key sales trends in your market, and other factors, you can predict a 30% increase in the demand for your product for the next quarter. Your ability to do this — as accurately as you can — benefits your business in a number of ways.

Knowing the right amount of inventory to stock ensures you do not waste your business funds on inventory holding costs. Also, demand forecasting helps you effectively allocate your business resources to help you achieve your goals and save on operating costs.

15 Best Practices for Retail Inventory Management in 2025

For 2025, effective inventory management remains crucial. Implement these 15 best practices:

- Embracing Automation in Inventory Management: Use automation tools to streamline tracking, purchasing, and order fulfillment. Automation improves accuracy and efficiency while reducing human errors.

- Prioritizing Accuracy in Stock Levels: Regularly update and reconcile stock levels to ensure data accuracy, avoiding discrepancies between physical inventory and recorded data.

- Leveraging Real-Time Data for Inventory Decisions: Utilize real-time data analytics for timely and informed inventory decisions. Track inventory metrics effectively with key performance indicators and dashboards.

- Implementing Efficient Inventory Turnover Strategies: Optimize turnover by addressing slow-moving items with strategies like discounts, bundled deals, or repackaging.

- Fostering Supplier Relationships for Better Inventory Control: Build strong supplier relationships for efficient supply chains. Regular communication and collaboration improve inventory management.

- Utilizing Cross-Docking to Improve Inventory Management: Implement cross-docking to minimize storage costs and expedite order fulfillment. This method reduces long-term warehousing needs.

- Adopting a Centralized Inventory Management System: Centralize inventory management by integrating it with sales and purchasing operations. This enhances visibility and simplifies control.

- The Importance of Regular Audits in Inventory Management: Conduct physical inventory audits regularly to ensure accuracy and identify discrepancies, maintaining data integrity and preventing losses.

- The Role of Demand Forecasting in Inventory Management: Invest in advanced forecasting tools to accurately predict demand, minimizing stockouts and overstocking.

- The Impact of Just-In-Time Inventory Management: Implement just-in-time practices to reduce carrying costs by replenishing stock only when necessary, optimizing cash flow, and cutting storage expenses.

- The Benefits of Dropshipping for Inventory Management: Explore dropshipping to reduce upfront inventory investments and avoid managing storage and shipping. Focus on marketing and customer service instead.

- The Significance of Safety Stock in Inventory Management: Maintain safety stock levels to handle unexpected demand fluctuations or supply chain disruptions. This buffer prevents stockouts during peak periods.

- The Advantages of Vendor-Managed Inventory: Collaborate with vendors to use vendor-managed inventory systems. Vendors handle stock monitoring and replenishment on your behalf.

- The Effectiveness of ABC Categorization in Inventory Management: Use ABC categorization to classify inventory by value, prioritizing management efforts on high-value items requiring strategic planning.

- The Value of Consignment Inventory in Retail Management: Consider consignment inventory to lower upfront costs. Pay for products only after they are sold, improving cash flow and reducing holding costs.

By adopting these practices, ecommerce businesses can refine their inventory management strategies and succeed in 2025 and beyond. Remember, inventory management is an ongoing process that demands continuous evaluation and improvement. Stay proactive and adapt to industry trends to maintain a competitive edge and meet the evolving needs of online shoppers.

As technology advances, new trends in inventory management emerge. AI in forecasting analyzes historical data, market trends, and customer behavior to predict demand more accurately. Blockchain technology enhances supply chain transparency and security, improving trust and efficiency. Sustainability is also a growing focus, with eco-friendly practices and reverse logistics becoming more common.

Stay informed about these trends and technologies. Educate yourself and your team, attend industry conferences, and network with professionals to exchange insights. This proactive approach positions your business for long-term success in the dynamic retail environment.

Retail Inventory Management Software

When managing inventory for just one store, Excel can be a practical solution. It allows you to track stock levels and sales in a simple spreadsheet. However, as your business grows with multiple locations, warehouses, and online sales channels, Excel’s limitations become clear. At this stage, investing in retail software development and an inventory management system (IMS) can provide more robust options to manage complex inventory and ecommerce needs.

Challenges with Excel

Complexity: Managing inventory across various locations can lead to cumbersome spreadsheets and errors. Real-time Updates: Excel lacks real-time synchronization, making it hard to get accurate, up-to-date inventory data. Scalability: As your operations expand, Excel’s basic features become inadequate for effective inventory management.

This is where specialized software like Finale Inventory comes in.

Automation with Finale Inventory.

Finale Inventory is a cloud-based solution designed to handle complex inventory needs efficiently. Here’s how it helps:

Centralized Tracking: Manage inventory across all locations and channels from a single dashboard. Real-Time Syncing: Automatically updates stock levels across all sites with each sale.

Automation: Streamlines tasks like reordering and reporting, reducing manual effort. Integration: Connects with various sales channels and marketplaces, ensuring seamless data synchronization. Advanced Reporting: Provides detailed insights on sales and inventory performance to guide decision-making.

With Finale Inventory, retailers can move beyond Excel’s limitations to achieve more efficient and accurate inventory management. Plus, Excel can’t give you a US-based world-class customer service and deep insights into business operations.

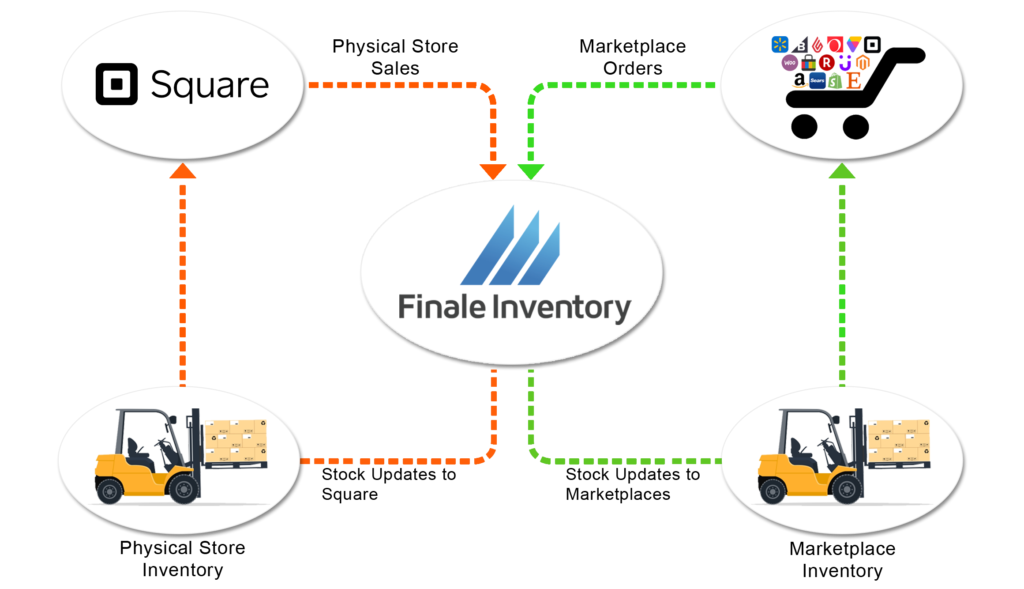

Square POS Integration with Finale Inventory

The Square integration with Finale Inventory allows you to synchronize your Square POS system with Finale Inventory, streamlining your inventory management. This integration automatically updates inventory levels in Finale Inventory based on sales and transactions processed through Square. It helps ensure that stock levels are accurate across all platforms, reduces manual data entry, and provides real-time insights into your inventory and sales performance. This seamless connection improves efficiency and accuracy in managing inventory across your retail operations.

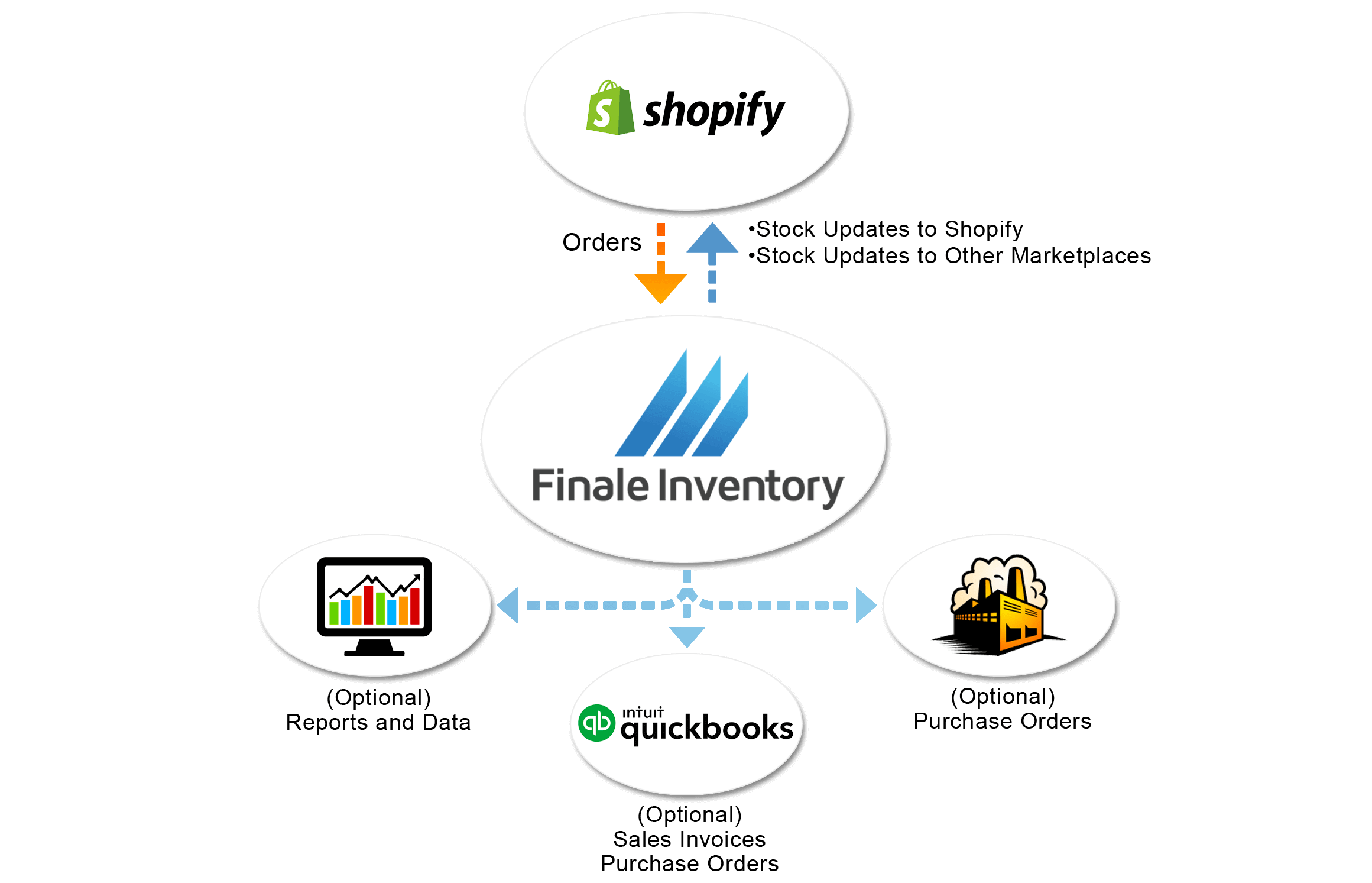

Shopify POS Integration with Finale Inventory

The Shopify POS integration with Finale Inventory connects your Shopify Point of Sale system with Finale Inventory, creating a unified inventory management solution. This integration allows for automatic synchronization of inventory levels between your physical store and your Shopify online store. This allows for real-time updates, streamlined operations, improved accuracy, and comprehensive reporting.

Transform Your Inventory with Finale

By adopting best practices such as automation, real-time tracking, and strategic forecasting, you can enhance efficiency, minimize errors, and better meet customer demands. Leveraging advanced tools like Finale Inventory and integrating them with your POS systems, such as Square and Shopify, provides a comprehensive solution for managing inventory across multiple locations and channels.

Request a Free consultation (valued at $2,500) and let us address your biggest inventory management challenges with Finale Inventory. Experience the difference Finale Inventory can make for your business.